15-B Maintenance Mnl, GFZ-62075E/03 - Automation Service Srl

15-B Maintenance Mnl, GFZ-62075E/03 - Automation Service Srl

15-B Maintenance Mnl, GFZ-62075E/03 - Automation Service Srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

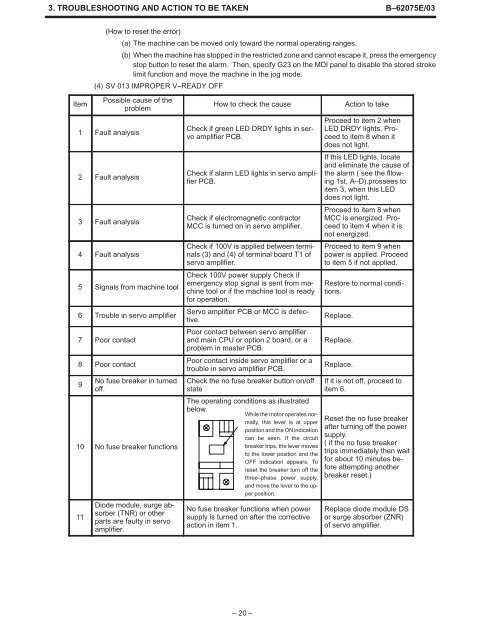

3. TROUBLESHOOTING AND ACTION TO BE TAKEN<br />

B–<strong>62075E</strong>/<strong>03</strong><br />

Item<br />

(How to reset the error)<br />

(a) The machine can be moved only toward the normal operating ranges.<br />

(b) When the machine has stopped in the restricted zone and cannot escape it, press the emergency<br />

stop button to reset the alarm. Then, specify G23 on the MDI panel to disable the stored stroke<br />

limit function and move the machine in the jog mode.<br />

(4) SV 013 IMPROPER V–READY OFF<br />

Possible cause of the<br />

How to check the cause<br />

Action to take<br />

problem<br />

1 Fault analysis<br />

2 Fault analysis<br />

3 Fault analysis<br />

4 Fault analysis<br />

5 Signals from machine tool<br />

6 Trouble in servo amplifier<br />

7 Poor contact<br />

8 Poor contact<br />

9<br />

No fuse breaker in turned<br />

off.<br />

10 No fuse breaker functions<br />

11<br />

Diode module, surge absorber<br />

(TNR) or other<br />

parts are faulty in servo<br />

amplifier.<br />

Check if green LED DRDY lights in servo<br />

amplifier PCB.<br />

Check if alarm LED lights in servo amplifier<br />

PCB.<br />

Check if electromagnetic contractor<br />

MCC is turned on in servo amplifier.<br />

Check if 100V is applied between terminals<br />

(3) and (4) of terminal board T1 of<br />

servo amplifier.<br />

Check 100V power supply Check if<br />

emergency stop signal is sent from machine<br />

tool or if the machine tool is ready<br />

for operation.<br />

Servo amplifier PCB or MCC is defective.<br />

Poor contact between servo amplifier<br />

and main CPU or option 2 board, or a<br />

problem in master PCB.<br />

Poor contact inside servo amplifier or a<br />

trouble in servo amplifier PCB.<br />

Check the no fuse breaker button on/off<br />

state<br />

The operating conditions as illustrated<br />

below.<br />

While the motor operates normally,<br />

this lever is at upper<br />

position and the ON indication<br />

can be seen. If the circuit<br />

breaker trips, the lever moves<br />

to the lower position and the<br />

OFF indication appears. To<br />

reset the breaker turn off the<br />

three–phase power supply,<br />

and move the lever to the upper<br />

position.<br />

No fuse breaker functions when power<br />

supply is turned on after the corrective<br />

action in item 1.<br />

Proceed to item 2 when<br />

LED DRDY lights. Proceed<br />

to item 8 when it<br />

does not light.<br />

If this LED lights, locate<br />

and eliminate the cause of<br />

the alarm ( see the fllowing<br />

1st, A–D).prossees to<br />

item 3, when this LED<br />

does not light.<br />

Proceed to item 8 when<br />

MCC is energized. Proceed<br />

to item 4 when it is<br />

not energized.<br />

Proceed to item 9 when<br />

power is applied. Proceed<br />

to item 5 if not applied.<br />

Restore to normal conditions.<br />

Replace.<br />

Replace.<br />

Replace.<br />

If it is not off, proceed to<br />

item 6.<br />

Reset the no fuse breaker<br />

after turning off the power<br />

supply.<br />

( if the no fuse breaker<br />

trips immediately then wait<br />

for about 10 minutes before<br />

attempting another<br />

breaker reset.)<br />

Replace diode module DS<br />

or surge absorber (ZNR)<br />

of servo amplifier.<br />

– 20 –