Perkins Motor Operation and Maintenance Manual (English) - REED

Perkins Motor Operation and Maintenance Manual (English) - REED

Perkins Motor Operation and Maintenance Manual (English) - REED

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SEBU8325-01 59<br />

<strong>Maintenance</strong> Section<br />

Crankcase Breather (Canister) - Replace<br />

1. Slowly loosen the cooling system filler cap in<br />

order to relieve the pressure. Remove the cooling<br />

system filler cap.<br />

Note: Always discard drained fluids according to<br />

local regulations.<br />

2. If necessary, drain some coolant from the cooling<br />

system into a suitable container in order to allow<br />

space for the extraSCA.<br />

3. Add the correct amount of SCA. Refer to the<br />

<strong>Operation</strong> <strong>and</strong> <strong>Maintenance</strong> <strong>Manual</strong>, “Refill<br />

Capacities <strong>and</strong> Recommendations” for more<br />

information on SCA requirements.<br />

4. Clean the cooling system filler cap <strong>and</strong> inspect the<br />

gasket. If the gasket is damaged, discard the old<br />

filler cap <strong>and</strong> install a new filler cap. If the gasket<br />

is not damaged, use a suitable pressurizing pump<br />

in order to pressure test the filler cap. The correct<br />

pressure is stamped on the face of the filler cap. If<br />

the filler cap does not retain the correct pressure,<br />

install a new filler cap.<br />

i02690442<br />

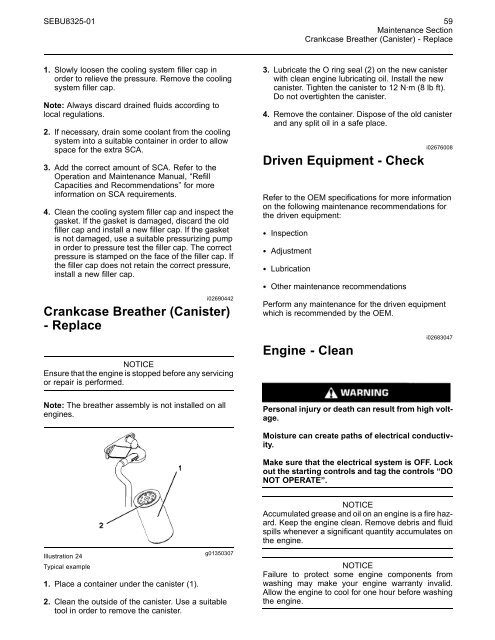

Crankcase Breather (Canister)<br />

- Replace<br />

NOTICE<br />

Ensure that the engine is stopped before any servicing<br />

or repair is performed.<br />

3. Lubricate the O ring seal (2) on the new canister<br />

with clean engine lubricating oil. Install the new<br />

canister. Tighten the canister to 12 N·m (8 lb ft).<br />

Do not overtighten the canister.<br />

4. Remove the container. Dispose of the old canister<br />

<strong>and</strong> any split oil in a safe place.<br />

Driven Equipment - Check<br />

i02676008<br />

Refer to the OEM specifications for more information<br />

on the following maintenance recommendations for<br />

thedrivenequipment:<br />

• Inspection<br />

• Adjustment<br />

• Lubrication<br />

• Other maintenance recommendations<br />

Perform any maintenance for the driven equipment<br />

which is recommended by the OEM.<br />

Engine - Clean<br />

i02683047<br />

Note: The breather assembly is not installed on all<br />

engines.<br />

Personal injury or death can result from high voltage.<br />

Moisture can create paths of electrical conductivity.<br />

Make sure that the electrical system is OFF. Lock<br />

out the starting controls <strong>and</strong> tag the controls “DO<br />

NOT OPERATE”.<br />

NOTICE<br />

Accumulatedgrease<strong>and</strong>oilonanengineisafire hazard.<br />

Keep the engine clean. Remove debris <strong>and</strong> fluid<br />

spills whenever a significant quantity accumulates on<br />

the engine.<br />

Illustration 24<br />

Typical example<br />

1. Place a container under the canister (1).<br />

g01350307<br />

2. Clean the outside of the canister. Use a suitable<br />

tool in order to remove the canister.<br />

NOTICE<br />

Failure to protect some engine components from<br />

washing may make your engine warranty invalid.<br />

Allow the engine to cool for one hour before washing<br />

the engine.