POWER UP A WINNER - Plant Services

POWER UP A WINNER - Plant Services

POWER UP A WINNER - Plant Services

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

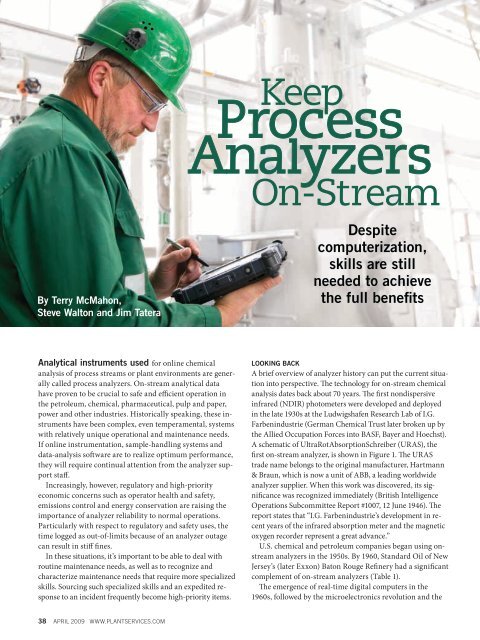

By Terry McMahon,<br />

Steve Walton and Jim Tatera<br />

Despite<br />

computerization,<br />

skills are still<br />

needed to achieve<br />

the full benefits<br />

Analytical instruments used for online chemical<br />

analysis of process streams or plant environments are generally<br />

called process analyzers. On-stream analytical data<br />

have proven to be crucial to safe and efficient operation in<br />

the petroleum, chemical, pharmaceutical, pulp and paper,<br />

power and other industries. Historically speaking, these instruments<br />

have been complex, even temperamental, systems<br />

with relatively unique operational and maintenance needs.<br />

If online instrumentation, sample-handling systems and<br />

data-analysis software are to realize optimum performance,<br />

they will require continual attention from the analyzer support<br />

staff.<br />

Increasingly, however, regulatory and high-priority<br />

economic concerns such as operator health and safety,<br />

emissions control and energy conservation are raising the<br />

importance of analyzer reliability to normal operations.<br />

Particularly with respect to regulatory and safety uses, the<br />

time logged as out-of-limits because of an analyzer outage<br />

can result in stiff fines.<br />

In these situations, it’s important to be able to deal with<br />

routine maintenance needs, as well as to recognize and<br />

characterize maintenance needs that require more specialized<br />

skills. Sourcing such specialized skills and an expedited response<br />

to an incident frequently become high-priority items.<br />

Looking back<br />

A brief overview of analyzer history can put the current situation<br />

into perspective. The technology for on-stream chemical<br />

analysis dates back about 70 years. The first nondispersive<br />

infrared (NDIR) photometers were developed and deployed<br />

in the late 1930s at the Ludwigshafen Research Lab of I.G.<br />

Farbenindustrie (German Chemical Trust later broken up by<br />

the Allied Occupation Forces into BASF, Bayer and Hoechst).<br />

A schematic of UltraRotAbsorptionSchreiber (URAS), the<br />

first on-stream analyzer, is shown in Figure 1. The URAS<br />

trade name belongs to the original manufacturer, Hartmann<br />

& Braun, which is now a unit of ABB, a leading worldwide<br />

analyzer supplier. When this work was discovered, its significance<br />

was recognized immediately (British Intelligence<br />

Operations Subcommittee Report #1007, 12 June 1946). The<br />

report states that “I.G. Farbenindustrie’s development in recent<br />

years of the infrared absorption meter and the magnetic<br />

oxygen recorder represent a great advance.”<br />

U.S. chemical and petroleum companies began using onstream<br />

analyzers in the 1950s. By 1960, Standard Oil of New<br />

Jersey’s (later Exxon) Baton Rouge Refinery had a significant<br />

complement of on-stream analyzers (Table 1).<br />

The emergence of real-time digital computers in the<br />

1960s, followed by the microelectronics revolution and the<br />

38 APRIL 2009 www.PLANTSERVICES.com