2002 Replacement Parts Catalog - cedip

2002 Replacement Parts Catalog - cedip

2002 Replacement Parts Catalog - cedip

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

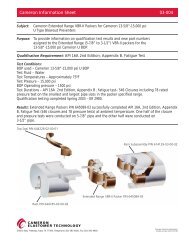

Cameron Elastomer Technology employees are experts in elastomer technology andcan take an idea from the testing phase through full product development.Today, there is a family of elastomer products specially formulated and designed tomeet the rigorous demands of the oilfield. These products, when used in CameronU, UII, T, TL, UL and UM, and C ram and D and DL annular BOPs, improve performance,extend service life, reduce downtime, and lower operating costs.CAMRAM, CAMRAM 350, CAMULAR , VBR-II, FLEXPACKER-NR andCAMLAST elastomer and DUROCAM elastomer have set new standards in performance.Each is uniquely Cameron, including design and manufacturing. Behindeach product is the absolute commitment to quality, performance and support thatthe industry has come to recognize as hallmarks of Cameron. CET is ISO 9001 and APIQ certified.An integral part of CET’s Katy facility is a temperature controlled elastomer warehouse.CET manufactured elastomer products and critical drilling metal spares arereadily available to meet customer requirements.BOP Elastomer <strong>Replacement</strong> <strong>Parts</strong>650 Ton Integrated Computer ControlledInjection Molding CenterTC1001 8 © <strong>2002</strong> Cooper Cameron, Cameron Division

Comparison of Cameron Ram-Type Blowout PreventersCameron offers a wide range of ram-type BOPs to meet the dynamic needs of thedrilling industry. The Cameron U BOP was initially designed for underwater drillingand is now the most widely used land BOP. Today, there are more U BOPs in thefield worldwide than any other ram-type BOP in the industry. As technology and theneeds of the drilling industry changed, Cameron responded by developing newram-type BOP designs. Cameron introduced the U II BOP for subsea applications andhas since developed the T BOP and the TL, UL and UM models for land and subseaapplications. Regardless of the model, all of the pressure containing components inCameron ram-type BOPs are forged to provide added safety and reliability.Comparison of Cameron Ram-Type BOPsDescription TL BOP UM BOP U BOPBore Sizes Working Pressures Working Pressures Working Pressures7-1/16” - 3000 psi WP 3000 psi WP- 5000 psi WP 5000 psi WP- 10,000 psi WP 10,000 psi WP- 15,000 psi WP 15,000 psi WP11” - - 3000 psi WP- 5000 psi WP 5000 psi WP- 10,000 psi WP 10,000 psi WP- 15,000 psi WP 15,000 psi WP13-5/8” - - 3000 psi WP- - 5000 psi WP10,000 psi WP 10,000 psi WP 10,000 psi WP- 15,000 psi WP 15,000 psi WP16-3/4” - - 3000 psi WP- - 5000 psi WP- - 10,000 psi WP18-3/4” 5000 psi WP - -10,000 psi WP - 10,000 psi WP15,000 psi WP - -20-3/4” - - 3000 psi WP21-1/4” - - 2000 psi WP- - 5000 psi WP- - 10,000 psi WP26-3/4” - - 3000 psi WPSide Ram Removal Yes No NoHydraulic StudTensioning*Not Required No Available on large sizesBonnet Seal Carrier Standard Available AvailableMechanical orHydromechanical LockingMechanismRamLocks/ST-Lock/WedgelocksWedgelocksWedgelocks*Not required when using bonnet seal carrierTC1001 9 © <strong>2002</strong> Cooper Cameron, Cameron Division

U BOP Hydraulic Control SystemThe U blowout preventer is designed so that hydraulic pressure opens and closes the rams and provides themeans for quick ram change-out.Ram closing pressure closes the rams. When the bonnet bolts are removed, closing pressure opens the bonnet.After the bonnet has moved to the fully extended position, the ram is clear of the body. An eyebolt can be installedin the top of each ram to lift it out of the preventer.Ram opening pressure opens the rams. Following ram change-out, this pressure closes the bonnets. The rams arepulled outward, near the bonnets, before the bonnets begin moving toward the preventer body. This assuresthat the rams never obstruct the bore or interfere with the pipe in the hole. Hydraulic pressure draws the bonnetstightly against the preventer body and the bonnet bolts are reinstalled to hold the bonnets closed.U BOP Operating Data and Fluid RequirementsLarge Bore Shear Bonnet Operating Data and Fluid RequirementsBore Size andWorkingPressureGals toOpenPipe Rams(1 Set)Gals toClosePipeRams(1 Set)LockingScrewTurns(Each End)ClosingRatioOpeningRatioBore Size andWorkingPressureGals to OpenPipe Rams(1 Set)Gals toClosePipe Rams(1 Set)LockingScrew Turns(Each End)7-1/16” All WP 1.3 1.3 18 6.9:1 2.2:1 7-1/16” All WP - - - - -11” Except 15,000 psi 3.4 3.5 27 7.3:1 2.5:111” Except 15,000psiClosingRatioOpeningRatio6.8 6.0 27 12.0:1 4.8:111” 15,000 psi 5.7 5.8 32 9.8:1 2.2:1 11” 15,000 psi 8.9 9.0 32 15.2:1 3.7:113-5/8” Except15,000 psi13-5/8” 15,000 psiModel B16-3/4” 3000 psiModel B16-3/4” 5000 psiModel B5.5 5.8 32 7.0:1 2.3:110.4 10.6 45 10.6:1 3.6:19.8 10.6 38 6.8:1 2.3:19.8 10.6 38 6.8:1 2.3:113-5/8” Except15,000 psi13-5/8” 15,000 psiModel B16-3/4” 3000 psiModel B16-3/4” 5000 psiModel B10.5 10.9 32 10.8:1 4.5:116.0 16.2 45 16.2:1 6.0:118.2 19.0 38 10.4:1 4.4:118.2 19.0 38 10.4:1 4.4:116-3/4” 10,000 psi 11.6 12.5 45 6.8:1 2.3:1 16-3/4” 10,000 psi 18.2 19.1 45 10.4:1 4.4:118-3/4” 10,000 psi 21.3 23.1 54 7.4:1 3.7:1 18-3/4” 10,000 psi - - - - -20-3/4” 3000 psi 8.1 8.7 46 7.0:1 1.3:1 20-3/4” 3000 ps 14.3 14.9 46 10.8:1 1.7:121-1/4” 2000 psi 9.0 8.7 46 7.0:1 1.3:1 21-1/4” 2000 psi 14.3 14.9 46 10.8:1 1.7:121-1/4” 5000 psi 27.3 30.0 54 7.2:1 4.0:1 21-1/4” 5000 psi - - - - -21-1/4” 10,000 psi 24.5 26.9 51 7.2:1 4.0:1 21-1/4” 10,000 psi - - - - -26-3/4” 3000 psi 10.1 10.8 58 7.0:1 1.0:1 26-3/4” 3000 ps - - - - -TC1001 12 © <strong>2002</strong> Cooper Cameron, Cameron Division

U BOP SpecificationsThe following specifications apply to typical Cameron U type BOPs. Your Cameron representativecan provide information on non-standard BOP assemblies.• Side outlets to 4-1/16” (7-1/16” on 26-3/4” BOPs) can be provided beneatheach set of rams on either or both sides of U BOPs. Side outlets can bestudded, open-face flange or clamp hub with the same pressure rating as thevertical run connections.• Flanges conform to API standard 6A and/or 16A. Hubs conform to API 16A orapplicable standards. Type 6BX flanges are standard for 10,000 and 15,000 psiworking pressures and for 5000 psi for 13-5/8” and larger bore BOPs.Hydraulic control connections for operation of rams and bonnets are 1” NPT. There aretwo connections for each set of rams. Wedgelock connections are ½” NPT.The capital letters in the following designations refer to the U BOP dimensional viewsand dimensional charts shown on the following pages.A-1 Length - bonnets closed, locking screws lockedA-2 Length - bonnets opened, locking screws unlockedA-3 Length - bonnets closed, with wedgelocksA-4 Length - bonnets opened, with wedgelocksB-1 Height - flangedB-2 Height - clamp hubsB*** Height - added height if 30” spacing is required for doubleCDWidth - no side outletsCenterline of preventer to outlet flange or hub face. This distance is variable andmust be determined per individual specifications.E-1 Centerline of side outlet below rams to bottom flange faceE-2 Centerline of side outlet below rams to bottom hub faceF-1 Top of upper ram to top flange faceF-2 Top of upper ram to top hub faceG Height of ramH-1 Centerline of side outlet between rams to bottom flange faceH-2 Centerline of side outlet between rams to bottom hub faceJ Top of lower ram to bottom of upper ramTC1001 13 © <strong>2002</strong> Cooper Cameron, Cameron Division

