You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

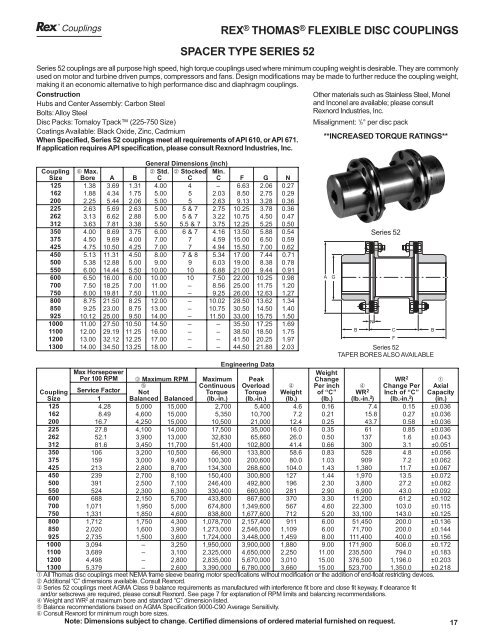

<strong>Couplings</strong><br />

REX ® THOMAS ® FLEXIBLE DISC COUPLINGS<br />

SPACER TYPE SERIES 52<br />

Series 52 couplings are all purpose high speed, high torque couplings used where minimum coupling weight is desirable. They are commonly<br />

used on motor and turbine driven pumps, compressors and fans. Design modifications may be made to further reduce the coupling weight,<br />

making it an economic alternative to high performance disc and diaphragm couplings.<br />

Construction<br />

Hubs and Center Assembly: Carbon Steel<br />

Bolts: Alloy Steel<br />

Disc Packs: Tomaloy Tpack (225-750 Size)<br />

Coatings Available: Black Oxide, Zinc, Cadmium<br />

When Specified, Series 52 couplings meet all requirements of API 610, or API 671.<br />

If application requires API specification, please consult Rexnord Industries, Inc.<br />

