Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

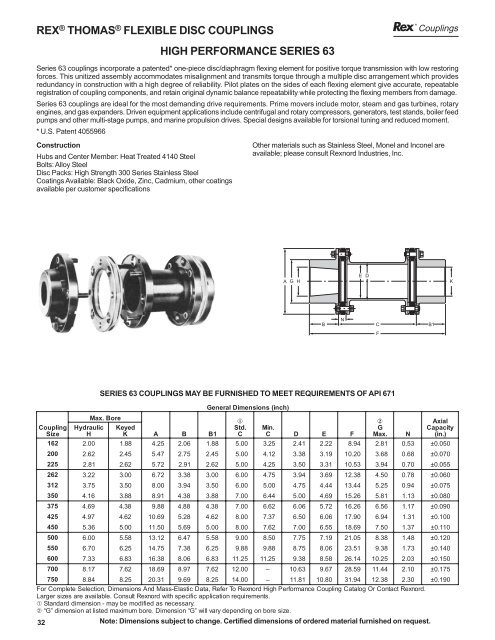

REX ® THOMAS ® FLEXIBLE DISC COUPLINGS<br />

<strong>Couplings</strong><br />

HIGH PERFORMANCE SERIES 63<br />

Series 63 couplings incorporate a patented* one-piece disc/diaphragm flexing element for positive torque transmission with low restoring<br />

forces. This unitized assembly accommodates misalignment and transmits torque through a multiple disc arrangement which provides<br />

redundancy in construction with a high degree of reliability. Pilot plates on the sides of each flexing element give accurate, repeatable<br />

registration of coupling components, and retain original dynamic balance repeatability while protecting the flexing members from damage.<br />

Series 63 couplings are ideal for the most demanding drive requirements. Prime movers include motor, steam and gas turbines, rotary<br />

engines, and gas expanders. Driven equipment applications include centrifugal and rotary compressors, generators, test stands, boiler feed<br />

pumps and other multi-stage pumps, and marine propulsion drives. Special designs available for torsional tuning and reduced moment.<br />

* U.S. Patent 4055966<br />

Construction<br />

Hubs and Center Member: Heat Treated 4140 Steel<br />

Bolts: Alloy Steel<br />

Disc Packs: High Strength 300 Series Stainless Steel<br />

Coatings Available: Black Oxide, Zinc, Cadmium, other coatings<br />

available per customer specifications<br />

Other materials such as Stainless Steel, Monel and Inconel are<br />

available; please consult Rexnord Industries, Inc.<br />

A G H<br />

E<br />

D<br />

K<br />

B<br />

N<br />

C<br />

B1<br />

F<br />

Coupling<br />

Size<br />

62<br />

32<br />

SERIES 63 COUPLINGS MAY BE FURNISHED TO MEET REQUIREMENTS OF API 671<br />

Max. Bore<br />

Hydraulic<br />

H<br />

Keyed<br />

K<br />

A B B1<br />

General Dimensions (inch)<br />

1<br />

Std.<br />

C<br />

Min.<br />

C D E F<br />

2<br />

G<br />

Max.<br />

Note: Dimensions subject to change. Certified dimensions of ordered material furnished on request.<br />

N<br />

Axial<br />

Capacity<br />

(in.)<br />

1 2.00<br />

1.88<br />

4.25<br />

2.06<br />

1.88<br />

5.00<br />

3.25<br />

2.41<br />

2.22<br />

8.94<br />

2.81<br />

0.53<br />

±0.050<br />

200<br />

2.62<br />

2.45<br />

5.47<br />

2.75<br />

2.45<br />

5.00<br />

4.12<br />

3.38<br />

3.19<br />

10.20<br />

3.68<br />

0.68<br />

±0.070<br />

225<br />

2.81<br />

2.62<br />

5.72<br />

2.91<br />

2.62<br />

5.00<br />

4.25<br />

3.50<br />

3.31<br />

10.53<br />

3.94<br />

0.70<br />

±0.055<br />

262<br />

3.22<br />

3.00<br />

6.72<br />

3.38<br />

3.00<br />

6.00<br />

4.75<br />

3.94<br />

3.69<br />

12.38<br />

4.50<br />

0.78<br />

±0.060<br />

312<br />

3.75<br />

3.50<br />

8.00<br />

3.94<br />

3.50<br />

6.00<br />

5.00<br />

4.75<br />

4.44<br />

13.44<br />

5.25<br />

0.94<br />

±0.075<br />

350<br />

4.16<br />

3.88<br />

8.91<br />

4.38<br />

3.88<br />

7.00<br />

6.44<br />

5.00<br />

4.69<br />

15.26<br />

5.81<br />

1.13<br />

±0.080<br />

375<br />

4.69<br />

4.38<br />

9.88<br />

4.88<br />

4.38<br />

7.00<br />

6.62<br />

6.06<br />

5.72<br />

16.26<br />

6.56<br />

1.17<br />

±0.090<br />

425<br />

4.97<br />

4.62<br />

10.69<br />

5.28<br />

4.62<br />

8.00<br />

7.37<br />

6.50<br />

6.06<br />

17.90<br />

6.94<br />

1.31<br />

±0.100<br />

450<br />

5.36<br />

5.00<br />

11.50<br />

5.69<br />

5.00<br />

8.00<br />

7.62<br />

7.00<br />

6.55<br />

18.69<br />

7.50<br />

1.37<br />

±0.110<br />

500<br />

6.00<br />

5.58<br />

13.12<br />

6.47<br />

5.58<br />

9.00<br />

8.50<br />

7.75<br />

7.19<br />

21.05<br />

8.38<br />

1.48<br />

±0.120<br />

550<br />

6.70<br />

6.25<br />

14.75<br />

7.38<br />

6.25<br />

9.88<br />

9.88<br />

8.75<br />

8.06<br />

23.51<br />

9.38<br />

1.73<br />

±0.140<br />

600<br />

7.33<br />

6.83<br />

16.38<br />

8.06<br />

6.83<br />

11.25<br />

11.2<br />

5 9.38<br />

8.58<br />

26.14<br />

10.25<br />

2.03<br />

±0.150<br />

700<br />

8.17<br />

7.62<br />

18.69<br />

8.97<br />

7.62<br />

12.00<br />

– 10.63<br />

9.67<br />

28.59<br />

11.44<br />

2.10<br />

±0.175<br />

750<br />

8.84<br />

8.25<br />

20.31<br />

9.69<br />

8.25<br />

14.00<br />

– 11.81<br />

10.80<br />

31.94<br />

12.38<br />

2.30<br />

±0.190<br />

For Complete Selection, Dimensions And Mass-Elastic Data, Refer To Rexnord High Performance Coupling Catalog Or Contact Rexnord.<br />

Larger sizes are available. Consult Rexnord with specific application requirements.<br />

➀ Standard dimension - may be modified as necessary.<br />

➁ “G” dimension at listed maximum bore. Dimension “G” will vary depending on bore size.