7-1/16” 3000 - 11” 10,000 psi WP U BOP Part NumbersItemNo.DescriptionQtySglQtyDbl7-1/16”3000psiModel II7-1/16”5000psiModel II1 Body 1 1 - - - - - - -2 Intermediate Flange 2 4 030266-03-00-01 030266-03-00-01 030266-01-01 030266-01-01 030267-03 030267-03 030267-032A Intermediate Flange/Shear - - 041499-03** 041499-03** 041499-01** 041499-01** 041457-03** 041457-03** 041457-03**3 Bonnet 2 4 030278-04 030278-04 030278-02 030278-01 030268-01 030268-02 030268-034 Ram Assembly 2 4 644504-( ) 644504-( ) 644504-( ) 644504-( ) 644219-( ) 644219-( ) 644219-( )5 Piston, Operating 2 4 2010520-03 2010520-03 2010520-03 2010520-03 673178 673178 163129-015A Piston, Operating/Shear - - 049116-01** 049116-01** 049116-01** 049116-01** 698914** 698914** 698914**6 Cylinder, Operating 2 4 030274-02 030274-02 030274-02 030274-02 030274-03 030274-03 030274-036A Cylinder, Operating/Shear - - 041365-02 041365-02 041365-02 041365-02 041365-03** 041365-03** 041365-03**7 Housing, Locking Screw 2 4 030308-01 030308-01 030308-01 030308-01 030308-02 030308-02 030308-028 Locking Screw 2 4 030326 030326 030326 030326 030365 030365 0303658A Locking Screw/Shear - - 049258-01 049258-01 049258-01 049258-01 046628-01 046628-01 046628-019 Piston, Ram Change/Open 2 4 030324 030324 030324 030324 030362 030362 03036210 Piston, Ram Change/Close 2 4 030325 030325 030325 030325 030363 030363 03036311 Cylinder, Ram Change 4 8 030273-02 030273-02 030273-02 030273-02 030273-03 030273-03 030273-0312 Bolt, Bonnet 8 16 030312-06 030312-06 030312-07 030312-01 030312-04 030312-03 030312-0512A Bolt, Bonnet/Shear - - 041366-06 041366-06 041366-07 041366-22 041366-04 041366-03 041366-0513 Stud, Locking Screw Housing 16 32 219065-10-04-41 219065-10-04-41 219065-10-04-41 219065-10-04-41 219065-12-05-01 219065-12-05-01 219065-12-05-0113A Stud, Locking Screw Housing/Shear - - 038732-57-00-54 038732-57-00-54 219065-10-05-41 219065-10-05-41 219065-12-06-51 219065-12-06-51 219065-12-06-5114 Nut, Locking Screw Housing 16 32 2709000-10-01 2709000-10-01 2709000-10-01 2709000-10-01 2709000-12-01 2709000-12-01 2709000-12-0115 Check Valve, Plastic Packing 2 4 M517988 M517988 M517988 M517988 M517988 M517988 M51798816 Screw, Plastic Packing 2 4 005940-09 005940-09 005940-09 005940-09 005940-09 005940-09 005940-0917 Pipe Plug, Plastic Packing 2 4 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-1018 Ring, Plastic Packing 2 4 2010178-01 2010178-01 2010178-01 2010178-01 2010178-02 2010178-02 2010178-0219 Ring, Plastic Energizing 2 4 018586-12 018586-12 018586-12 018586-12 018586-13 018586-13 018586-1320 Seal Ring, Connecting Rod 2 4 212741-37-00-01 212741-37-00-01 212741-37-00-01 212741-37-00-01 212741-38-00-01 212741-38-00-01 212741-38-00-0121 Ring Back-Up 4 8 - - 021792-21 021792-21 021792-22 021792-22 021792-2222 Seal, Bonnet 2 4 644197-01-00-01 644197-01-00-01 644197-01-00-01 644197-01-00-01 644197-02-00-01 644197-02-00-01 644197-02-00-0123 Pin, Ram Guide 4 8 030313-02 030313-02 030313-02 030313-02 030313-03 030313-03 030313-0324 O-Ring, Operating Cylinder 4 8 702645-44-61 702645-44-61 702645-44-61 702645-44-61 702645-45-11 702645-45-11 702645-45-1125 O-Ring, Operating Piston Rod to Int Flg 2 4 018492-92 018492-92 018492-92 018492-92 018492-91 018492-91 018492-9126 Lip Seal, Operating Piston 2 4 710541 710541 710541 710541 710539 710539 71053927 Seal Ring, Tail Rod 2 4 212741-32 212741-32 212741-32 212741-32 212741-33-00-01 212741-33-00-01 212741-33-00-0128 O-Ring, Wiping 2 4 702645-33-11 702645-33-11 702645-33-11 702645-33-11 702645-33-51 702645-33-51 702645-33-5129 O-Ring, Ram Change Piston to Body 4 8 702645-32-41 702645-32-41 702645-32-41 702645-32-41 702645-32-61 702645-32-61 702645-32-6130 O-Ring, Ram Change Piston Rod to Int Flg 4 8 702645-32-91 702645-32-91 702645-32-91 702645-32-91 702645-33-11 702645-33-11 702645-33-1131 O-Ring, Ram Change Cylinder to Int Flg 4 8 702645-33-81 702645-33-81 702645-33-81 702645-33-81 031423-25-13-85 031423-25-13-85 031423-25-13-8532 O-Ring, Ram Change Cylinder to Bonnet 4 8 702645-34-21 702645-34-21 702645-34-21 702645-34-21 2010180-02 2010180-02 2010180-0233 O-Ring, Ram Change Piston 4 8 702645-33-21 702645-33-21 702645-33-21 702645-33-21 702645-33-51 702645-33-51 702645-33-5134 O-Ring, Bonnet Bolt Retainer 8 16 702645-22-31 702645-22-31 702645-22-91 702645-23-21 702645-22-71 702645-22-91 702640-23-4135 Cap Screw, Int Flange to Bonnet 16*** 32*** 702585-22-00-50 702585-22-00-50 702585-22-00-50 702585-22-00-50 702585-25-00-50 702585-25-00-50 702585-25-00-5036 Gland, Bleeder 2 4 017454-08 017454-08 017454-08 017454-08 017454-08 017454-08 017454-0837 Plug, Bleeder 2 4 017454-09 017454-09 017454-09 017454-09 017454-09 017454-09 017454-0938 Lifting Eye 2 2 011849-01 011849-01 011849-01 011849-01 011849-01 011849-01 011849-0139 Packing, Plastic 10 20 007650-25 007650-25 007650-25 007650-25 007650-25 007650-25 007650-2540 Washer 2 4 689523-04 689523-04 689523-04 689523-04 689523-05 689523-05 689523-0541 Ring, Retainer 2 4 018572-83 018572-83 018572-83 018572-83 018572-84 018572-84 018572-8442 Wear Ring, Operating Piston 2 4 049223-03 049223-03 049223-03 049223-03 049223-02 049223-02 049223-0243 Spacer, Shear**** - - 687117-01 687117-01 687117-01 687117-01 687117-02 687117-02 687117-027-1/16”10,000psiModel II7-1/16”15,000psiModel II****A large bore shear bonnet is available for these sizes. For part numbers, see page 24.****Part numbers shown are for old style shear bonnets. For current model large bore shear bonnet part numbers, see page .****13-5/8” through 16-3/4” and 20-3/4” through 26-3/4” require 24 for single and 48 for double. The 18-3/4” requires 32 for single and 64 double.****Required on all 11” 15,000 psi and 16-3/4” 10,000 psi BOPs with manual locking screws.*11”3000psiModel II* 11”5000psiModel II*11”10,000psiModel IITC1001 17 © <strong>2002</strong> Cooper Cameron, Cameron Division

123437363810422911624215161735339526243231301478133141819214041422252320Double U BOPSD017500TC1001 18 © <strong>2002</strong> Cooper Cameron, Cameron Division

11” 15,000 - 16-3/4” 5000 psi WP U BOP Part NumbersItemNo.DescriptionQtySglQtyDbl*11”15,000psiModel 79*13-5/8”3000psiModel II1 Body 1 1 - - - - - - -2 Intermediate Flange 2 4 049391-01 030270-01-00-02 030270-01-00-02 031216 698899 038944 0388442A Intermediate Flange/Shear - - * 686242** 686242** 686767** 615538-01 - 0414083 Bonnet 2 4 031241 030284-02 030284-01 031241 691849 038843-02 038843-014 Ram Assembly 2 4 644222-( ) 644225-( ) 644225-( ) 644225-( ) 644228-( ) 644231-( ) 644231-( )5 Piston, Operating 2 4 698481 679816 679816 678512 698996 614374-01 6895625A Piston, Operating/Shear - - * 687542** 687542** 670512-00-00-02 615539-01 - 694085**6 Cylinder, Operating 2 4 030274-01 030274-01 030274-01 030274-01 030274-06 030274-06 030274-066A Cylinder, Operating/Shear - - - 041365-01** 041365-01** 041365-01** - - 041365-06**7 Housing, Locking Screw 2 4 030308-03 030308-03 030308-03 030308-03 030308-06 030308-06 030308-068 Locking Screw 2 4 030846 030307 030307 030307 695234 038901 0389018A Locking Screw/Shear - - - 030846 030846 030846 - - 6952349 Piston, Ram Change/Open 2 4 031239 030310 030310 031239 038847 038946 03884710 Piston, Ram Change/Close 2 4 031238 030309 030309 031238 038848-01 038947 038848-0111 Cylinder, Ram Change 4 8 030273-01 030273-01 030273-01 030273-01 030273-06 030273-07 030273-0612 Bolt, Bonnet 8 16 030312-12 030312-09 030312-01 236519-34-11 030312-25 030312-17 030312-1612A Bolt, Bonnet/Shear - - - 041366-09 041366-01 041366-12 - - 041366-1613 Stud, Locking Screw Housing 16 32 219065-14-07-51 005918-76-10 005918-76-10 005918-76-10 219065-14-07-51 005918-78-10 219065-14-04-7113A Stud, Locking Screw Housing/Shear - - - 219065-14-07-51 219065-14-07-51 219065-14-07-51 - - 005918-34-1014 Nut, Locking Screw Housing 16 32 2709000-14-01 2709000-14-01 2709000-14-01 2709000-14-01 2709000-14-01 2709000-14-01 2709000-14-0115 Check Valve, Plastic Packing 2 4 M517988 M517988 M517988 M517988 M517988 M517988 M51798816 Screw, Plastic Packing 2 4 005940-09 005940-09 005940-09 005940-09 005940-09 005940-09 005940-0917 Pipe Plug, Plastic Packing 2 4 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-1018 Ring, Plastic Packing 2 4 012469-24 012469-24 012469-24 012469-24 012469-24 012469-52 012469-5219 Ring, Plastic Energizing 2 4 018586-13 018586-01 018586-01 018586-01 018586-01 018586-14 018586-1420 Seal Ring, Connecting Rod 2 4 212741-36-00-02 212741-36-00-01 212741-36-00-01 212741-36-00-01 212741-36-00-01 212741-44 212741-4421 Ring Back-Up 4+ 8+ 021792-26 - - 021792-26 021792-26 - -22 Seal, Bonnet 2 4 049272-03 644197-03-00-01 644197-03-00-01 644197-03-00-01 644196-01-00-01 644197-04-00-01 644197-04-00-0123 Pin, Ram Guide 4 8 030313-01 030313-01 030313-01 030313-01 030313-08 030313-06 030313-0624 O-Ring, Operating Cylinder 4 8 702645-45-51 702645-45-51 702645-45-51 702645-45-51 702645-46-11 702645-46-11 702645-46-1125 O-Ring, Operating Piston Rod to Int Flg 2 4 018492-90 018492-90 018492-90 018492-90 018492-90 2708811-01 2708811-0126 Lip Seal, Operating Piston 2 4 710538 710538 710538 710538 710542 710542 71054227 Seal Ring, Tail Rod 2 4 212741-34-00-01 212741-34-00-01 212741-34-00-01 212741-34-00-01 212741-45 212741-45 212741-4528 O-Ring, Wiping 2 4 702645-33-71 702645-33-71 702645-33-71 702645-33-71 702645-34-21 702645-34-21 702645-34-2129 O-Ring, Ram Change Piston to Body 4 8 702645-32-81 702645-32-81 702645-32-81 702645-32-81 702645-33-21 702645-33-21 702645-33-2130 O-Ring, Ram Change Piston Rod to Int Flg 4 8 702645-33-31 702645-33-31 702645-33-31 702645-33-31 031423-21-13-85 031423-21-13-85 031423-21-13-8531 O-Ring, Ram Change Cylinder to Int Flg 4 8 702645-34-61 702645-34-61 702645-34-61 702645-34-61 702645-35-41 702645-35-41 702645-35-4132 O-Ring, Ram Change Cylinder to Bonnet 4 8 702645-42-51 702645-42-51 702645-42-51 702645-42-51 702645-43-41 702645-43-41 702645-43-4133 O-Ring, Ram Change Piston 4 8 702645-33-81 702645-33-81 702645-33-81 702645-33-81 702645-34-41 702645-34-41 702645-34-4134 O-Ring, Bonnet Bolt Retainer 8 16 702645-23-91 702645-23-11 702645-23-21 702645-23-91 702645-24-51 702645-23-21 702645-23-7135 Cap Screw, Int Flange to Bonnet 16*** 32*** 702585-25-00-54 702585-25-00-44 702585-25-00-44 702585-25-00-54 702585-31-00-54 702585-31-00-44 702585-31-00-5436 Gland, Bleeder 2 4 017454-08 017454-08 017454-08 017454-08 017454-08 017454-08 017454-0837 Plug, Bleeder 2 4 017454-09 017454-09 017454-09 017454-09 017454-09 017454-09 017454-0938 Lifting Eye 2 2 011849-01 011849-01 011849-01 011849-01 011849-01 011849-01 011849-0139 Packing, Plastic 10 20 007650-25 007650-25 007650-25 007650-25 007650-25 007650-25 007650-2540 Washer 2 4 689523-01 689523-01 689523-01 689523-01 689523-01 689523-02 689523-0241 Ring, Retainer 2 4 018572-85 018572-85 018572-85 018572-85 018572-85 033186-85 033186-8542 Wear Ring, Operating Piston 2 4 049223-01 049223-01 049223-01 049223-01 049223-04 049223-04 049223-0443 Spacer, Shear**** - - 687117-03 687117-03 687117-03 687117-03 687117-05 - 687117-05*13-5/8”5000psiModel II*13-5/8”10,000psiModel II*13-5/8”15,000psiModel B* 16-3/4”3000psiModel B****A large bore shear bonnet is available for these sizes. For part numbers, see page 24.+ 11” 15,000 psi requires 8 for single, 16 for double.****Part numbers shown are for old style shear bonnets. For current model large bore shear bonnet part numbers, see page .****13-5/8” through 16-3/4” and 20-3/4” through 26-3/4” require 24 for single and 48 for double. The 18-3/4” requires 32 for single and 64 double.****Required on all 11” 15,000 psi and 16-3/4” 10,000 psi BOPs with manual locking screws.*16-3/4”5000psiModel BTC1001 19 © <strong>2002</strong> Cooper Cameron, Cameron Division

123437363810422911624215161735339526243231301478133141819214041422252320Double U BOPSD017500TC1001 20 © <strong>2002</strong> Cooper Cameron, Cameron Division

