Perkins Motor Operation and Maintenance Manual (English) - REED

Perkins Motor Operation and Maintenance Manual (English) - REED

Perkins Motor Operation and Maintenance Manual (English) - REED

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SEBU8325-01 67<br />

<strong>Maintenance</strong> Section<br />

Fuel Injector - Test/Change<br />

Refer to Systems <strong>Operation</strong>/Testing <strong>and</strong> Adjusting,<br />

“Engine Valve Lash - Inspect/Adjust” for more<br />

information.<br />

i02682385<br />

Fuel Injector - Test/Change<br />

The fuel injectors should not be cleaned as cleaning<br />

with incorrect tools can damage the nozzle. The fuel<br />

injectors should be renewed only if a fault with the<br />

fuel injectors occurs. Some of the problems that may<br />

indicate that new fuel injectors are needed are listed<br />

below:<br />

• The engine will not start or the engine is difficult<br />

to start.<br />

• Not enough power<br />

Fuel leaked or spilled onto hot surfaces or electrical<br />

components can cause a fire.<br />

NOTICE<br />

Do not allow dirt to enter the fuel system. Thoroughly<br />

clean the area around a fuel system component that<br />

will be disconnected. Fit a suitable cover over disconnected<br />

fuel system component.<br />

NOTICE<br />

If a fuel injector is suspected of operating outside of<br />

normal parameters it should be removed by a qualified<br />

technician. The suspect fuel injector should be taken<br />

to an authorised agent for inspection.<br />

• Theenginemisfires or the engine runs erratically.<br />

• High fuel consumption<br />

• Black exhaust smoke<br />

• The engine knocks or there is vibration in the<br />

engine.<br />

• Excessive engine temperature<br />

Removal <strong>and</strong> Installation of the<br />

Fuel Injectors<br />

Work carefully around an engine that is running.<br />

Engine parts that are hot, or parts that are moving,<br />

can cause personal injury.<br />

Make sure that you wear eye protection at all<br />

times during testing. When fuel injection nozzles<br />

are tested, test fluids travel through the orifices<br />

of the nozzle tip with high pressure. Under this<br />

amount of pressure, the test fluid can pierce the<br />

skin <strong>and</strong> cause serious injury to the operator.<br />

Always keep the tip of the fuel injection nozzle<br />

pointed away from the operator <strong>and</strong> into the fuel<br />

collector <strong>and</strong> extension.<br />

NOTICE<br />

If your skin comes into contact with high pressure fuel,<br />

obtain medical assistence immediately.<br />

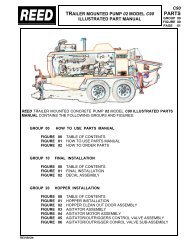

Illustration 35<br />

Typical fuel Injector<br />

g01347499<br />

Operate the engine at a fast idle speed in order to<br />

identify the faulty fuel injector. Individually loosen <strong>and</strong><br />

tighten the union nut for the high pressure pipe to<br />

each fuel injector. Do not loosen the union nut more<br />

than half a turn. There will be little effect on the engine<br />

speed when the union nut to the faulty fuel injection<br />

nozzle is loosened. Refer to the Disassembly <strong>and</strong><br />

Assembly <strong>Manual</strong> for more information. Consult your<br />

authorized <strong>Perkins</strong> dealer or your <strong>Perkins</strong> distributor<br />

for assistance.