Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

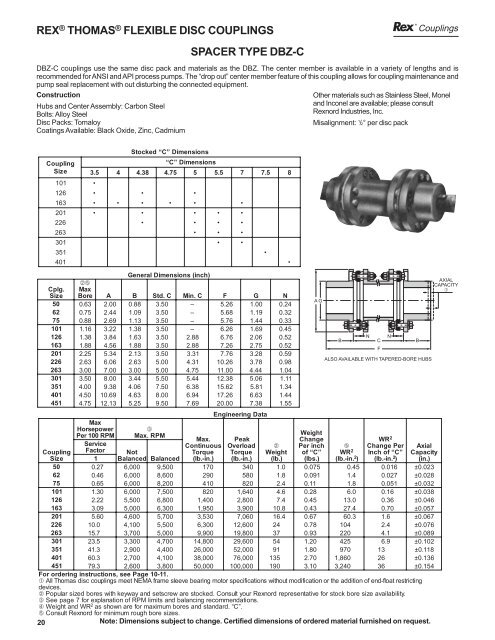

REX ® THOMAS ® FLEXIBLE DISC COUPLINGS<br />

<strong>Couplings</strong><br />

SPACER TYPE DBZ-C<br />

DBZ-C couplings use the same disc pack and materials as the DBZ. The center member is available in a variety of lengths and is<br />

recommended for ANSI and API process pumps. The “drop out” center member feature of this coupling allows for coupling maintenance and<br />

