Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

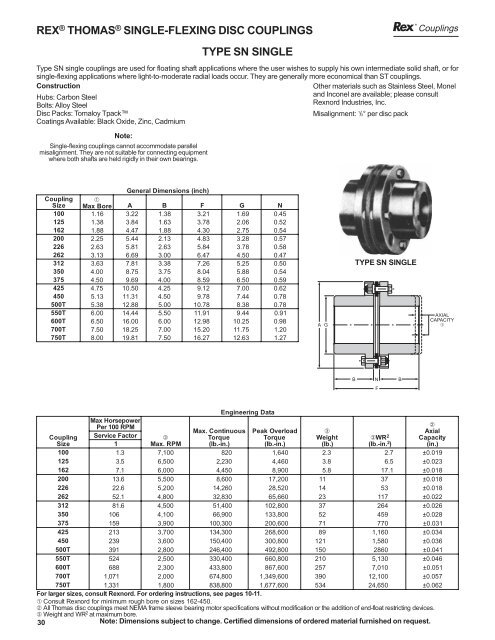

REX ® THOMAS ® SINGLE-FLEXING DISC COUPLINGS<br />

<strong>Couplings</strong><br />

TYPE SN SINGLE<br />

Type SN single couplings are used for floating shaft applications where the user wishes to supply his own intermediate solid shaft, or for<br />

single-flexing applications where light-to-moderate radial loads occur. They are generally more economical than ST couplings.<br />

Construction<br />

Other materials such as Stainless Steel, Monel<br />

Hubs: Carbon Steel<br />

and Inconel are available; please consult<br />

Bolts: Alloy Steel<br />

Rexnord Industries, Inc.<br />

Disc Packs: Tomaloy Tpack<br />

Misalignment: 1 /3° per disc pack<br />

Coatings Available: Black Oxide, Zinc, Cadmium<br />

Note:<br />

Single-flexing couplings cannot accommodate parallel<br />

misalignment. They are not suitable for connecting equipment<br />

where both shafts are held rigidly in their own bearings.<br />

General Dimensions (inch)<br />

Coupling ➀<br />

Size Max<br />

Bore<br />

A B F G N<br />

100<br />

1.16<br />

3.22<br />

1.38<br />

3.21<br />

1.69<br />

0.45<br />

125<br />

1.38<br />

3.84<br />

1.63<br />

3.78<br />

2.06<br />

0.52<br />

162<br />

1.88<br />

4.47<br />

1.88<br />

4.30<br />

2.75<br />

0.54<br />

200<br />

2.25<br />

5.44<br />

2.13<br />

4.83<br />

3.28<br />

0.57<br />

226<br />

2.63<br />

5.81<br />

2.63<br />

5.84<br />

3.78<br />

0.58<br />

262<br />

3.13<br />

6.69<br />

3.00<br />

6.47<br />

4.50<br />

0.47<br />

312<br />

3.63<br />

7.81<br />

3.38<br />

7.26<br />

5.25<br />

0.50<br />

350<br />

4.00<br />

8.75<br />

3.75<br />

8.04<br />

5.88<br />

0.54<br />

375<br />

4.50<br />

9.69<br />

4.00<br />

8.59<br />

6.50<br />

0.59<br />

425<br />

4.75<br />

10.50<br />

4.25<br />

9.12<br />

7.00<br />

0.62<br />

450<br />

5.13<br />

11.31<br />

4.50<br />

9.78<br />

7.44<br />

0.78<br />

500T<br />

5.38<br />

12.88<br />

5.00<br />

10.78<br />

8.38<br />

0.78<br />

550T<br />

6.00<br />

14.44<br />

5.50<br />

11.91<br />

9.44<br />

0.91<br />

600T<br />

6.50<br />

16.00<br />

6.00<br />

12.98<br />

10.25<br />

0.98<br />

700T<br />

7.50<br />

18.25<br />

7.00<br />

15.20<br />

11.75<br />

1.20<br />

750T<br />

8.00<br />

19.81<br />

7.50<br />

16.27<br />

12.63<br />

1.27<br />

A G<br />

TYPE SN SINGLE<br />

AXIAL<br />

CAPACITY<br />

➀<br />

B<br />

N<br />

F<br />

B<br />

Engineering Data<br />

Max Horsepower<br />

Per 100 RPM<br />

➁<br />

Max. Continuous Peak Overload ➂<br />

Axial<br />

Coupling Service Factor ➂<br />

Torque<br />

Torque W eight<br />

➂WR<br />

Capacity<br />

Size<br />

1<br />

Max. RPM (lb.-in.)<br />

(lb.-in.)<br />

(lb.)<br />

( lb.-in. 2<br />

)<br />

(in.)<br />

100<br />

1.<br />

3<br />

7,100<br />

820<br />

1,640<br />

2.<br />

3<br />

2.<br />

7 ±0.019<br />

125<br />

3.<br />

5<br />

6,500<br />

2,230<br />

4,460<br />

3.<br />

8<br />

6.<br />

5 ±0.023<br />

162<br />

7.<br />

1<br />

6,000<br />

4,450<br />

8,900<br />

5.<br />

8<br />

17.<br />

1 ±0.018<br />

200<br />

13.<br />

6<br />

5,500<br />

8,600<br />

17,200<br />

11<br />

37<br />

±0.018<br />

226<br />

22.<br />

6<br />

5,200<br />

14,260<br />

28,520<br />

14<br />

53<br />

±0.018<br />

262<br />

52.<br />

1<br />

4,800<br />

32,830<br />

65,660<br />

23<br />

117<br />

±0.022<br />

312<br />

81.<br />

6<br />

4,500<br />

51,400<br />

102,800<br />

37<br />

264<br />

±0.026<br />

350<br />

106<br />

4,100<br />

66,900<br />

133,800<br />

52<br />

459<br />

±0.028<br />

375<br />

159<br />

3,900<br />

100,300<br />

200,600<br />

71<br />

770<br />

±0.031<br />

425<br />

213<br />

3,700<br />

134,300<br />

268,600<br />

89<br />

1,160<br />

±0.034<br />

450<br />

239<br />

3,600<br />

150,400<br />

300,800<br />

121<br />

1,580<br />

±0.036<br />

500T<br />

391<br />

2,800<br />

246,400<br />

492,800<br />

150<br />

2860<br />

±0.041<br />

550T<br />

524<br />

2,500<br />

330,400<br />

660,800<br />

210<br />

5,130<br />

±0.046<br />

600T<br />

688<br />

2,300<br />

433,800<br />

867,600<br />

257<br />

7,010<br />

±0.051<br />

700T<br />

1,071<br />

2,000<br />

674,800<br />

1,349,600<br />

390<br />

12,100<br />

±0.057<br />

750T<br />

1,331<br />

1,800<br />

838,800<br />

1,677,600<br />

534<br />

24,650<br />

±0.062<br />

For larger sizes, consult Rexnord. For ordering instructions, see pages 10-11.<br />

➀ C onsult Rexnord for minimum rough bore on sizes 162-450.<br />

➁ All Thomas disc couplings meet NEMA frame sleeve bearing motor specifications without modification or the addition of end-float restricting devices .<br />

➂ Weight<br />

and WR2 at maximum bore.<br />

30<br />

Note: Dimensions subject to change. Certified dimensions of ordered material furnished on request.