Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Couplings</strong><br />

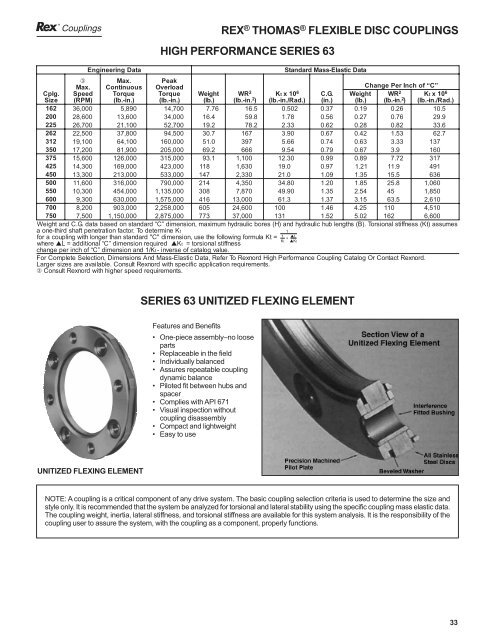

REX ® THOMAS ® FLEXIBLE DISC COUPLINGS<br />

HIGH PERFORMANCE SERIES 63<br />

Engineering<br />

Data<br />

Standard Mass-Elastic Data<br />

➂ Max. Peak<br />

Max. Continuous Overload<br />

Change Per Inch of “C”<br />

Cplg.<br />

Weight WR<br />

2 Kt x 106<br />

C.G. Weight WR<br />

2 Kt x 106<br />

Size<br />

(lb.) ( lb.-in.<br />

2<br />

) (lb.-in./Rad.) (in.) (lb.) ( lb.-in . 2<br />

) (lb.-in./Rad.)<br />

Speed<br />

(RPM)<br />

Torque<br />

(lb.-in.)<br />

Torque<br />

(lb.-in.)<br />

162<br />

36,000<br />

5,890<br />

14,700<br />

7.76<br />

16.<br />

5 0.502<br />

0.37<br />

0.19<br />

0.26<br />

10. 5<br />

200<br />

28,600<br />

13,600<br />

34,000<br />

16.<br />

4 59.<br />

8 1.78<br />

0.56<br />

0.27<br />

0.76<br />

29. 9<br />

225<br />

26,700<br />

21,100<br />

52,700<br />

19.<br />

2 78.<br />

2 2.33<br />

0.62<br />

0.28<br />

0.82<br />

33. 6<br />

262<br />

22,500<br />

37,800<br />

94,500<br />

30.<br />

7 167<br />

3.90<br />

0.67<br />

0.42<br />

1.53<br />

62. 7<br />

312<br />

19,100<br />

64,100<br />

160,000<br />

51.<br />

0 397<br />

5.66<br />

0.74<br />

0.63<br />

3.33<br />

137<br />

350<br />

17,200<br />

81,900<br />

205,000<br />

69.<br />

2 666<br />

9.54<br />

0.79<br />

0.67<br />

3.<br />

9 160<br />

375<br />

15,600<br />

126,000<br />

315,000<br />

93.<br />

1 1,100<br />

12.30<br />

0.99<br />

0.89<br />

7.72<br />

317<br />

425<br />

14,300<br />

169,000<br />

423,000<br />

118<br />

1,630<br />

19.<br />

0 0.97<br />

1.21<br />

11.<br />

9 491<br />

450<br />

13,300<br />

213,000<br />

533,000<br />

147<br />

2,330<br />

21.<br />

0 1.09<br />

1.35<br />

15.<br />

5 636<br />

500<br />

11,600<br />

316,000<br />

790,000<br />

214<br />

4,350<br />

34.80<br />

1.20<br />

1.85<br />

25.<br />

8 1,060<br />

550<br />

10,300<br />

454,000<br />

1,135,000<br />

308<br />

7,870<br />

49.90<br />

1.35<br />

2.54<br />

45<br />

1,850<br />

600<br />

9,300<br />

630,000<br />

1,575,000<br />

416<br />

13,000<br />

61.<br />

3 1.37<br />

3.15<br />

63.<br />

5 2,610<br />

700<br />

8,200<br />

903,000<br />

2,258,000<br />

605<br />

24,600<br />

100<br />

1.46<br />

4.25<br />

110<br />

4,510<br />

750<br />

7,500<br />

1,150,000<br />

2,875,000<br />

773<br />

37,000<br />

131<br />

1.52<br />

5.02<br />

162<br />

6,600<br />

Weight and C.G. data based on standard “C” dimension, maximum hydraulic bores (H) and hydraulic hub lengths (B). Torsional stiffness (Kt) assumes<br />

a one-third shaft penetration factor. To determine Kt<br />

1<br />

Larger<br />

sizes are available. Consult Rexnord with specific application requirements.<br />

➂ Consult<br />

Rexnord with higher speed requirements .<br />

for a coupling with longer than standard "C" dimension, use the following formula Kt =<br />

where<br />

▲L = additional “C” dimension required<br />

▲Kt = torsional stiffnes s<br />

1 +<br />

▲L<br />

Kt ▲Kt<br />

change<br />

per inch of “C” dimension and 1/Kt - inverse of catalog value .<br />

For Complete Selection, Dimensions And Mass-Elastic Data, Refer To Rexnord High Performance Coupling Catalog Or Contact Rexnord.<br />

SERIES 63 UNITIZED FLEXING ELEMENT<br />

Features and Benefits<br />

• One-piece assembly–no loose<br />

parts<br />

• Replaceable in the field<br />

• Individually balanced<br />

• Assures repeatable coupling<br />

dynamic balance<br />

• Piloted fit between hubs and<br />

spacer<br />

• Complies with API 671<br />

• Visual inspection without<br />

coupling disassembly<br />

• Compact and lightweight<br />

• Easy to use<br />

UNITIZED FLEXING ELEMENT<br />

NOTE: A coupling is a critical component of any drive system. The basic coupling selection criteria is used to determine the size and<br />

style only. It is recommended that the system be analyzed for torsional and lateral stability using the specific coupling mass elastic data.<br />

The coupling weight, inertia, lateral stiffness, and torsional stiffness are available for this system analysis. It is the responsibility of the<br />

coupling user to assure the system, with the coupling as a component, properly functions.<br />

33