16-3/4” 10,000 - 26-3/4” 3000 psi WP U BOP Part NumbersItemNo.DescriptionQtySglQtyDbl*16-3/4”10,000psiModel II18-3/4”10,000psiModel II1 Body 1 1 - - - - - - -2 Intermediate Flange 2 4 691848 041458 236499-71-11-03 030911-01 - 615369-01 -2A Intermediate Flange/Shear - - * - 041496-01** 041496-01** 049955-01 615418-01 0383273 Bonnet 2 4 691849 041459 030835-01 030835-02 049963-01 041357 0383264 Ram Assembly 2 4 644231-( ) 644234-( ) 044256-( ) 044256-( ) 044262-( ) 044262-( ) 044260-( )5 Piston, Operating 2 4 692828 041460 236501-71-11-03 690058-03 049954-01 041356 614376-015A Piston, Operating/Shear - - 615536-01 - 693405** 693405** - 041374** -6 Cylinder, Operating 2 4 041365-06 030274-13 030274-04 030274-04 030274-11 030274-11 030274-056A Cylinder, Operating/Shear - - - - 041365-04** 041365-04** - 041365-11** -7 Housing, Locking Screw 2 4 030308-06 030308-09 030308-04 030308-04 030308-08 030308-08 030308-058 Locking Screw 2 4 695234 041085 030846 030846 041085 041085 0342338A Locking Screw/Shear - - - - 034233 034233 - - -9 Piston, Ram Change/Open 2 4 692756 040961 030848 030848 041064 041064 03817410 Piston, Ram Change/Close 2 4 692759 040960 030849 030849 041065 041065 03832411 Cylinder, Ram Change 4 8 030273-13 030273-09 030273-04 030273-04 030273-11 030273-11 030273-0512 Bolt, Bonnet 8 16 030312-24 030312-23 030312-10 030312-11 030312-26 030312-21 030312-1312A Bolt, Bonnet/Shear - - - - 041366-10 041366-11 - 041366-21 -13 Stud, Locking Screw Housing 16 32 219065-14-06 005919-38-10 219065-14-06-01 219065-14-06-01 005919-38-10 005919-38-10 219065-14-06-0113A Stud, Locking Screw Housing/Shear - - - - 219065-14-07-51 219065-14-07-51 - - -14 Nut, Locking Screw Housing 16 32 2709000-14-01 270900-18-01 2709000-14-01 270900-14-01 2709000-18-01 2709000-18-01 2709000-14-0115 Check Valve, Plastic Packing 2 4 M517988 M517988 M517988 M517988 M517988 M517988 M51798816 Screw, Plastic Packing 2 4 005940-09 005940-09 005940-09 005940-09 005940-09 005940-09 005940-0917 Pipe Plug, Plastic Packing 2 4 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-10 005930-05-1018 Ring, Plastic Packing 2 4 012469-52 012469-72 012469-24 012469-24 012469-70 012469-70 012469-2419 Ring, Plastic Energizing 2 4 018586-14 018586-19 018586-01 018586-01 018586-18 018586-18 018586-0120 Seal Ring, Connecting Rod 2 4 212741-44 212741-60 212741-36-00-01 212741-36-00-01 011741-58-00-01 011741-58-00-01 212741-36-00-0121 Ring Back-Up 4 8 021792-34 021793-40† - - 021793-39 021793-39 -22 Seal, Bonnet 2 4 644197-04-00-01 644197-05-00-01 046613-16-00-01 046613-16-00-01 644197-08 644197-08 644197-09-00-0123 Pin, Ram Guide 4 8 030313-06 030313-07 030313-04 030313-04 030313-07 030313-07 030313-0524 O-Ring, Operating Cylinder 4 8 702645-46-11 702645-46-91 702645-45-51 702645-45-51 702645-46-91 702645-46-91 702645-45-5125 O-Ring, Operating Piston Rod to Int Flg 2 4 2708811-01 041602-04-13-85 018492-90 018492-90 030101-88-13-85 030101-88-13-85 018492-9026 Lip Seal, Operating Piston 2 4 710542 710543 710538 710538 710544 710544 71053827 Seal Ring, Tail Rod 2 4 212741-45 212741-36-00-01 212741-34-00-01 212741-34-00-01 212741-36-00-01 212741-36-00-01 212741-34-00-0128 O-Ring, Wiping 2 4 702645-34-21 702645-34-51 702645-33-71 702645-33-71 702645-34-51 702645-34-51 702645-33-7129 O-Ring, Ram Change Piston to Body 4 8 702645-33-21 702645-34-01 702645-33-61 702645-33-61 702645-34-31 702645-34-31 702645-34-4130 O-Ring, Ram Change Piston Rod to Int Flg 4 8 31423-21-13-85 2010180-02 702645-34-11 702645-34-11 702645-35-11 702645-35-11 702645-34-9131 O-Ring, Ram Change Cylinder to Int Flg 4 8 702645-35-41 702645-43-51 702645-43-71 702645-43-71 702645-44-01 702645-44-01 702645-43-9132 O-Ring, Ram Change Cylinder to Bonnet 4 8 702645-43-41 702645-43-81 702645-43-91 702645-43-91 702645-44-21 702645-44-21 702645-44-1133 O-Ring, Ram Change Piston 4 8 702645-34-41 030101-83-13-85 702645-42-51 702645-42-51 702645-43-11 702645-43-11 702645-42-9134 O-Ring, Bonnet Bolt Retainer 8 16 702645-24-51 702645-24-71 702645-22-91 702645-22-71 702645-24-71 702645-24-81 702645-23-9135 Cap Screw, Int Flange to Bonnet 16*** 32*** 702585-31-00-72 702585-36-00-76 702585-28-00-50 702585-28-00-50 702585-36-00-93 702585-36-00-93 702585-31-00-7036 Gland, Bleeder 2 4 017454-08 017454-08 017454-08 017454-08 017454-08 017454-08 017454-0837 Plug, Bleeder 2 4 017454-09 017454-09 017454-09 017454-09 017454-09 017454-09 017454-0938 Lifting Eye 2 2 011849-01 011849-01 011849-01 011849-01 011849-01 011849-01 011849-0139 Packing, Plastic 10 20 007650-25 007650-25 007650-25 007650-25 007650-25 007650-25 007650-2540 Washer 2 4 689523-02 689523-03 689523-01 689523-01 002353-46 002353-46 689523-0141 Ring, Retainer 2 4 033186-35 033186-01-04 018572-85 018572-85 033186-92 033186-92 018572-8542 Wear Ring, Operating Piston 2 4 049223-04 049223-07 049223-10 049223-01 049223-11 049223-08 049223-1043 Spacer, Shear**** - - 687117-05 - 687117-03 687117-03 - - -*20-3/4”3000psiModel II* 21-1/4”2000psiModel II21-1/4”5000psiModel II****A large bore shear bonnet is available for these sizes. For part numbers, see page 24.†Requires 2 for single and 4 for double.****Part numbers shown are for old style shear bonnets. For current model large bore shear bonnet part numbers, see page .****13-5/8” through 16-3/4” and 20-3/4” through 26-3/4” require 24 for single and 48 for double. The 18-3/4” requires 32 for single and 64 double.****Required on all 11” 15,000 psi and 16-3/4” 10,000 psi BOPs with manual locking screws.21-1/4”10,000psiModel II26-3/4”3000psiModel IITC1001 21 © <strong>2002</strong> Cooper Cameron, Cameron Division

Bonnet Rebuild Softgoods KitsFor popular size U BOPs, a bonnet rebuild softgoods kit is available to provide all parts requiredto reseal the operating system.Kit parts are shrink-film packed to prevent loss and assure long shelf life. The kits areless expensive than individual parts. All parts in each kit are identified with part numbersand parts list index numbers.2434284233272629243231301821251920U BOP Bonnet Softgoods ComponentsSD 017515TC1001 22 © <strong>2002</strong> Cooper Cameron, Cameron Division

Kit Part NumbersBOP Size (in.) Pressure Rating/Bonnet Type Kit Part Number*7-1/16 3000, 5000, 10,000 and 15,000 psi All 644909-0111 3000, 5000, and 10,000 psi Pipe 644909-0211 15,000 psi All 644831-0813-5/8 3000, 5000, and 10,000 psi Pipe 644909-0313-5/8 15,000 psi All 644831-1216-3/4 5000 psi Pipe 644831-1416-3/4 10,000 psi All 644831-1518-3/4 10,000 psi All 644909-0420-3/4 3000 psi Pipe 644831-1721-1/4 2000 psi Pipe 644831-1821-1/4 5000 psi All 644831-1921-1/4 7500 psi All 644381-2021-1/4 10,000 psi Pipe 644831-2126-3/4 3000 psi All 644831-22*One kit contains softgoods for one bonnetU BOP Bonnet Rebuild Softgoods Kit ComponentsItem Number*Description18 Ring, Plastic Packing19 Ring, Plastic Energizing20 Seal Ring, Connecting Rod21 Ring, Backup24 O-Ring, Operating Cylinder25 O-Ring, Operating Piston Rod to Intermediate Flange26 Lip Seal, Operating Piston27 Seal Ring, Tail Rod28 O-Ring, Wiping29 O-Ring, Ram Change Piston to Body30 O-Ring, Ram Change Piston Rod to Intermediate Flange31 O-Ring, Ram Change Cylinder to Intermediate Flange32 O-Ring, Ram Change Piston to Bonnet33 O-Ring, Ram Change Piston34 O-Ring, Bonnet Bolt Retainer39 Packing, Plastic**42 Wear Ring, Operating Piston44 O-Ring (not shown)TC1001 23 © <strong>2002</strong> Cooper Cameron, Cameron Division

Drill Pipe Shearing RequirementsThe minimum shearing configurations needed for each size U BOP to meet the requirements ofthe second edition of API 16A are listed in the following chart. Each shearing configuration iscapable of shearing the corresponding pipe at a closing pressure equal to or less than 2800 psi.For further information on shearing requirements for different pipe sizes and grades, contactyour Cameron representative.API Designated Size Ram Type Pressure Rating (psi) Pipe OD (In.) Pipe lb/ft Pipe Grade Shearing Configuration7-1/16” SBR All 3-1/2 13.3 S Shear Bonnets with Tandem Boosters11” SBR 10,000 and Lower 5 19.5 E Shear Bonnets with Tandem Boosters11” DS/ISR 10,000 and Lower 5 19.5 E Large Bore Shear Bonnets11” SBR 15,000 and Higher 5 19.5 G Large Bore Shear Bonnets with Tandem Boosters13-5/8” SBR 10,000 and Lower 5 19.5 G Shear Bonnets with Tandem Boosters13-5/8” DS/ISR 10,000 and Lower 5 19.5 G Large Bore Shear Bonnets13-5/8” SBR 15,000 and Higher 5 19.5 S Large Bore Shear Bonnets16-3/4” SBR All 5 19.5 S Large Bore Shear Bonnets18-3/4” SBR All 5 19.5 S Standard Bonnets20-3/4” SBR 3000 and Lower 5 19.5 G Shear Bonnets with Tandem Boosters21-1/4” SBR 3000 and Lower 5 19.5 G Shear Bonnets with Tandem Boosters21-1/4” SBR 5000 and Higher 5 19.5 S Standard Bonnets21-1/4 SBR 10,000 and Higher 5 19.5 G Standard BonnetsLarge Bore Shear Bonnets12A**3A42A5A26A24A2ALarge Bore Shear RamBonnet AssemblySD-017503ItemNo.**2ADescription(2 Required perCavity)Bonnet Assembly(Right)Bonnet Assembly(Left)IntermediateFlange/Shear11”3000 psi Model II11”5000 psiModel II11”10,000 psiModel II11”15,000 psiModel 7913-5/8”3000 psiModel 1113-5/8”5000 psiModel II13-5/8”10,000 psiModel II13-5/8”15,000 psiModel B16-3/4”5000 psiModel B16-3/4”10,000 psiModel II20-3/4”3000 psiModel II21-1/4”2000 psiModel II615195-01 615194-01-00-01 614596-01-00-01 615419-01 615196-01 615191-01-00-01 614498-01-00-02 615540-01 615530-01 615537-01 615526-01 615525-01615195-02 615194-02-00-01 614596-02-00-01 615419-02 615196-02 615191-01-00-01 614498-02 615540-02 615530-02 615537-02 615526-02 615525-02615188-01 615188-01 615188-01 615459-01 615192-01 615192-01-00-01 614766-01-00-02 615538-01 615528-01 615535-01 615523-01 615523-013A Bonnet/Shear 615189-03 615189-02 615189-01 615640-01 615143-02 615143-01 614772-01 615448-01 615527-01 615534-01 615522-01 615522-025A24A26A42AOperatingPiston/ShearO-Ring, Int Flg toBonnet LipLip Seal,OperatingPiston/ShearWear Ring,OperatingPiston/Shear615190-02-00-01 615190-02-00-01 615190-02-00-01 615457-01 615209-01 615209-01-00-01 614760-01-00-02 615539-01 615529-01 615536-01 615524-01 615524-01702645-45-51 702645-45-51 702645-45-51 702645-45-81 702645-45-81 702645-45-81 702645-45-81 702645-46-51 702645-46-51 702645-46-51 702645-45-81 702645-45-81710586 710586 710586 710542 710542 710542 710542 710588 710588 710588 710542 710542049223-15 049223-15 049223-15 049223-04 049223-04 049223-04 049223-04 049223-17 049223-17 049223-17 049223-14 049223-14**Two shear bonnet assemblies, one right and one left, are required per cavity. The shear bonnet assembly consists of all items shown on the illustration.**See pages 17, 19 and 21 for bonnet bolt part numbers.TC1001 24 © <strong>2002</strong> Cooper Cameron, Cameron Division

