You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Couplings</strong><br />

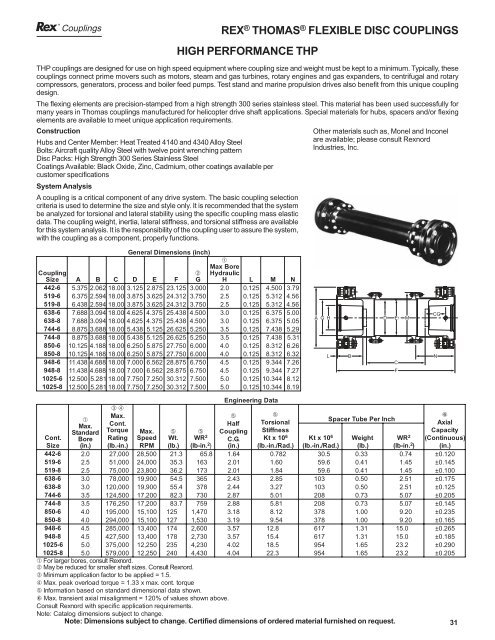

REX ® THOMAS ® FLEXIBLE DISC COUPLINGS<br />

HIGH PERFORMANCE THP<br />

THP couplings are designed for use on high speed equipment where coupling size and weight must be kept to a minimum. Typically, these<br />

couplings connect prime movers such as motors, steam and gas turbines, rotary engines and gas expanders, to centrifugal and rotary<br />

compressors, generators, process and boiler feed pumps. Test stand and marine propulsion drives also benefit from this unique coupling<br />

design.<br />

The flexing elements are precision-stamped from a high strength 300 series stainless steel. This material has been used successfully for<br />

many years in Thomas couplings manufactured for helicopter drive shaft applications. Special materials for hubs, spacers and/or flexing<br />

elements are available to meet unique application requirements.<br />

Construction<br />

Hubs and Center Member: Heat Treated 4140 and 4340 Alloy Steel<br />

Bolts: Aircraft quality Alloy Steel with twelve point wrenching pattern<br />

Disc Packs: High Strength 300 Series Stainless Steel<br />

Coatings Available: Black Oxide, Zinc, Cadmium, other coatings available per<br />

customer specifications<br />

System Analysis<br />

A coupling is a critical component of any drive system. The basic coupling selection<br />

criteria is used to determine the size and style only. It is recommended that the system<br />

be analyzed for torsional and lateral stability using the specific coupling mass elastic<br />

data. The coupling weight, inertia, lateral stiffness, and torsional stiffness are available<br />

for this system analysis. It is the responsibility of the coupling user to assure the system,<br />