pump seal replacement with out disturbing the connected equipment.<br />

Construction<br />

Hubs and Center Assembly: Carbon Steel<br />

Bolts: Alloy Steel<br />

Disc Packs: Tomaloy<br />

Coatings Available: Black Oxide, Zinc, Cadmium<br />

Other materials such as Stainless Steel, Monel<br />

and Inconel are available; please consult<br />

Rexnord Industries, Inc.<br />

Misalignment: 1 /2° per disc pack<br />

Coupling<br />

Size<br />

101<br />

•<br />

Stocked “C” Dimensions<br />

“C” Dimensions<br />

3.5<br />

4 4.38<br />

4.75<br />

5 5.<br />

5 7 7.<br />

5 8<br />

126<br />

• • •<br />

163<br />

• • • • • •<br />

201<br />

• • • • •<br />

226<br />

• • • •<br />

263<br />

• • •<br />

301<br />

• •<br />

351<br />

•<br />

401<br />

•<br />

General Dimensions (inch)<br />

➁➄<br />

Cplg.<br />

Size<br />

Max<br />

Bore<br />

A B Std.<br />

C Min.<br />

C F G N<br />

50<br />

0.63<br />

2.00<br />

0.88<br />

3 .50<br />

– 5.26<br />

1.00<br />

0.24<br />

62<br />

0.75<br />

2.44<br />

1.09<br />

3 .50<br />

– 5.68<br />

1.19<br />

0.32<br />

75<br />

0.88<br />

2.69<br />

1.13<br />

3 .50<br />

– 5.76<br />

1.44<br />

0.33<br />

101<br />

1.16<br />

3.22<br />

1.38<br />

3 .50<br />

– 6.26<br />

1.69<br />

0.45<br />

126<br />

1.38<br />

3.84<br />

1.63<br />

3.50<br />

2.88<br />

6.76<br />

2.06<br />

0.52<br />

163<br />

1.88<br />

4.56<br />

1.88<br />

3.50<br />

2.88<br />

7.26<br />

2.75<br />

0.52<br />

201<br />

2.25<br />

5.34<br />

2.13<br />

3.50<br />

3.31<br />

7.76<br />

3.28<br />

0.59<br />

226<br />

2.63<br />

6.06<br />

2.63<br />

5.00<br />

4.31<br />

10.26<br />

3.78<br />

0.98<br />

263<br />

3.00<br />

7.00<br />

3.00<br />

5.00<br />

4.75<br />

11.00<br />

4.44<br />

1.04<br />

301<br />

3.50<br />

8.00<br />

3.44<br />

5.50<br />

5.44<br />

12.38<br />

5.06<br />

1.11<br />

351<br />

4.00<br />

9.38<br />

4.06<br />

7.50<br />

6.38<br />

15.62<br />

5.81<br />

1.34<br />

401<br />

4.50<br />

10.69<br />

4.63<br />

8.00<br />

6.94<br />

17.26<br />

6.63<br />

1.44<br />

451<br />

4.75<br />

12.13<br />

5.25<br />

9.50<br />

7.69<br />

20.00<br />

7.38<br />

1.55<br />

Engineering Data<br />

Max<br />

Horsepower<br />

➂<br />

Per 100 RPM M ax. RPM<br />

Weight<br />

Max.<br />

Peak<br />

Change<br />

WR<br />

2<br />

Service<br />

Continuous Overload ➁ Per inch ➄ Change Per<br />

Axial<br />

Coupling Factor<br />

Not<br />

Torque Torque Weight of “C” WR<br />

2 Inch of “C” Capacity<br />

Size 1 Balanced<br />

Balanced<br />

(lb.-in.) (lb.-in.) (lb.) (lbs.) ( lb.-in.<br />

2<br />

) ( lb.-in. 2<br />

) (in.)<br />

50<br />

0.27<br />

6,000<br />

9,500<br />

170<br />

340<br />

1.<br />

0 0.075<br />

0.45<br />

0.016<br />

±0.023<br />

62<br />

0.46<br />

6,000<br />

8,600<br />

290<br />

580<br />

1.<br />

8 0.091<br />

1.<br />

4 0.027<br />

±0.028<br />

75<br />

0.65<br />

6,000<br />

8,200<br />

410<br />

820<br />

2.<br />

4 0.11<br />

1.<br />

8 0.051<br />

±0.032<br />

101<br />

1.30<br />

6,000<br />

7,500<br />

820<br />

1,640<br />

4.<br />

6 0.28<br />

6.<br />

0 0.16<br />

±0.038<br />

126<br />

2.22<br />

5,500<br />

6,800<br />

1,400<br />

2,800<br />

7.<br />

4 0.45<br />

13.<br />

0 0.36<br />

±0.046<br />

163<br />

3.09<br />

5,000<br />

6,300<br />

1,950<br />

3,900<br />

10.<br />

8 0.43<br />

27.<br />

4 0.70<br />

±0.057<br />

201<br />

5.60<br />

4,600<br />

5,700<br />

3,530<br />

7,060<br />

16.<br />

4 0.67<br />

60.<br />

3 1.<br />

6 ±0.067<br />

226<br />

10.<br />

0 4,100<br />

5,500<br />

6,300<br />

12,600<br />

24<br />

0.78<br />

104<br />

2.<br />

4 ±0.076<br />

263<br />

15.<br />

7 3,700<br />

5,000<br />

9,900<br />

19,800<br />

37<br />

0.93<br />

220<br />

4.<br />

1 ±0.089<br />

301<br />

23.<br />

5 3,300<br />

4,700<br />

14,800<br />

29,600<br />

54<br />

1.20<br />

425<br />

6.<br />

9 ±0.102<br />

351<br />

41.<br />

3 2,900<br />

4,400<br />

26,000<br />

52,000<br />

91<br />

1.80<br />

970<br />

13<br />

±0.118<br />

401<br />

60.<br />

3 2,700<br />

4,100<br />

38,000<br />

76,000<br />

135<br />

2.70<br />

1,860<br />

26<br />

±0.136<br />

451<br />

79.<br />

3 2,600<br />

3,800<br />

50,000<br />

100,000<br />

190<br />

3.10<br />

3,240<br />

36<br />

±0.154<br />

For ordering instructions, see Page 10-11.<br />

➀ All Thomas disc couplings meet NEMA frame sleeve bearing motor specifications without modification or the addition of end-float restrictin g<br />

devices.<br />

➁ Popular sized bores with keyway and setscrew are stocked. Consult your Rexnord representative for stock bore size availability .<br />

➂ See page 7 for explanation of RPM limits and balancing recommendations .<br />

➃ Weight<br />

and WR2 as shown are for maximum bores and standard. “C”.<br />

➄ Consult Rexnord for minimum rough bore sizes.<br />

20<br />

Note: Dimensions subject to change. Certified dimensions of ordered material furnished on request.<br />

A G<br />

N N<br />

B<br />

C<br />

F<br />

B<br />

ALSO AVAILABLE WITH TAPERED-BORE HUBS<br />

AXIAL<br />

CAPACITY<br />

➀