Tandem Boosters for U BOPsA BOP equipped with tandem boosters can deliver increased shearing force while not increasingthe wear and tear on the packers. Tandem boosters approximately double theforce available to shear pipe. Since the tailrod of the tandem booster has the same strokeas the BOP’s operating piston, the standard shear locking mechanism can be installed onthe outside end of the booster. For information on lock screws and the required spacers,see pages 17, 19 and 21.For information concerning applications where a tandem booster is required, consultyour Cameron representative.21211139417 71016515143861Tandem Booster Assembly23SD-017504ItemNo.20-3/4” 3000 psi and21-1/4” 2000 psi7-1/16” 3000, 5000, 10,000 and 15,000 psi* 11’ 3000, 5000, and 10,000 psiDescriptionQty Part Number Qty Part Number Qty Part Number** Tandem Booster Assembly 1 645414-01 1 645219-01 1 645251-011 Cylinder 2 644959-01 2 645113-01 2 645113-042 Cylinder Head 2 645413-01 2 645171-01 2 645171-033 Piston 2 644961-01 2 2032370-02 2 645172-034 Tailrod 2 644962-01 2 645173-01 2 645173-045 Adapter Plate 2 644963-01 2 645115-01 2 645115-036 Screw, SDC HD Cap 16 018541-34 16 018542-13 16 K2504057 O-Ring 2 702645-24-91 2 702645-36-11 2 702645-37-118 Seal Ring 2 710541 2 712352 2 7105389 Wear Ring, Operating Piston 2 049223-03 2 049223-21 2 049223-0110 Filter, Muffler 2 710621 2 710621 2 71041711 Seal, Lip 2 212741-32 2 212741-33-00-01 2 212741-34-00-0112 Seal Ring 2 710620 2 712351 2 71041913 Wear Ring, Cylinder 2 644443-02 2 644443-03 2 645215-0114 Seal Ring 2 705955 2 712445 2 71041815 O-Ring 2 702645-33-11 2 702645-33-51 2 702645-33-7116 Alignment Ring 2 645116-02 2 645116-01 2 645116-0317 Pipe Plug 2 201018 2 201018 2 005930-05-1018 Connector, Tubing 1 675029-09 - - 4 204887-10-06-5719 Cross 1 006347-08 1 675029-52 2 675029-2320 Nipple, Pipe Regular 1 685904-06-00-30 1 685902-07-00-30 1 685902-07-00-3021 Hose Assembly 2 2708020 2 2708021 2 71137422 Connector, Tubing 2 678046-17 2 204887-10-05-56 - -23 Stud, Double End 16 219065-10-04-41 16 219065-12-05-01 - -24 Connector, Tubing 1 204888-08-05-56 - - - -25 Nipple, Pipe 1 685902-06-01 - - - -26 Connector, Tubing 1 675027-65 2 204887-10-06-56 - -27 Adapter, Pipe - - 2 675029-01 - -Repair Kit 2164148-01 2164148-03 2164148-02*The 7-1/16” tandem booster is a part of the standard land and platform shear configuration for 7-1/16” U BOPs.**One assembly includes two tandem boosters.TC1001 25 © <strong>2002</strong> Cooper Cameron, Cameron Division

Tandem Boosters for U BOPs942481061312SD 03459157233111514162171Item Number Description Qty11” 15,000 psi13-5/8” 3000, 5000 and 10,000 psi** Tandem Booster Assembly 1 2010886-011 Adapter Plate 2 2010885-012 Pipe Plug 2 2010881-013 Cylinder 2 2010884-014 Cylinder Head 2 2010882-015 Tail Rod 2 2010880-016 Piston 2 645172-037 Screw Cap 16 702585-31-00-308 Screw Cap 12 702585-34-01-649 O-Ring 2 702645-33-7110 Seal, Lip 2 212641-34-00-0111 O-Ring 2 702645-38-1212 Seal Ring 2 71041813 Wear Ring 2 645215-0114 Wear Ring 2 049223-0115 Seal Ring 2 70477216 Filter, Quiet Muffler 2 272404217 Stud, Double Ended 2 702533-09-10-2218 Connector, Tubing 2 204887-10-06-5719 Cross 1 675029-2320 Nipple, Pipe 1 685902-07-00-3021 Hose Assembly 2 272453822 Connector, Tubing 2 -23 Gland, Tubing 2 017454-0824 Blind Plug 2 017454-0925 Elbow 2 71440726 Pipe Plug 2 002504-28- Repair Kit - 2164148-02**One assembly includes two tandem boosters.TC1001 26 © <strong>2002</strong> Cooper Cameron, Cameron Division

UM BOPsThe Cameron UM BOP is a lightweight blowout preventer designed for easy maintenanceand long life. The UM complements the existing line of U preventers with interchangeablebonnets that can be installed on any comparable size U BOP. Theshearing capabilities of the UM BOP bonnet is comparable to a U BOP bonnet withtandem boosters installed. The UM utilizes an internal booster that results in a reducedweight and length for the preventer and eliminates the need for externalplumbing. The UM replaces the UL since the UM bonnet features full stroke operationthat allows for one-step ram removal.Other features of the UM BOP include:• Bonnet seal carrier is available to eliminate the need for high makeup torqueon bonnet bolts and nuts.• Same bonnet used for both shear and pipe rams. The internal shear boostercan be reversed to act as a stroke-limiting device.• Internal booster provides the force necessary for shearing pipe and at thesame time provides a reduced sealing force for long ram seal life.• Hydraulically operated locking mechanisms, wedgelocks, are available forsubsea applications.• Most operating system seals can be replaced with the bonnet in theram-change position without removing the bonnets.• UM utilizes the same rams as the U BOP.Other features include hydraulically opening bonnets, forged body and a wide selectionof rams to meet all applications.UM Blowout PreventerSD 034595TC1001 27 © <strong>2002</strong> Cooper Cameron, Cameron Division

StandardTandemPipeBonnetPipeBonnetClosePressureOpenPressureClosePressureOpenPressureShearBonnetShearBonnetUM BOP Open and Close Hydraulics(13-5/8” 10,000 Shown)SD 034582TC1001 28 © <strong>2002</strong> Cooper Cameron, Cameron Division

UM BOP Operating Data and Fluid RequirementsBore Sizeand WorkingPressure7-1/16” AllWP11” Except15,000 psi11” 15,000psi13-5/8”Except15,000 psi13-5/8”15,000 psiModel BGals to OpenPipe Rams(1 set)Gals to ClosePipe Rams(1 set)Gals to CloseShear Rams(1 set)Closing Area(Sq. inches)Locking ScrewTurns(Each End)ClosingRatioOpeningRatio2.2 2.3 2.4 67.3 18 11.7:1 3.8:16.2 6.2 7.4 113.8 27 13.7:1 3.7:1- - - - - - -7.5 7.5 8.8 110.15 32 8.7:1 2.3:1- - - - - - -UM BOP Tandem Booster Operating Data and Fluid Requirements*Bore Sizeand WorkingPressure7-1/16” AllWP11” Except15,000 psi11” 15,000psi13-5/8”Except15,000 psi13-5/8”15,000 psiModel BGals to OpenShear Rams(1 set)Gals to CloseShear Rams(1 set)Closing Area(Sq. inches)Locking ScrewTurns(Each End)Closing RatioOpening Ratio- - - - - 3.8:17.4 13.1 201.8 27 24.3:1 3.7:1- - - - - -8.8 11.72 198 32 15.6:1 2.3:1- - - - - -*All volumes based on shear ram configurationTC1001 29 © <strong>2002</strong> Cooper Cameron, Cameron Division

TC1001 30 © <strong>2002</strong> Cooper Cameron, Cameron Division

UM BOP Specifications and DimensionsThe capital letters in the following designations refer to the UM BOP dimensional viewsand dimensional chart shown below .A-1 Length - bonnets closed, locking screws lockedA-2 Length - bonnets opened, locking screws unlockedB-1 Height - flangedB-2 Height - studdedC Width - no side outletsD Centerline of preventer to outlet flange or hub face. This distance is variableand must be determined per individual specifications.E Centerline of side outlet to bottom flange faceF Top of ram to top flange faceG Height of ramACDFBGESD 034610Single Open-Face Flange or Studded UM BOP Dimensions*SizePressureRating(psi)Vertical Bore(in)A-1 A-2 B-1 B-2 C E F GApprox.Weight (lb.)FlgXFlgApprox.Weight (lb.)StdXStd7-1/16” 3000 7-1/16 78.250” 116.500” 24.062” 17” 20.250” 8.750” 7.844” 5.50” 2600 24777-1/16” 5000 7-1/16 78.250” 116.500” 27.500” 16.75” 20.250” 10.406” 9.625” 5.50” 2652 24777-1/16” 10,000 7-1/16 78.250” 116.500” 30.562” 15.50” 20.625” 11.062” 12.031” 5.50” 3275 28257-1/16” 15,000 7-1/16 78.250” 116.500” 31.812” 15.50” 20.625” 11.688” 12.656” 5.50” 3525 282511” 10,000 11 96.250” 146.875” 35.688” 16.63” 25.750” 13.125” 13.844” 6.75” 6400 590013-5/8” 10,000 13-5/8 134.500” 201.000” 41.688” 20.26” 30.250” 15.125” 17.094” 7.50” 10,300 9650*Available with Stud x Flange ConnectionsTC1001 31 © <strong>2002</strong> Cooper Cameron, Cameron Division

UM BOP Specifications and DimensionsThe capital letters in the following designations refer to the UM BOP dimensional viewsand dimensional chart shown below.A-1 Length - bonnets closed, locking screws lockedA-2 Length - bonnets opened, locking screws unlockedB-1 Height - flangedB-2 Height - studdedB*** Height - with 30” spacerC Width - no side outletsD Centerline of preventer to outlet flange or hub face. This distance is variable andmust be determined per individual specifications.E Centerline of side outlet below rams to bottom flange faceF Top of upper ram to top flange faceG Height of ramH Centerline of side outlet between rams to bottom flange faceJ Top of lower ram to bottom of upper ramACDFGBJEHSD 034560Double Open-Face Flange or Studded UM BOP Dimensions*SizePressureRating(psi)Vertical Bore(in.)A-1 A-2 B-1 B-2 B*** C E F G H JApprox.Weight(lb.)FlgXFlgApprox.Weight(lb.)StdXStd7-1/16” 3000 7-1/16 78.250” 116.500” 41.000” 34” 18.562” 20.250” 8.750” 7.844” 5.50” 25.688” 11.438” 5100 49507-1/16” 5000 7-1/16 78.250” 116.500” 44.188” 33.50” 18.812” 20.250” 10.406” 9.625” 5.50” 27.094” 11.188” 4904 47297-1/16” 10,000 7-1/16 78.250” 116.500” 48.625” 31.50” 17.438” 20.625” 11.062” 12.031” 5.50” 29.125” 12.562” 5850 55007-1/16” 15,000 7-1/16 78.250” 116.500” 49.875” 33.50” 17.438” 20.625” 11.688” 12.656” 5.50” 29.750” 12.562” 6100 550011” 10,000 11 96.250” 146.875” 55.875” 36.44” 16.562” 25.750” 13.125” 13.844” 6.75” 33.312” 13.438” 11,300 11,30013-5/8” 10,000 13-5/8 134.500” 201.000” 66.625” 41.26” 12.562” 30.250” 15.125” 17.094” 7.50” 40.062” 17.438” 20,388 17,612*Available with Stud x Flange ConnectionsTC1001 32 © <strong>2002</strong> Cooper Cameron, Cameron Division