General Dimensions (inch)<br />

Coupling ➅ Max.<br />

➁ Std.<br />

➁ Stocked<br />

Min.<br />

Size Bore<br />

A B C C C F G N<br />

125<br />

1.38<br />

3.69<br />

1.31<br />

4.00<br />

4 – 6.63<br />

2.06<br />

0.27<br />

162<br />

1.88<br />

4.34<br />

1.75<br />

5.00<br />

5 2.03<br />

8.50<br />

2.75<br />

0.29<br />

200<br />

2.25<br />

5.44<br />

2.06<br />

5.00<br />

5 2.63<br />

9.13<br />

3.28<br />

0.36<br />

225<br />

2.63<br />

5.69<br />

2.63<br />

5.00<br />

5 & 7 2.75<br />

10.25<br />

3.78<br />

0.36<br />

262<br />

3.13<br />

6.62<br />

2.88<br />

5.00<br />

5 & 7 3.22<br />

10.75<br />

4.50<br />

0.47<br />

312<br />

3.63<br />

7.81<br />

3.38<br />

5.50<br />

5.5<br />

& 7 3.75<br />

12.25<br />

5.25<br />

0.50<br />

350<br />

4.00<br />

8.69<br />

3.75<br />

6.00<br />

6 & 7 4.16<br />

13.50<br />

5.88<br />

0.54<br />

375<br />

4.50<br />

9.69<br />

4.00<br />

7.00<br />

7 4.59<br />

15.00<br />

6.50<br />

0.59<br />

425<br />

4.75<br />

10.50<br />

4.25<br />

7.00<br />

7 4.94<br />

15.50<br />

7.00<br />

0.62<br />

450<br />

5.13<br />

11.31<br />

4.50<br />

8.00<br />

7 & 8 5.34<br />

17.00<br />

7.44<br />

0.71<br />

500<br />

5.38<br />

12.88<br />

5.00<br />

9.00<br />

9 6.03<br />

19.00<br />

8.38<br />

0.78<br />

550<br />

6.00<br />

14.44<br />

5.50<br />

10.00<br />

10<br />

6.88<br />

21.00<br />

9.44<br />

0.91<br />

600<br />

6.50<br />

16.00<br />

6.00<br />

10.00<br />

10<br />

7.50<br />

22.00<br />

10.25<br />

0.98<br />

700<br />

7.50<br />

18.25<br />

7.00<br />

11.00<br />

– 8.56<br />

25.00<br />

11.75<br />

1.20<br />

750<br />

8.00<br />

19.81<br />

7.50<br />

11.00<br />

– 9.25<br />

26.00<br />

12.63<br />

1.27<br />

800<br />

8.75<br />

21.50<br />

8.25<br />

12.00<br />

– 10.02<br />

28.50<br />

13.62<br />

1.34<br />

850<br />

9.25<br />

23.00<br />

8.75<br />

13.00<br />

– 10.75<br />

30.50<br />

14.50<br />

1.40<br />

925<br />

10.12<br />

25.00<br />

9.50<br />

14.00<br />

– 11.50<br />

33.00<br />

15.75<br />

1.50<br />

1000<br />

11.00<br />

27.50<br />

10.50<br />

14.50<br />

– – 35.50<br />

17.25<br />

1.69<br />

1100<br />

12.00<br />

29.19<br />

11.25<br />

16.00<br />

– – 38.50<br />

18.50<br />

1.75<br />

1200<br />

13.00<br />

32.12<br />

12.25<br />

17.00<br />

– – 41.50<br />

20.25<br />

1.97<br />

1300<br />

14.00<br />

34.50<br />

13.25<br />

18.00<br />

– – 44.50<br />

21.88<br />

2.03<br />

Other materials such as Stainless Steel, Monel<br />

and Inconel are available; please consult<br />

Rexnord Industries, Inc.<br />

Misalignment: 1 /3° per disc pack<br />

**INCREASED TORQUE RATINGS**<br />

Series 52<br />

Engineering Data<br />

Max Horsepower<br />

Weight<br />

Per<br />

100 RPM ➂ Maximum<br />

RPM<br />

Maximum<br />

Peak<br />

Change<br />

WR<br />

2 ➀<br />

➄ Continuous Overload ➃ Per inch ➃ Change Per<br />

Axial<br />

Coupling Service Factor Not<br />

Torque Torque W eight<br />

of “C” WR<br />

2<br />

Inch of “C” Capacity<br />

Size<br />

1 Balanced<br />

Balanced<br />

(lb.-in.) (lb.-in.) ( lb. ) (lb.) ( lb.-in. 2<br />

) ( lb.-in. 2<br />

) (in.)<br />

125<br />

4.28<br />

5,000<br />

15,000<br />

2,700<br />

5,400<br />

4.<br />

6 0.16<br />

7.<br />

4 0.15<br />

±0.036<br />

162<br />

8.49<br />

4,600<br />

15,000<br />

5,350<br />

10,700<br />

7.<br />

2 0.21<br />

15.<br />

8 0.27<br />

±0.036<br />

200<br />

16.<br />

7 4,250<br />

15,000<br />

10,500<br />

21,000<br />

12.<br />

4 0.25<br />

43.<br />

7 0.58<br />

