You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

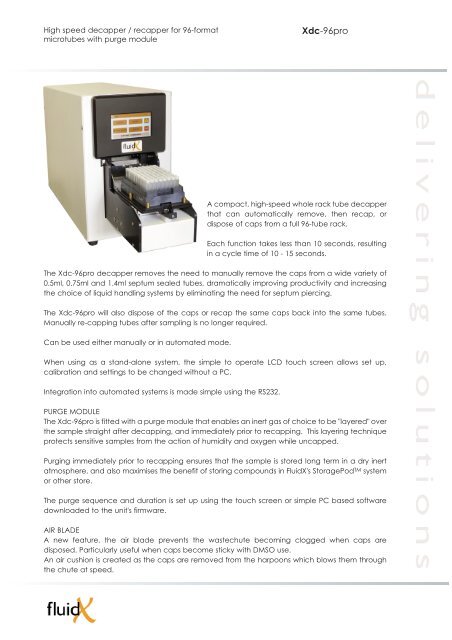

High speed decapper / recapper for 96-format<br />

microtubes with purge module<br />

<strong>Xdc</strong>-<strong>96pro</strong><br />

A compact, high-speed whole rack tube decapper<br />

that can automatically remove, then recap, or<br />

dispose of caps from a full 96-tube rack.<br />

Each function takes less than 10 seconds, resulting<br />

in a cycle time of 10 - 15 seconds.<br />

The <strong>Xdc</strong>-<strong>96pro</strong> decapper removes the need to manually remove the caps from a wide variety of<br />

0.5ml, 0.75ml and 1.4ml septum sealed tubes, dramatically improving productivity and increasing<br />

the choice of liquid handling systems by eliminating the need for septum piercing.<br />

The <strong>Xdc</strong>-<strong>96pro</strong> will also dispose of the caps or recap the same caps back into the same tubes.<br />

Manually re-capping tubes after sampling is no longer required.<br />

Can be used either manually or in automated mode.<br />

When using as a stand-alone system, the simple to operate LCD touch screen allows set up,<br />

calibration and settings to be changed without a PC.<br />

Integration into automated systems is made simple using the RS232.<br />

PURGE MODULE<br />

The <strong>Xdc</strong>-<strong>96pro</strong> is fitted with a purge module that enables an inert gas of choice to be "layered" over<br />

the sample straight after decapping, and immediately prior to recapping. This layering technique<br />

protects sensitive samples from the action of humidity and oxygen while uncapped.<br />

Purging immediately prior to recapping ensures that the sample is stored long term in a dry inert<br />

atmosphere, and also maximises the benefit of storing compounds in <strong>FluidX</strong>'s StoragePod TM system<br />

or other store.<br />

The purge sequence and duration is set up using the touch screen or simple PC based software<br />

downloaded to the unit's firmware.<br />

AIR BLADE<br />

A new feature, the air blade prevents the wastechute becoming clogged when caps are<br />

disposed. Particularly useful when caps become sticky with DMSO use.<br />

An air cushion is created as the caps are removed from the harpoons which blows them through<br />

the chute at speed.

<strong>Xdc</strong>-<strong>96pro</strong><br />

SPECIFICATIONS<br />

Dimensions<br />

Weight<br />

Power requirements<br />

User interface<br />

Cable interface<br />

Width 215mm<br />

Depth 680 mm with shuttle, 480mm without shuttle<br />

Height 350mm<br />

10kg<br />

AC115V / 230V +/-10%. Power less than 55W<br />

LCD Touch Screen for manual operation and system maintenance and<br />

calibration. Windows compatible maintenance and calibration software<br />

package provided.<br />

Serial RS232<br />

COMPATIBILITY<br />

Manufacturer Tube Volume<br />

Micronic TM Microtubes with CapCluster TM 1.4ml, 0.65ml<br />

Matrix Technologies TM TrakMates TM with SepraSeal TM Caps 1.4ml, 0.75ml, 0.5ml<br />

Abgene TM Cypher TM with Caps 1.2ml, 0.65ml<br />

<strong>FluidX</strong> TM EasyTrack TM Tubes and Caps 1.4ml, 0.65ml<br />

ORDERING INFORMATION<br />

Cat No<br />

<strong>Xdc</strong>-<strong>96pro</strong><br />

Description<br />

Automatic 96 tube rack decapper/re-capper, with Gas Purge for flushing with Nitrogen<br />

or Argon providing an inert atmosphere during storage or while tube is open.<br />

Air Blade Option for discarding solvent "sticky" caps to waste, prevents caps clumping<br />

together and blocking waste chute.<br />

Compatible with FLUIDX, Matrix / Micronic tubes and Individual caps including 1.4ml,<br />

0.75ml, 0.65ml**, 0.5ml tube variants.<br />

For Integration and Benchtop use only, use XDC-96Pro for integration or RS232 control.<br />

Please specify tube range when ordering, i.e. <strong>FluidX</strong>, Abgene, Matrix or Micronic.<br />

(**Some restrictions apply to smaller volume tubes)<br />

<strong>FluidX</strong> reserve the right to update and change product information without notice. © <strong>FluidX</strong> Ltd. 2009.<br />

Tel:+44 (0) 1625 861614 Email:info@fluidx.co.uk www.fluidx.co.uk