UM BOP Specifications and DimensionsThe capital letters in the following designations refer to the UM BOP dimensional viewsand dimensional chart shown below.A-1 Length - bonnets closed, locking screws lockedA-2 Length - bonnets opened, locking screws unlockedB-1 Height - flangedB-2 Height - studdedC Width - no side outletsD Centerline of preventer to outlet flange or hub face. This distance is variable andmust be determined per individual specifications.E Centerline of side outlet to bottom flange faceF Top of ram to top flange faceG Height of ramACDFGBESD 034612Single UM BOP with Tandem Boosters Dimensions*SizePressureRating(psi)Vertical Bore(in)A-1 A-2 B-1 B-2 C E F GApprox.Weight(lb.)FlgXFlgApprox.Weight(lb.)StdXStd13-5/8” 10,000 13-5/8” 169.125” 235.875” 41.688” 30.88” 30.50” 15.125” 17.094” 7.5” 11,600 11,000*Available with Stud x Flange ConnectionsTC1001 33 © <strong>2002</strong> Cooper Cameron, Cameron Division

37356343312331222640343353920382427282934334376352544121311 10 511514176766535256365021918162154551UM BOP, 7-1/16”SD 034510TC1001 34 © <strong>2002</strong> Cooper Cameron, Cameron Division

7-1/16” UM BOP Part NumbersItem No. Description Qty - Single Qty - Double7-1/16”5000 psiModel II7-1/16”10,000 psiModel II7-1/16”15,000 psiModel II1 Body 1 1 ---- ---- ----2 Bonnet 2 4 2010585-01 2010584-01 2010515-033 Operating Piston 2 4 2010559-02 2010559-01 2010559-014 Ram Change Piston, Open 2 4 2011075-01 2011075-01 2011075-015 Ram Change Piston, Close 2 4 2011073-01 2011073-01 2011073-016 Ram Change Cylinder 4 8 2011074-01 2011074-01 2011074-0110 Pin, Ram Guide 4 8 030313-02 030313-02 030313-0211 Check Valve 2 4 M517988 M517988 M51798812 Screw, Socket Head Set 2 4 005940-09 005940-09 005940-0913 Pipe Plug, Heavy Hex Head 2 4 005930-05-10 005930-05-10 005930-05-10*14 Retainer Ring, Plastic Packing 2 4 2010178-01 2010178-01 2010178-01*15 Energizing Ring 2 4 018586-12 018586-12 018586-12*16 Lip Seal 2 4 212741-37 212741-37 212741-37*17 O-Ring 2 4 018492-92 018492-92 018492-9218 Retainer, Lip Seal 2 4 689523-04 689523-04 689523-0419 Retaining Ring, Spirolox 2 4 018572-83 018572-83 018572-8320 Locking Screw 2 4 2010519-01 2010519-01 2010519-0121 Ring Gasket 4 8 ---- 021792-21 ----22 Locking Screw Housing 2 4 2010530-01 2010530-01 2010530-0123 Operating Cylinder 2 4 2010529-02 2010529-02 2010529-0224 Cylinder Head Weldment 2 4 2011328-01 2011328-01 2011328-0125 Stud, Double Ended 8 16 2010189-19 2010189-19 2010189-1926 Nut, Heavy Hex 8 16 2709000-13-01 2709000-13-01 2709000-13-01*27 Seal Ring 2 4 2708749-01 2708749-01 2708749-0128 Retainer Ring, Tail Rod 2 4 2010527-01 2010527-01 2010527-0129 Retaining Ring, Spirolox 2 4 041008-02-93-32 041008-02-93-32 041008-02-93-32*30 Seal Ring 2 4 2710280 2710280 2710280*31 O-Ring 4 8 702645-37-61 702645-37-61 702645-37-61*32 O-Ring 2 4 702645-26-91 702645-26-91 702645-26-91*33 Seal RIng 4 8 2724047 2724047 272404734 Wear Ring, Ram Change Piston 4 8 049223-28 049223-28 049223-28*35 O-Ring 8 16 702645-33-71 702645-33-71 702645-33-71*36 O-Ring 4 8 702645-32-81 702645-32-81 702645-32-81*37 O-Ring 8 16 702645-32-41 702645-32-41 702645-32-4138 Stud, Double Ended 16 32 219065-08-03-61 219065-08-03-61 219065-08-03-6139 Nut, Heavy Hex 16 32 2709000-08-01 2709000-08-01 2709000-08-0140 Lifting Eye 4 8 011849 011849 01184941 Split Retainer Ring 2 4 2010599-01 2010599-01 2010599-0142 Concentric Booster Ring 2 4 2010600-01 2010600-01 2010600-01*43 Seal Ring 2 4 710541 710541 710541*44 Plastic Packing 10 20 007650-08 007650-08 007650-0846 Blind Plug 4 8 017454-09 ---- 017454-0947 Pipe Plug 4 8 002504-04 ---- 002504-0448 Tubing Gland 4 8 017454-08 ---- 017454-0866 Name Plate 1 1 2032175-03 2032175-01 ----67 Name Plate 1 ---- 025950 025950 ----50 Bonnet Bolt 8 16 2010514-02 2010514-03 ----51 Bonnet Seal (Carrier Type) 4 8 ---- ---- ----51A Bonnet Seal (Face Type) 2 4 644197-01-00-01 644197-01-00-01 644197-01-00-0152 Stud, Double Ended 12 ---- ---- 219067-14-07-41 ----53 Nut, Heavy Hex 12 ---- ---- 2709000-14-01 ----54 Stud, Double Ended ---- ---- ---- ---- ----55 Nut, Heavy Hex ---- ---- ---- ---- ----56 Name Plate 1 1 ---- 236606-01 ----66 Name Plate 1 1 2032175-03 2032175-01 ----67 Name Plate 1 1 025950 025950 ----Accessory ItemsRam Change Piston Cover 2 4 645046-17 645046-17 645046-17Standard Accessory Items 1 1 697149-01 697149-02 697149-02Locking Screw Accessory Items 2 4 ---- 697150-01 697150-01Expendable ItemsRing Gasket 2 4 70<strong>2002</strong>-03-52 702003-15-22 702003-15-22Ring Gasket 2 4 70<strong>2002</strong>-04-62 702003-15-62 702003-15-62*These items included in Bonnet Rebuild Kit P/N 2010733-01. Two required for single, Four required for double.TC1001 35 © <strong>2002</strong> Cooper Cameron, Cameron Division

3533621232122263832285303313228435633173720362486 8725 40 422781062151417341115274 41 29121319181643UM BOP, 11”SD 034498TC1001 36 © <strong>2002</strong> Cooper Cameron, Cameron Division

11” UM BOP Part NumbersItem No. Description Qty - Single Qty - Double11”3000 psi11”5000 psi11”10,000 psi1 Body 1 1 ---- ---- ---- ----2 Bonnet (Seal Carrier) 2 4 ---- ---- ---- ----2A Bonnet (Face Seal) 2 4 ---- 2011152-01 2164126-01 ----3 Piston Subassembly 2 4 ---- 2011173-01 2011173-01 ----4 Ram Change Piston - Open 2 4 ---- 2011155-01 2011155-01 ----4A Ram Change Piston - Open, Special ---- ---- ---- ---- ---- ----5 Ram Change Piston - Close 2 4 ---- 2011144-01 2011144-01 ----5A Ram Change Piston - Close, Special ---- ---- ---- ---- ---- ----6 Ram Change Cylinder 4 8 ---- 2011154-01 2011154-01 ----8 O-Ring ---- ---- ---- ---- ---- ----9 Ram Change Piston Cap ---- ---- ---- ---- ---- ----10 Ram Guide Pin 4 8 ---- 030313-03 030313-03 ----11 Check Valve 2 4 ---- M517988 M517988 ----12 Set Screw, Socket Head 2 4 ---- 005940-09 005940-09 ----13 Pipe Plug 2 4 ---- 005930-05-10 005930-05-10 ----*14 O-Ring 2 4 ---- 2010178-02 2010178-02 ----*15 Energizing Ring 2 4 ---- 018586-13 018586-13 ----*16 Lip Seal 2 4 ---- 212741-38-00-01 212741-38-00-01 ----*17 O-Ring 6 12 ---- 018492-91 018492-91 ----18 Retainer, Lip Seal 2 4 ---- 689523-05 689523-05 ----19 Retaining Ring, Spirolox 2 4 ---- 018572-84 018572-84 ----20 Locking Screw 2 4 ---- 046628-01 046628-01 ----*21 O-Ring 4 8 ---- 702645-38-21 702645-38-21 ----22 Locking Screw Housing 2 4 ---- 2011168-01 2011168-01 ----23 Operating Cylinder 2 4 ---- 2011172-01 2011172-01 ----24 Cylinder Head Weldment 2 4 ---- 2011167-01 2011167-01 ----25 Stud, Double Ended 8 16 ---- 219065-17-20-01 219065-17-20-01 ----26 Nut 8 16 ---- 2164777-01 2164777-01 ----*28 O-Ring 4 8 ---- 702645-33-31 702645-33-31 ----*29 Plastic Packing 10 20 ---- 007650-25 007650-25 ----*30 Seal Ring 2 4 ---- 2724061 2724061 ----31 Wear Ring 2 4 ---- 049223-31 049223-31 ----32 Wear Ring 4 8 ---- 049223-32 049233-32 ----*33 O-Ring 8 16 ---- 702645-33-91 702645-33-91 ----*34 O-Ring 4 8 ---- 702645-33-01 702645-33-01 ----*35 O-Ring 8 16 ---- 702645-32-61 702645-32-61 ----36 Stud, Double Ended 16 32 ---- 219065-12-05-01 219065-12-05-01 ----37 Nut 16 32 ---- 2709000-12-01 2709000-12-01 ----38 Lifting Eye 2 4 ---- 011849 011849 ----40 Blind Plug 4 8 ---- 017454-09 017454-09 ----41 Plug, Pipe, Threaded 4 8 ---- 002504-04 002504-04 ----42 Tubing Gland 4 8 ---- 017454-08 017454-08 ----*43 Ring Gasket 4 8 ---- 021792-22 021792-22 ----52 Bonnet Bolt 8 16 ---- 2010962-01 2164128-01 ----62 Bonnet Seal Carrier 2 4 ---- 645464-02-00-01 645464-02-00-01 ----62A Bonnet Seal (Face Type) 2 4 ---- 644197-02-00-01 644197-02-00-01 ----62B Bonnet Seal (Carrier Type) 2 4 ---- 645484-02-00-01 645484-02-00-0162C Retainer Ring (Use with Seal Carrier) 2 4 ---- 702645-27-61 702645-27-6174 O-Ring 8 16 ---- 702645-22-91 702645-22-91 ----78 Lifting Eye 2 2 ---- 011849 011849 ----96 Name Plate 1 1 ---- 2032175-03 2032175-03 ----97 Name Plate 1 1 ---- 025950 025950 ----Accessory ItemsStandard Accessories 1 1 ---- 697149-02 697149-02 ----Locking Screw Accessories 2 4 ---- 697150-02 697150-02 ----Cover, Ram Change Pistons 2 2 ---- 645046-18 645046-18 ----Expendable ItemsRing Gaskets (Top & Bottom Conn.) 2 2 ---- 70<strong>2002</strong>-05-42 702003-15-82 ----*These items included in Bonnet Rebuild Kit P/N 2010733-02. Two required for single, Four required for double.11”15,000 psiTC1001 37 © <strong>2002</strong> Cooper Cameron, Cameron Division

392220459835537 36 63631233138 1529330 50 33 11 43 40 2141214 43 43 40 16 19 17 18 51 343244241112575747642 41 10 78See Detail“A”428127141211Detail “A”66656471702632111243431214UM BOP, 13-5/8”SD034538TC1001 38 © <strong>2002</strong> Cooper Cameron, Cameron Division

