Perkins Motor Operation and Maintenance Manual (English) - REED

Perkins Motor Operation and Maintenance Manual (English) - REED

Perkins Motor Operation and Maintenance Manual (English) - REED

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

66 SEBU8325-01<br />

<strong>Maintenance</strong> Section<br />

Engine Valve Lash - Inspect/Adjust<br />

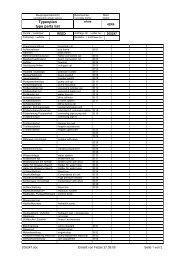

Illustration 34<br />

(Y) “MIN” mark. (X) “MAX” mark.<br />

g01165836<br />

Illustration 33<br />

Typical example<br />

Fill the Engine Crankcase<br />

g02659217<br />

1. Remove the oil filler cap. Refer to the <strong>Operation</strong><br />

<strong>and</strong> <strong>Maintenance</strong> <strong>Manual</strong> for more information on<br />

lubricant specifications. Fill the crankcase with the<br />

proper amount of oil. Refer to the <strong>Operation</strong> <strong>and</strong><br />

<strong>Maintenance</strong> <strong>Manual</strong> for more information on refill<br />

capacities.<br />

NOTICE<br />

If equipped with an auxiliary oil filter system or a remote<br />

oil filter system, follow the OEM or filter manufacturer's<br />

recommendations. Under filling or overfilling<br />

the crankcase with oil can cause engine damage.<br />

NOTICE<br />

To prevent crankshaft bearing damage, crank the engine<br />

with the fuel OFF. This will fill the oil filters before<br />

starting the engine. Do not crank the engine for more<br />

than 30 seconds.<br />

2. Start the engine <strong>and</strong> run the engine at “LOW<br />

IDLE” for 2 minutes. Perform this procedure in<br />

order to ensure that the lubrication system has<br />

oil <strong>and</strong> that the oil filters are filled. Inspect the oil<br />

filter for oil leaks.<br />

3. Stop the engine <strong>and</strong> allow the oil to drain back to<br />

the sump for a minimum of 10 minutes.<br />

4. Remove the oil level gauge in order to check the<br />

oil level. Maintain the oil level between the “MIN”<br />

<strong>and</strong> “MAX” marks on the engine oil dipstick.<br />

Engine Valve Lash -<br />

Inspect/Adjust<br />

i02171102<br />

This maintenance is recommended by <strong>Perkins</strong> as<br />

part of a lubrication <strong>and</strong> preventive maintenance<br />

schedule in order to help provide maximum engine<br />

life.<br />

NOTICE<br />

Only qualified service personel should perform this<br />

maintenance. Refer to the Service <strong>Manual</strong> or your authorized<br />

<strong>Perkins</strong> dealer or your <strong>Perkins</strong> distributor for<br />

the complete valve lash adjustment procedure.<br />

<strong>Operation</strong> of <strong>Perkins</strong> engines with incorrect valve lash<br />

can reduce engine efficiency, <strong>and</strong> also reduce engine<br />

component life.<br />

Ensure that the engine can not be started while<br />

this maintenance is being performed. To help prevent<br />

possible injury, do not use the starting motor<br />

to turn the flywheel.<br />

Hot engine components can cause burns. Allow<br />

additional time for the engine to cool before measuring/adjusting<br />

valve lash clearance.<br />

Ensure that the engine is stopped before measuring<br />

the valve lash. The engine valve lash can be<br />

inspected <strong>and</strong> adjusted when the temperature of the<br />

engine is hot or cold.