±0.036<br />

225<br />

27.<br />

8 4,100<br />

14,000<br />

17,500<br />

35,000<br />

16.<br />

0 0.35<br />

61<br />

0.85<br />

±0.036<br />

262<br />

52.<br />

1 3,900<br />

13,000<br />

32,830<br />

65,660<br />

26.<br />

0 0.50<br />

137<br />

1.<br />

6 ±0.043<br />

312<br />

81.<br />

6 3,450<br />

11,700<br />

51,400<br />

102,800<br />

41.<br />

4 0.66<br />

300<br />

3.<br />

1 ±0.051<br />

350<br />

106<br />

3,200<br />

10,500<br />

66,900<br />

133,800<br />

58.<br />

6 0.83<br />

528<br />

4.<br />

8 ±0.056<br />

375<br />

159<br />

3,000<br />

9,400<br />

100,300<br />

200,600<br />

80.<br />

0 1.03<br />

909<br />

7.<br />

2 ±0.062<br />

425<br />

213<br />

2,800<br />

8,700<br />

134,300<br />

268,600<br />

104.<br />

0 1.43<br />

1,380<br />

11.<br />

7 ±0.067<br />

450<br />

239<br />

2,700<br />

8,100<br />

150,400<br />

300,800<br />

127<br />

1.44<br />

1,970<br />

13.<br />

5 ±0.072<br />

500<br />

391<br />

2,500<br />

7,100<br />

246,400<br />

492,800<br />

196<br />

2.30<br />

3,800<br />

27.<br />

2 ±0.082<br />

550<br />

524<br />

2,300<br />

6,300<br />

330,400<br />

660,800<br />

281<br />

2.90<br />

6,900<br />

43.<br />

0 ±0.092<br />

600<br />

688<br />

2,150<br />

5,700<br />

433,800<br />

867,600<br />

370<br />

3.30<br />

11,200<br />

61.<br />

2 ±0.102<br />

700<br />

1,071<br />

1,950<br />

5,000<br />

674,800<br />

1,349,600<br />

567<br />

4.60<br />

22,300<br />

103.<br />

0 ±0.115<br />

750<br />

1,331<br />

1,850<br />

4,600<br />

838,800<br />

1,677,600<br />

712<br />

5.20<br />

33,100<br />

143.<br />

0 ±0.125<br />

800<br />

1,712<br />

1,750<br />

4,300<br />

1,078,700<br />

2,157,400<br />

911<br />

6.00<br />

51,450<br />

200.<br />

0 ±0.136<br />

850<br />

2,020<br />

1,600<br />

3,900<br />

1,273,000<br />

2,546,000<br />

1,109<br />

6.00<br />

71,700<br />

200.<br />

0 ±0.144<br />

925<br />

2,735<br />

1,500<br />

3,600<br />

1,724,000<br />

3,448,000<br />

1,459<br />

8.00<br />

111,40<br />

0 400.<br />

0 ±0.156<br />

1000<br />

3 ,094<br />

– 3,250<br />

1,950,000<br />

3,900,000<br />

1,880<br />

9.00<br />

171,900<br />

506.<br />

0 ±0.172<br />

1100<br />

3 ,689<br />

– 3,100<br />

2,325,000<br />

4,650,000<br />

2,250<br />

11.00<br />

235,500<br />

794.<br />

0 ±0.183<br />

1200<br />

4 ,498<br />

– 2,800<br />

2,835,000<br />

5,670,000<br />

3,010<br />

15.00<br />

376,500<br />

1,196.<br />

0 ±0.203<br />

1300<br />

5 ,379<br />

– 2,600<br />

3,390,000<br />

6,780,000<br />

3,660<br />

15.00<br />

523,700<br />

1,350.<br />

0 ±0.218<br />

➀ All Thomas disc couplings meet NEMA frame sleeve bearing motor specifications without modification or the addition of end-float restricting devices .<br />

➁ Additional “C” dimensions available. Consult Rexnord .<br />

➂ Series 52 couplings meet AGMA Class 9 balance requirements as manufactured with interference fit bore and close fit keyway. If clearance fit<br />

and/or<br />

setscrews are required, please consult Rexnord. Seep age 7for<br />

explanation of RPM limits and balancing recommendations .<br />

➃ Weight<br />

and WR2 at maximum bore and standard “C” dimension listed .<br />

➄ Balance recommendations based on AGMA Specification 9000-C90 Average Sensitivity .<br />

➅ Consult Rexnord for minimum rough bore sizes .<br />

Note: Dimensions subject to change. Certified dimensions of ordered material furnished on request. 17<br />

A<br />

G<br />

B<br />

N<br />

Series 52<br />

TAPER BORES ALSO AVAILABLE<br />

C<br />

F<br />

B