13-5/8” UM BOP Part NumbersItem No. Description Qty - Single Qty - Double13-5/8”13-5/8”13-5/8”5000 psi10,000 psi15,000 psi1 Body 1 1 ---- ---- ----2 Bonnet (Seal Carrier) 2 4 ---- 2164340-01(02) ----2A Bonnet (Face Seal) 2 4 ---- 2164343-01(02) ----3 Piston Subassembly (2) (4) ---- 2164345-01 ----4 Ram Change Piston - Open 2 4 ---- 2164433-02 ----4A Ram Change Piston - Open, Special 2 4 ---- 2164433-01 ----5 Ram Change Piston - Close 2 4 ---- 2164434-02 ----5A Ram Change Piston - Close, Special 2 4 ---- 2164434-01 ----6 Ram Change Cylinder 4 8 ---- 2164347-02 ----6A Ram Change Cylinder, Special 4 8 ---- 2164347-01 ----*8 O-Ring 4 8 ---- 702645-35-71 ----9 Ram Change Piston Cap 4 8 ---- 2164342-02 ----9A Ram Change Piston Cap, Special 4 8 ---- 2164342-01 ----10 Ram Guide Pin 4 8 ---- 030313-01 ----11 Retainer Ring, Spirolox, Operating Piston 8 16 ---- 708758 ----12 Retainer, Polypak 8 16 ---- 689523-06 ----*14 Seal Polypak 8 16 ---- 2724613-01 ----*15 Wear Ring, Ram Change Piston 4 8 ---- 2164449-01 ----16 Check Valve 2 4 ---- M517988 ----17 Screw, Socket Head 2 4 ---- 005940-09 ----18 Pipe Plug 2 4 ---- 005930-05-10 ----*19 Packing, Plastic 2 4 ---- 007650-25 ----20** Locking Screw 2 4 ---- 695234 ----22** Locking Screw Housing 2 4 ---- 2164346-01 ----23 Operating Cylinder 2 4 ---- 2164348-02 ----23 Operating Cylinder, Special 2 4 ---- 2164348-01 ----24 Cylinder Head 2 4 ---- 2164341-02 ----24 Cylinder Head, Special 2 4 ---- 2164341-01 ----25 Cylinder Stud 24 48 ---- 2164361-01 ----26 Nut, Cylinder 24 48 ---- 2709000-12-22 ----*27 Retainer Ring, Plastic Packing 2 4 ---- 012469-24 ----*28 Energizing Ring 2 4 ---- 018586-01 ----*29 Wear Ring, Operating Piston 2 4 ---- 049223-31 ----*30 Seal Ring 2 4 ---- 2724061 ----*31 O-Ring 4 8 ---- 702645-38-21 ----32 Washer, Cylinder Stud 24 48 ---- K220607 ----33 Washer, Bonnet Bolt 8 16 ---- 2164450-01 ----*35 O-Ring 4 8 ---- 702645-33-81 ----*36 O-Ring 8 16 ---- 702645-34-61 ----*37 O-Ring 8 16 ---- 702645-32-41 ----37A O-Ring, Special for V Threaded Ram Change Piston 8 16 ---- 702645-32-81 ----*38 O-Ring 4 8 ---- 702645-33-31 ----39** Screw 16 32 ---- 702585-25-00-30 ----40 Lifting Eye 4 8 ---- 011849 ----41 Tubing Gland 4 8 ---- 017454-08 ----42 Blind Plug 4 8 ---- 017454-09 ----43 Pipe Plug, Pressure 12 24 ---- 002504-14 ----45 Pipe Plug, Threaded 4 8 ---- 203682 ----50 Bonnet Bolt 8 16 ---- 2164362-01 ----*51 O-Ring 8 16 ---- 2164718-01 ----64 Name Plate 1 1 ---- 025950 ----65 Name Plate 1 1 ---- 2032175-03 ----66 Name Plate 1 1 ---- 236606-01 ----70 Lifting Lug 2 2 ---- 2164420-01 ----71 Screw, Cap 8 8 ---- 702546-31-00-34 ----74 Stud, Top End Connection 20 20 ---- 219065-17-10-71 ----75 Nut, Top End Connection 20 20 ---- 2709000-17-01 ----76 Pipe Plug 2 4 ---- 201019 ----77 Bonnet Seal Carrier 2 4 ---- 645507-01-00-01 ----78 Bonnet Seal (for Carrier) 4 8 ---- 645509-01-00-01 ----78A Bonnet Seal (Face Type) (2) (4) ---- 644197-03-00-01 ----78B Retainer Ring (Use with Seal Carrier) 2 4 ---- 702645-27-9179 O-Ring 2 4 ---- 702645-56-91 ----80*** Tandem Booster Assembly (Qty. 1 for 2 Bonnets) 1 1 ---- 2164649-01 ----Accessory ItemsStandard Accessories 1 1 ---- 697149-12 ----Locking Screw Accessories 2 4 ---- 697150-02 ----Spanner Wrench 1 1 ---- 2164429-01 ----Expendable ItemsRing Gaskets (Top & Bottom Connection) 2 2 ---- 702003-15-92 ----Eyebolt 2 2 ---- 700734 ----Paste 1 1 ---- 705444 ----Loctite Adhesive 1 1 ---- 708740 ----Thread Sealant 1 1 ---- 711706 ----*These items included in Bonnet Rebuild Kit P/N 2010733-03. Two required for single, Four required for double.**Not Required When Using Wedgelocks or Tandem Boosters***Optional Tandem BoostersTC1001 39 © <strong>2002</strong> Cooper Cameron, Cameron Division

Minimum Shearing Configurations for the UM BOPAPI Designated Size Ram Type Pressure Rating (psi) Pipe OD (In.) Pipe lb/ft Pipe Grade Shearing Configuration7-1/16” SBR All 3-1/2 13.3 S Standard Bonnets11” SBR 10,000 and Lower 5 19.5 E Shear Bonnets with Tandem Boosters11” DS 10,000 and Lower 5 19.5 E Standard Bonnets13-5/8” SBR 10,000 and Lower 5 19.5 G Standard Bonnets13-5/8” DS 10,000 and Lower 5 19.5 G Standard BonnetsNote: See page 41 for a complete list of part numbers for the tandem boosters.161771512131415631123249108254282730292629Tandem Booster AssemblySD 034536TC1001 40 © <strong>2002</strong> Cooper Cameron, Cameron Division

Tandem Boosters for UM BOPsA BOP equipped with tandem boosters can deliver increased shearing force whilenot increasing the wear and tear on the packers. Tandem boosters approximatelydouble the force available to shear pipe. Since the tailrod of the tandem booster hasthe same stroke as the BOP’s operating piston, the standard shear locking mechanismcan be installed on the outside end of the booster.For information concerning applications where a tandem booster is required, consultyour Cameron representative.13-5/8” 10,000 psi WP UM Tandem BoosterItem Number Description Qty.1 Adapter 2 2164650-01Part Number13-5/8” 10,000 psi WP3 Cylinder 2 2010884-014 Cylinder Head 2 2010882-025 Tail Rod 2 2010880-016 Piston 2 645172-037 Screw, 12 Pt Cap 16 702585-25-00-308 Screw, 12 Pt Cap 12 702585-34-01-549 O-Ring 2 702645-33-7110 Seal, Lip 2 011741-3411 O-Ring 2 702645-38-1212 Seal Ring 2 71041813 Wear Ring 2 645215-0114 Wear Ring 2 049223-0115 Seal Ring 2 70477216 Filter, Muffler, Quiet Flow 2 272404217 Stud, Continuous Thread 2 702533-09-10-2223 Gland, Tubing 2 017454-0824 Blind Plug 2 017454-0925 Plug, Pipe-Threaded Hex Socket 2 002504-2826 Tubing, Hydraulic 2 2711865-12-1127 Bushing, Pipe 2 K19448928 Bushing, Pipe 2 20309829 Connector, Tubing, Male 4 204887-08-05-1730 Elbow, 90 Degree, Male 2 204890-08-05-17TC1001 41 © <strong>2002</strong> Cooper Cameron, Cameron Division

U and UM BOP Standard AccessoriesU and UM BOP Standard AccessoriesSize and Working PressureRamLube*CameronBox Wrench*Allen Wrench*Packing Screw Handwheel** UniversalJoint**ExtensionWrench*7-1/16” 3000 psi 713878 713114-08 008721-01 005457 006018-01 0056527-1/16” 5000 psi 713878 713114-08 008721-01 005457 006018-01 0056527-1/16” 10,000 & 15,000 psi 713878 713114-10 008721-01 005457 006018-01 00565211” 3000, 5000 & 10,000 psi 713878 713114-10 008721-01 005298 006018-03 00552611” 15,000 psi 713878 713114-13 008721-01 005298 006018-03 00552613-5/8” 3000 & 5000 psi 713878 713114-10 008721-01 005298 006018-03 00552613-5/8” 10,000 psi 713878 713114-13 008721-01 005298 006018-03 00552613-5/8” 15,000 psi 713878 *** 008721-01 005298 006018-03 00552616-3/4” 3000 & 5000 psi 713878 713114-13 008721-01 005298 006018-03 00552616-34/4” 10,000 psi 713878 *** 008721-01 005298 006018-03 00552618-3/4” 10,000 psi 713878 *** 008721-01 005298 006018-03 00552620-3/4” 3000 psi 713878 713114-08 008721-01 005298 006018-03 00552621-1/4” 2000 psi 713878 713114-10 008721-01 005298 006018-03 00552621-1/4” 5000 psi 713878 *** 008721-01 005298 006018-03 00552621-1/4” 10,000 psi 713878 *** 008721-01 005298 006018-03 00552626-3/4” 3000 psi 713878 713114-13 008721-01 005298 006018-03 005526*One required.**Two required for single preventer, four for double preventer.*** Commercially available sockets are recommended.TC1001 42 © <strong>2002</strong> Cooper Cameron, Cameron Division

U, UL and UM BOP Pipe RamsPipe rams are available for use in Cameron U, UL and UM BOPs to fit all commonly usedsizes of tubing, drill pipe, drill collar or casing within the ranges in the charts on the followingpages. Cameron pipe rams include the following features:• Cameron pipe rams are self-feeding and incorporate a large reservoir ofpacker rubber to ensure a long-lasting seal under all conditions.• Ram packers lock into place and are not dislodged by well flow.• All Cameron pipe rams are suitable for H 2 S service per NACE MR-01-75.• CAMRAM top seals are standard for all U, UL and UM BOP pipe rams from7-1/16” through 18-3/4” sizes. Packer part numbers beginning with 644xxxindicate the CAMRAM lipped-plate design. Other part numbers may usestandard elastomer material and reinforced plates. Verify this with yourCameron representative.CAMRAM 350 packers and top seals are available for high temperature service and forservice in which concentrations of H 2 S are expected.U, UL and UM BOP Pipe RamTC1001 43 © <strong>2002</strong> Cooper Cameron, Cameron Division

Part Numbers for U, UL & UM BOP Pipe RamsPipe Size(in.)7-1/16”3000, 5000, 10,000, and 15,000 psi WPTop Seal 644214-01-00-0111”3000, 5000, and 10,000 psi WPTop Seal 644217-01-00-0111”15,000 psi WPTop Seal 2010453-0113-5/8”3000, 5000, and 10,000 psi WPTop Seal 644223-01-00-01Assembly Ram Packer Assembly Ram Packer Assembly Ram Packer Assembly Ram PackerBlind 644504-01 644500-01-00-02 644215-01-00-01 644219-01 044118-01 644218-01-00-01 644222-01 044121-01 644221-01 644225-01 044147-01-00-01 644224-01-00-011.050 644504-02 644501-01 644215-02 - - - - - - - - -1.315 644504-03 644501-02 644215-03 044233-25 044118-07 019243-08 - - - 644225-02 044148-06 644224-021.660 644504-04 644501-03 644215-04-00-01 044233-02 044118-02 019243-06 644222-02 044121-02 644221-02 644225-03 044148-05 644224-031.900 644504-05 644501-04 644215-05-00-01 044233-03 044118-03 019243-05 644222-03 044121-03 644221-03 644225-04 044148-07 644224-042.062 644504-06 644501-05 644215-06 044233-04 044118-04 019243-04 644222-04 044121-04 644221-04 644225-05 044148-03 644224-052.375 644504-07 644501-06 644215-07-00-01 644219-06 044118-05 644218-06-00-01 644222-05 044121-05 2010454-05 644225-06 044148-01-00-01 644224-06-00-012.875 644504-08 644501-07 644215-08-00-01 644219-07 044118-06 644218-07-00-01 644222-06 044121-06 2010454-06 644225-07 044148-02-00-01 644224-07-00-013.500 644504-09 644502-01-00-01 644215-09-00-01 644219-08 644835-01-00-02 644218-08-00-01 644222-07 644753-01 2010454-07 644225-08 644738-01-00-01 644224-08-00-014.000 644504-11 644503-02 644215-11-00-01 644219-10 044119-02 644218-10-00-01 044234-10 044122-04 644218-13 644225-10 044149-02 644224-10-00-014.500 644504-12 644503-03 644215-12-00-01 644219-11 644835-02 644218-11-00-01 644222-09 644753-02 2010454-09 644225-11 644738-02 644224-11-00-014.750 - - - 044233-12 044119-04 644218-13 - - - 644225-13 044150-01 644224-135.000 644504-14 644503-05 644215-14-00-01 644219-14 644835-03-00-01 644218-14-00-01 644222-10 644753-03 2010454-10 644225-14 644738-03-00-01 644224-14-00-015.500 644504-15 644503-06 644215-15-00-01 644219-16 044120-01 644218-16-00-01 044234-13 044123-01 2010454-11 644225-16 044150-03 644224-16-00-015.750 - - - 044233-23 044120-10 644218-17 - - - - - -5.875 - - - - - - - - - 644225-30 644738-06-00-01 644224-29-00-016.000 - - - 044233-16 044120-02 644218-18-00-01 044234-14 044123-02 690808-13 044244-13 044150-04 644224-176.625 - - - 044233-17 644835-04 644218-19-00-01 044234-15 044123-03 690808-14 644225-18 644738-04-00-02 644224-18-00-017.000 - - - 044233-18 044120-04 644218-20-00-01 044234-16 044124-01 2010454-14 644225-19 044151-01-00-01 644224-19-00-017.625 - - - 044233-19 044120-05 644210-21-00-01 044234-17 044124-02 690808-16 644225-20 044151-02 644224-20-00-017.750 - - - 044233-22 044120-09 644218-22-00-01 - - - 044244-25 044151-06 644224-218.625 - - - 044233-20 044120-06 644218-23-00-01 - - - 044244-16 044151-03 644224-229.000 - - - - - - - - - 044244-24 044151-04 019506-069.625 - - - - - - - - - 644225-24 044151-05-00-01 644224-24-00-0110.750 - - - - - - - - - 644225-25 044152-01 644224-25-00-0111.750 - - - - - - - - - 044244-26 614208-01 644224-26-00-013.500Aluminum4.500Aluminum5.000Aluminum644504-10 644503-01 644215-10 044233-08 044119-06 644218-09 - - - 044244-20 044149-04 644224-09644504-13 644503-04 644215-13 044233-11 044119-07 644218-12 - - - 044244-10 044149-05 031215-17- - - 044233-24 044119-08 644218-15 - - - 044244-32 044150-08 031215-27TC1001 44 © <strong>2002</strong> Cooper Cameron, Cameron Division