with the coupling as a component, properly functions.<br />

General Dimensions (inch)<br />

Other materials such as, Monel and Inconel<br />

are available; please consult Rexnord<br />

Industries, Inc.<br />

Coupling<br />

Size<br />

A B C D E F<br />

➀<br />

Max<br />

Bore<br />

➁ Hydraulic<br />

G H L M N<br />

442-6<br />

5.375<br />

2.062<br />

18.00<br />

3.125<br />

2.875<br />

23.125<br />

3.000<br />

2.<br />

0 0.125<br />

4.500<br />

3.79<br />

519-6<br />

6.375<br />

2.594<br />

18.00<br />

3.875<br />

3.625<br />

24.312<br />

3.750<br />

2.<br />

5 0.125<br />

5.312<br />

4.56<br />

519-8<br />

6.438<br />

2.594<br />

18.00<br />

3.875<br />

3.625<br />

24.312<br />

3.750<br />

2.<br />

5 0.125<br />

5.312<br />

4.56<br />

638-6<br />

7.688<br />

3.094<br />

18.00<br />

4.625<br />

4.375<br />

25.438<br />

4.500<br />

3.<br />

0 0.125<br />

6.375<br />

5.00<br />

638-8<br />

7.688<br />

3.094<br />

18.00<br />

4.625<br />

4.375<br />

25.438<br />

4.500<br />

3.<br />

0 0.125<br />

6.375<br />

5.05<br />

744-6<br />

8.875<br />

3.688<br />

18.00<br />

5.438<br />

5.125<br />

26.625<br />

5.250<br />

3.<br />

5 0.125<br />

7.438<br />

5.29<br />

744-8<br />

8.875<br />

3.688<br />

18.00<br />

5.438<br />

5.125<br />

26.625<br />

5.250<br />

3.<br />

5 0.125<br />

7.438<br />

5.31<br />

850-6<br />

10.125<br />

4.188<br />

18.00<br />

6.250<br />

5.875<br />

27.750<br />

6.000<br />

4.<br />

0 0.125<br />

8.312<br />

6.26<br />

850-8<br />

10.125<br />

4.188<br />

18.00<br />

6.250<br />

5.875<br />

27.750<br />

6.000<br />

4.<br />

0 0.125<br />

8.312<br />

6.32<br />

948-6<br />

11.43<br />

8 4.688<br />

18.00<br />

7.000<br />

6.562<br />

28.875<br />

6.750<br />

4.<br />

5 0.125<br />

9.344<br />

7.26<br />

948-8<br />

11.43<br />

8 4.688<br />

18.00<br />

7.000<br />

6.562<br />

28.875<br />

6.750<br />

4.<br />

5 0.125<br />

9.344<br />

7.27<br />

1025-6<br />

12.500<br />

5.28118.00<br />

7.750<br />

7.250<br />

30.312<br />

7.500<br />

5.<br />

0 0.125<br />

10.344<br />

8.12<br />

1025-8<br />

12.500<br />

5.28118.00<br />

7.750<br />

7.250<br />

30.312<br />

7.500<br />

5.<br />

0 0.125<br />

10.344<br />

8.19<br />

A G H<br />

L<br />

B<br />

D<br />

E<br />

C<br />

F<br />

M<br />

CG<br />

N<br />

Engineering Data<br />

Max.<br />

➄<br />

➄<br />

6<br />

➀<br />

Max.<br />

Cont.<br />

Half Torsional<br />

Spacer Tube Per Inch<br />

Axial<br />

Standard<br />

Torque Max.<br />

➄ ➄ Coupling Stiffness<br />

Capacity<br />

Cont. B ore Rating Speed<br />

W t.<br />

WR<br />

2<br />

C .G. Kt<br />

x 106<br />

Kt<br />

x 106<br />

Weight WR<br />

2 (Continuous)<br />

Size ( in. ) ( l b.-in.<br />

) RPM<br />

(lb.)<br />

( lb-in.<br />

) ( in. ) (lb.-in./Rad.) (lb.-in./Rad.) (lb.) ( lb-in.<br />

) (in.)<br />

➂➃<br />

442-6<br />

2.<br />

0 27,000<br />

28,500<br />

21.<br />

3 65.<br />

8 1.64<br />

0.782<br />

30.<br />

5 0.33<br />

0.74<br />

±0.120<br />

519-6<br />

2.<br />

5 51,000<br />

24,000<br />

35.<br />

3 163<br />

2.01<br />

1.60<br />

59.<br />

6 0.41<br />

1.45<br />

±0.145<br />

519-8<br />

2.<br />

5 75,000<br />

23,800<br />

36.<br />

2 173<br />

2.01<br />

1.84<br />

59.<br />

6 0.41<br />

1.45<br />

±0.100<br />

638-6<br />

3.<br />

0 78,000<br />

19,900<br />

54.<br />

5 365<br />

2.43<br />

2.85<br />

103<br />

0.50<br />

2.51<br />

±0.175<br />

638-8<br />

3.<br />

0 120,000<br />

19,900<br />

55.<br />

4 378<br />

2.44<br />

3.27<br />

103<br />

0.50<br />

2.51<br />

±0.125<br />

744-6<br />

3.<br />

5 124,500<br />

17,200<br />

82.<br />

3 730<br />

2.87<br />

5.01<br />

208<br />

0.73<br />

5.07<br />

±0.205<br />

744-8<br />

3.<br />

5 176,250<br />

17,200<br />

83.<br />

7 759<br />

2.88<br />

5.81<br />

208<br />

0.73<br />

5.07<br />

±0.145<br />

850-6<br />

4.<br />

0 195,000<br />

15,100<br />

125<br />

1, 470<br />

3.18<br />

8.12<br />

378<br />

1.00<br />

9.20<br />

±0.235<br />

850-8<br />

4.<br />

0 294,000<br />

15,100<br />

127<br />

1, 530<br />

3.19<br />

9.54<br />

378<br />

1.00<br />

9.20<br />

±0.165<br />

948-6<br />

4.<br />

5 285,000<br />

13,400<br />

174<br />

2, 600<br />

3.57<br />

12.<br />

8<br />

617<br />

1.31<br />

15.<br />

0 ±0.265<br />

948-8<br />

4.<br />

5 427,500<br />

13,400<br />

178<br />

2, 730<br />

3.57<br />

15.<br />

4<br />

617<br />

1.31<br />

15.<br />

0 ±0.185<br />

1025-6<br />

5.<br />

0 375,000<br />

12,250<br />

235<br />

4, 230<br />

4.02<br />

18.<br />

5<br />

954<br />

1.65<br />

23.<br />

2 ±0.290<br />

1025-8<br />

5.<br />

0 579,000<br />

12,250<br />

240<br />

4, 430<br />

4.04<br />

22.<br />

3<br />

954<br />

1.65<br />

23.<br />

2 ±0.205<br />

➀ For larger bores, consult Rexnord .<br />

➁ May be reduced for smaller shaft sizes. Consult Rexnord .<br />

➂ Minimum application factor to be applied = 1.5.<br />

➃ Max. peak overload torque = 1.33 x max. cont. torque<br />

➄ Information based on standard dimensional data shown.<br />

6 Max. transient axial misalignment = 120% of values shown above.<br />

Consult Rexnord with specific application requirements.<br />

Note: Catalog dimensions subject to change.<br />

Note: Dimensions subject to change. Certified dimensions of ordered material furnished on request. 31