Part Numbers for U, UL & UM BOP Pipe RamsPipe Size(in.)13-5/8”15,000 psiTop Seal 644226-01-00-0116-3/4”3000, 5000, and 10,000 psiTop Seal 644229-01-00-0118-3/4”10,000 psiTop Seal 644232-01-00-0121-1/4”5000 and 10,000 psiTop Seal 2010939-01Assembly Ram Packer Assembly Ram Packer Assembly Ram Packer Assembly Ram PackerBlind 644228-01 044143-01 644227-01-00-01 644231-01 044179-01 644230-01-00-01 644234-01 044184-01 644233-01 044262-01 044214-01 2010851-191.050 - - - - - - - - - - - -1.315 - - - - - - - - - - - -1.660 - - - - - - - - - - - -1.900 - - - 644231-02 044180-03 644230-02-00-01 - - - - - -2.062 044243-02 044144-03 040910-20 - - - - - - - - -2.375 644228-03 044144-01 644227-03-00-01 644231-03 044180-01 644260-03 044254-02 044185-01 644233-02 044262-02 044215-01 2010851-012.875 644228-04 044144-02 644227-04-00-01 644231-04 044180-02 644230-04 044254-03 044185-02 644233-03 044262-03 044215-02 2010851-023.500 644228-05 644739-01 644227-05-00-01 644231-05 644740-01 644230-05-00-01 644234-04 644741-01 644233-04-00-01 44262-04 644743-01 2010851-034.000 644228-07 044144-06 644227-07 644231-06 044181-02 644230-06 044254-06 044185-05 644233-06 044262-06 044215-05 040962-044.500 644228-08 644739-02 644227-08-00-01 644231-07 644740-02 644230-07-00-01 044254-07 644741-02 644233-07 044262-07 644743-02 2010851-054.750 044243-10 044145-01 040910-07 644231-08 044181-04 644230-08-00-01 044254-09 044185-08 041856-06 044262-09 044215-08 040962-065.000 644228-11 644739-03 644227-11-00-01 644231-09 644740-03 644230-09-00-01 644234-10 644741-03 644233-10-00-01 044262-10 644743-03 2010851-075.500 044243-12 044145-03 644227-12-00-01 644231-10 044181-06 644230-10-00-01 044254-11 044185-10 644233-11 044262-11 044215-10 2010851-085.750 - - - - - - - - - - - -5.875 2164172-07 2724029-06 644227-24-00-01 644231-22 2724030-06 644230-23 644234-21 2724031-06 644233-21-00-01 044262-32 2724033-06 2010851-296.000 044243-14 044145-04 040910-09 644231-11 049291-01 644230-11 044254-13 044185-12 041856-09 044262-13 044215-12 040962-096.625 044243-15 644739-04 644227-14 644231-12 049291-02 644230-12 044254-14 044185-13 644233-13 044262-14 044215-13 2010851-107.000 044243-16 044146-01 644227-15-00-01 644231-13 049291-03 644230-13 044254-15 044185-14 644233-14 044262-15 044215-14 2010851-117.625 044243-17 044146-02 644227-16-00-01 644231-14 049291-04 644230-14 044254-16 044185-15 041856-12 044262-16 044215-15 040962-127.750 044243-22 044146-07 644227-17 - - - - - - - - -8.625 044243-18 044146-03 040910-13 644231-15 049291-06 644230-15-00-01 044254-17 044185-16 041856-13 044262-17 044215-16 040962-139.000 044243-19 044146-04 040910-14 644231-16 049291-07 644230-16-00-01 044254-18 044185-17 041856-14 044262-18 044215-17 040962-149.625 044243-20 044146-05 644227-20-00-01 644231-17 049292-01 644230-17-00-01 044254-19 044185-18 644233-18 044626-19 044215-18 040962-1510.750 044243-21 044146-06 644227-21-00-01 644231-18 049292-02 644230-18-00-01 044254-21 044185-21 644233-19 044262-20 044216-01 040962-2011.750 - - - 644231-19 049292-03 644230-19-00-01 - - - 044262-21 044216-02 2010851-2013.375 - - - 644231-20 049292-04 644230-20-00-01 044254-22 044185-20 644233-20 044262-22 044216-03 2010851-2213.625 - - - - - - - - 044262-24 044216-05 040962-2413.750 - - - - - - - - - - - -16.000 - - - - - - - - - 044262-23 044216-04 2010851-233.500Aluminum4.500Aluminum5.000Aluminum044243-06 044144-05 644227-06 - - - 044254-05 044185-04 041856-16 044262-05 044215-04 040962-16044243-08 044144-08 040910-05 - - - 044254-08 044185-07 041856-17 044262-08 044215-07 040962-17- - - - - - - - - - - -TC1001 45 © <strong>2002</strong> Cooper Cameron, Cameron Division

Part Numbers for U, UL & UM BOP Pipe RamsPipe Size(in.)21-1/4” Bore 2000 psi20-3/4” Bore 3000 psiTop Seal 2163621-0126-3/4” Bore2000 and 3000 psiTop Seal 2163566-01Assembly Ram Packer Assembly Ram PackerBlind 044256-01 044191-01 2163612-01 044260-01 044209-01 2163561-011.050 - - - - - -1.315 - - - - - -1.660 - - - - - -1.900 - - - - - -2.062 - - - - - -2.375 - - - 044260-02 614017-01 2163559-012.875 - - - 044260-03 614017-02 2163559-023.500 044256-02 645328-01 2163613-03 044260-04 614018-01 2163599-034.000 044256-03 044192-02 031228-04 044260-05 614018-02 2163599-044.500 044256-04 645328-02 2010583-05 044260-06 614018-03 2163599-054.750 044256-05 044192-04 031228-06 - - -5.000 044256-06 645328-03-00-01 2163613-06 044260-07 614018-04 2163599-065.500 044256-07 044193-02 2163613-07 044260-08 614018-05 2163599-075.750 - - - - - -5.875 044256-32-00-01 645328-05-00-01 2163613-18 - - -6.000 044256-08 044193-03 031228-09 044260-09 614019-01 2163559-086.625 044256-09 645328-04 2010583-10-01 044260-10 614019-02 2163559-097.000 044256-10 044193-05 031228-11 044260-11 614019-03 2163559-107.625 044256-11 044193-06 031228-12 044260-12 614019-04 2163559-017.750 - - - - - -8.625 044256-13 044193-08 031228-14 - - -9.000 044256-14 044193-09 031228-15 044260-14 614019-06 2163599-139.625 044256-15 044193-10 031228-16 044260-15 614020-01 2163599-1410.750 044256-16 044194-01 2010583-17 044260-16 614020-02 2163599-1511.750 044256-17 044194-02 031228-18 044260-17 614020-03 2163599-1613.375 044256-18 044194-03 2163613-15 044260-18 614020-04 2163599-1713.625 044256-21 044194-05 031228-24 - - -13.750 044256-19 044194-04 031228-19 - - -16.000 044256-20 044195-01 2010583-21 044260-19 614021-01 2163559-1818.625 044256-22 614459-01 031228-25 - - -20.000 - - - 044260-20 614021-02 2163559-21TC1001 46 © <strong>2002</strong> Cooper Cameron, Cameron Division

Hang-Off WeightsHang-off weights are estimated capacities with hardened top corners of the hang-off rams. This enablesthe rams to dig into the tool joint and provide superior hang-off capacity while still meetingNACE requirements.For variable bore rams (VBR’s) and FLEXPACKER rams hang-off data, refer to Cameron EngineeringBulletin 859D.Hang-Off Weights(See Cameron Engineering Bulletin 636)Pipe SizePipe Rams3-1/2” 425,000 lb4-1/2” 550,000 lb5” 600,000 lb5-1/2” 600,000 lb6-5/8” 600,000 lbU BOP Shearing Blind RamsCameron shearing blind rams shear the pipe in the hole, then bend the lower section of sheared pipeto allow the rams to close and seal. Shearing blind rams can be used as blind rams during normaldrilling operations.The DS shearing blind ram can cut large diameter tubulars or multiple tubing strings regardless oftheir orientation to the centerline of the ram. A blade seal between the upper and lower faces eliminatesthe need for moving pipe after shearing.Features of shearing blind rams and DS rams include:• Large frontal area on the blade face seal reduces pressure on the rubber and increases servicelife.• Cameron SBRs can cut pipe numerous times without damage to the cutting edge.• The single-piece body incorporates an integrated cutting edge.• CAMRAM TM top seals are standard for all U BOP shearing blind rams through 18-3/4”.• For U and UII BOPs through 18-3/4”, part numbers beginning with 644XXX indicate theCAMRAM lipped-plate design. Other part numbers may use standard elastomer material andreinforced plates. Verify this with your Cameron representative.• H 2 S SBRs are available for critical service applications and include a blade material ofhardened high alloy suitable for H 2 S service.TC1001 47 © <strong>2002</strong> Cooper Cameron, Cameron Division

Shearing Blind RamU, UL and UM BOP Shearing Blind Ram Part NumbersBOP Bore Size andWorking Pressure7-1/16” 5000,10,000, 15,000 psi1Upper Ram Subassy2Body*Description and Item Number3Blade Packer*4Side Packer*5Side Packer*046792-01-00-03 046210-01-00-04 - 2010873-02 2010873-0111” 5000, 10,000 psi 645011-03-00-01 645009-01-00-01 046910-04-00-01 046751-04-00-01 046752-04-00-0111” 15,000 psi 2010458-01 2010459-01 046910-04-00-01 2010460-07 2040461-0713-5/8” 5000,10,000 psi644781-01-00-01 644780-01-00-01 644435-01-00-01 046751-01-00-02 046752-01-00-0213-5/8” 15,000 psi 2163019-01-01 2163017-01-01 644435-01-00-01 046751-05-00-01 046752-05-00-0116-3/4” 5000 psi 046766-01-00-01 049006-01-00-01 046910-03-00-01 046751-03-00-01 046752-03-00-0116-3/4” 10,000 psi 046773-01-00-01 046774-01-00-01 046910-03-00-01 046751-03-00-01 046752-03-00-0118-3/4” 10,000 psi 2010186-01 2010187-01 2010192-01 2010191-01 2010190-0120-3/4” 3000 psi 046783-01-00-02 046784-01-00-02 - 615235-01-00-01 -21-1/4” 2000 psi 046783-01-00-02 046784-01-00-02 - 615235-01-00-01 -21-1/4” 5000 psi 049983-01 049961-01 046910-05-00-01 046751-06-00-01 046752-06-00-0121-1/4” 7500,10,000 psi046788-01 049012-01 046910-05-00-01 046751-06-00-01 046752-06-00-01BOP Bore Size andWorking Pressure7-1/16” 5000,10,000, 15,000 psi6Lower Ram Subassy**7BodyDescription and Item Number8Side Packer9Side Packer10Top Seal(2 Required)046792-02-00-03 046212-01-00-04 2010672-01 - 644214-01-00-0111” 5000, 10,000 psi 645011-04-00-01 645009-02-00-01 046751-04-00-01 046752-04-00-01 644217-01-00-0111” 15,000 psi 2010458-02 2010459-02 2010460-07 2010461-07 2010453-0113-5/8” 5000,10,000 psi644781-02-00-01 644780-02-00-01 046751-01-00-02 046752-01-00-02 644223-01-00-0113-5/8” 15,000 psi 2163019-02-01 2010292-01 046751-05-00-01 046752-05-00-01 644226-01-00-0116-3/4” 5000 psi 046766-02-00-01 049007-01-00-01 046751-03-00-01 046752-03-00-01 644229-01-00-0116-3/4” 10,000 psi 046773-02-00-01 046775-01-00-01 046751-03-00-01 046752-03-00-01 644229-01-00-0118-3/4” 10,000 psi 2010186-02 2010188-01 2010191-01 2010190-01 2010193-0120-3/4” 3000 psi 046783-02-00-02 046785-01-00-02 615247-01-00-01 615247-02-00-01 2163621-0121-1/4” 2000 psi 046783-02-00-02 046785-01-00-02 615247-01-00-01 615247-02-00-01 2163621-0121-1/4” 5000 psi 049983-02 049982-01 046751-06-00-01 046752-06-00-01 645478-01-00-0121-1/4” 7500,10,000 psi046788-02 049011-01 046751-06-00-01 046752-06-00-01 645478-01-00-01*Part of Upper Ram Assembly.TC1001 48 © <strong>2002</strong> Cooper Cameron, Cameron Division

H 2 S Shearing Blind RamU, UL and UM BOP H 2 S Shearing Blind Ram Part NumbersBOP Bore Sizeand WorkingPressure (psi)11” 5000 and10,0001Upper RamSubassy2Ram3Blade Packer4Packer5Packer6Top Seal7Blade Insert8Set Screw645011-03-00-01 645009-01-00-01 046910-04-00-01 046751-04-00-01 046752-04-00-01 644217-01-00-01 645010-01-00-01 644582-0113-5/8” 5000 and10,000644781-01-00-01 644780-01-00-01 644435-01-00-01 046751-01-00-02 046752-01-00-02 644223-01-00-01 644581-01-00-01 644582-0113-5/8” 15,000 2163019-01-01 2163017-01-01 644435-01-00-01 046751-05-00-01 046752-05-00-01 644226-01-00-01 216481-01 644582-0118-3/4” 10,000 2010186-01 2010187-01 2010192-01 2010191-01 2010190-01 2010193-01 2010182-01 644524-01BOP Bore Sizeand WorkingPressure (psi)11” 5000 and10,00013-5/8” 5000 and10,0009Lower RamSubassy10Ram11Packer12Packer13Top Seal14Blade Insert645011-04-00-01 645009-02-00-01 046751-04-00-01 046752-04-00-01 644217-01-00-01 645010-02-00-01 <strong>2002</strong>31644781-02-00-01 644780-02-00-01 046751-01-00-02 046752-01-00-02 644223-01-00-01 644581-02-00-01 <strong>2002</strong>3113-5/8” 15,000 2163019-02-01 2163018-01-01 046751-05-00-01 046752-05-00-01 644226-01-00-01 644581-02-00-01 <strong>2002</strong>3118-3/4” 10,000 2010186-02 2010188-01 2010191-01 2010190-01 2010193-01 2010183-01 <strong>2002</strong>3115PinSevere Service U, UL and UM BOP H 2 S Shearing Blind Ram Part NumbersBOP Bore Sizeand WorkingPressure (psi)13-5/8” 5000 and10,0001Upper RamSubassy2Ram3Blade Packer4Packer5Packer6Top Seal7Blade Insert8Set Screw644781-03-00-01 644780-01-00-01 644834-01-00-01 645427-01-00-01 645428-01-00-01 644707-01-00-01 644581-01-00-01 644582-0113-5/8” 15,000 2163019-01-02 2163017-01-01 644834-01-00-01 644832-01-00-01 644833-01-00-01 644709-01-00-01 2164281-01 644582-01BOP Bore Sizeand WorkingPressure (psi)13-5/8” 5000 and10,0009Lower RamSubassy10Ram11Packer12Packer13Top Seal14Blade Insert644781-04-00-01 644780-02-00-01 645427-01-00-01 645428-01-00-01 644707-01-00-01 644581-02-00-01 <strong>2002</strong>3113-5/8” 15,000 2163019-02-02 2163018-01-01 644832-01-00-01 644833-01-00-01 644709-01-00-01 644581-02-00-01 <strong>2002</strong>3115PinTC1001 49 © <strong>2002</strong> Cooper Cameron, Cameron Division

DS Shearing Blind RamU BOP DS Shearing Blind RamBOP Size andWorkingPressure (psi)11” 5000 and10,00013-5/8” 5000 and10,000BOP Size andWorkingPressure (psi)11” 5000 and10,00013-5/8” 5000 and10,0001Upper RamAssembly2*BodyDescription and Item Number3*SidePacker4*SidePacker5*BladeSeal6*BladeSeal645078-01-00-04 645079-01-00-04 645080-02-00-01 645080-01-00-01 645031-02-00-01 645031-02-00-01645026-01-00-04 645027-01-00-04 2010985-01 2010985-02 2010986-01 2010986-027Lower RamSubassembly8**Body9**SidePacker10**SidePacker11Top Seal(2 Required)645078-02-00-04 645079-02-00-04 645080-02-00-01 645080-01-00-01 644217-02-00-01645026-02-00-04 645027-02-00-04 2010985-01 2010985-02 6445033-01-00-01*Part of Upper Ram Subassembly. Item 6 not shown.TC1001 50 © <strong>2002</strong> Cooper Cameron, Cameron Division

ISR Shearing Blind RamInterlocking Shear Ram (ISR) is available for the U type BOP line. The ISR rams provide an improvedshearing capacity alternative to the standard SBR rams, and should only be used when the standardrams cannot handle the desired shearing load. Since the geometry of the ISR ram incorporates a “V”shape and is designed as wide as possible, it can shear multiple strings and drill pipe as large as 6-5/8”OD. Also, ISR rams do not have to fold over the lower fish. This means less force is required to shearand, by leaving the fish open, kill mud can be pumped down the severed drill string. The interlockingmechanism incorporated in the ISR means that these rams can be utilized in an oversized cavity withoutfear of a leak at low wellbore pressures.1012574923116SD 034603U and UM BOP ISR Shearing Blind RamBOP Bore Sizeand WorkingPressure (psi)13-5/8”3000, 5000 and10,000BOP Bore Sizeand WorkingPressure (psi)13-5/8”3000, 5000 and10,0002-7Upper RamSubassembly2Body3SidePackerDescription and Item Number4SidePacker5TopSeal6BladeSeal7BladeSeal2164775-01 2164773-01 2010985-01 2010985-02 6445033-01-00-01 2010986-01 2010986-029-14Lower RamSubassembly9Body10SidePacker11SidePacker12TopSeal13*BladeSeal14*BladeSeal2164776-01 2164774-01 20101985-01 2010985-02 6445033-01-00-01 2010986-01 2010986-02* Not ShownTC1001 51 © <strong>2002</strong> Cooper Cameron, Cameron Division

U, UL and UM BOP DSI and DVS Shear RamsDual string interlocking (DSI) shear rams and double V shear (DVS) rams are also available for the U,UL and UM BOPs. The interlocking feature of these rams provides the capability of shearing wirelineand braided cable with zero tension in the line, while still maintaining a seal. The blades are interlockedby using pockets in the lower ram and arms on the upper ram to prevent any gap betweenblade surfaces.DSI rams are similar to standard DS shear rams except for the interlock feature. DSI shear rams are capableof shearing tubing, small pipe, braided cable, slickline and solid sinker bar.DVS rams are similar in design to the standard shearing blind rams except that both blades are Vshaped and interlocked. The DVS rams are capable of shearing tubing, small pipe, braided cable andslickline.Top SealSide PackerUpper Shear RamUpperRam BodyLower Ram BodySide PackerLower Shear RamBlade SealUpper Shear RamDual String Interlocking (DSI) Shear RamsTop SealLower Ram BodyUpperRam BodySidePackerDouble V Shear (DVS) Shear RamsBlade PackerSD 034613TC1001 52 © <strong>2002</strong> Cooper Cameron, Cameron Division

U, UL and UM BOP Variable Bore Rams(VBR and VBR-II )The Cameron VBR-II is the next generation of the highly popular Cameron variable bore ram (VBR)packer. The patent pending VBR-II accomodates a range of pipe sizes and may be used in existingCameron variable bore rams. The VBR-II seals on a range of drill pipe sizes as well as hexagonal kellysand provides uniform sealing pressure with virtual elimination of extrusion paths.As indicated in the chart below, the VBR-II is the standard VBR in most common sizes. In sizes wherethe VBR-II is not specified in the chart, the popular Cameron VBR is the standard offering. VBR-IIpackers for other size BOPs and other pipe size ranges are available upon request.U, UL and UM BOP Variable Bore Ram Part NumbersBOP Size and WorkingPressure (psi)7-1/16” 3000, 5000,10,000 and 15,0007-1/16” 3000, 5000,10,000 and 15,00011” 3000, 5000 and10,000 VBR-IIPipe SizeRangeRamSubassemblyRamBodyPacker3-1/2” to 2-3/8” 615066-01 615065-01 614616-02 644214-02-00-014” to 2-7/8” 644901-01 614605-01 614616-02 644214-02-00-015” to 3-1/2” 645360-01 644836-01 644926-02 644217-01-00-0111” 15,000 5” to 2-7/8” 614456-01 644754-01 2010464-01 2010453-0213-5/8” 3000, 5000and 10,000 VBR-II7” to 4-1/2” 046675-01 046671-01-00-02 644924-03 644223-02-00-0113-5/8” 3000, 5000and 10,000 VBR-II13-5/8” 3000, 5000and 10,000 VBR-II5-1/2” to 3-1/2” 2163945-01 2011438-01 645089-02-00-01 644223-02-00-015” to 2-7/8” 645166-01 644744-01-00-04 645089-02-00-01 644223-02-00-0113-5/8” 15,000 7” to 5” 614104-01 614146-01 644924-02 644226-02-00-0113-5/8” 15,000 5” to 3-1/2” 614129-01 644745-01 644921-01 644226-02-00-0116-3/4” 5000 7” to 3-1/2” 046676-01 046672-01 644920-01-00-01 644229-01-00-0116-3/4” 10,000 5” to 2-7/8” 2163175-01 644746-01-00-01 645128-01-00-01 644229-02-00-0116-3/4” 10,000 5-1/2” to 3-1/2” 2164605-01 2164603-01 645128-01-00-01 644229-02-00-0116-3/4” 10,000 7” to 5” 046676-01 046672-01 644920-01-00-01 644229-01-00-0118-3/4” 10,000 VBR-II 7-5/8” to 3-1/2” 046677-01 046673-01 644927-02 644232-03-00-0121-1/4” 5000 and10,0005-7/8” to 2-7/8” 2164444-01 2164408-01 2164423-01 2164440-01TopSealTC1001 53 © <strong>2002</strong> Cooper Cameron, Cameron Division

U, UL and UM BOPFLEXPACKER and FLEXPACKER-NR The Cameron Flexpacker ram is the latest development in multiple-bore sealing. Each Flexpacker ramis designed to close and seal around several diameters of tubing and pipe. The CameronFlexpacker-NR is a narrow range variable bore ram packer designed for use with tapered drill strings.These packers can be used in existing Cameron BOPs.FLEXPACKER Sizes and Part NumbersBore Size and WorkingPressure (psi)11”3000, 5000 and 10,00013-5/8”3000, 5000 and 10,00018-3/4”10,00020-3/4”300021-1/4”2000Pipe SizeRangePackerPart NumberTop SealPart Number2-3/8” to 3-1/2” 2011740-01 644217-01-00-012-3/8” to 3-1/2” 2011716-01 644223-01-00-012-7/8” to 5” 645346-01 644232-045” to 7” 645353-01 2163261-015” to 7” 645353-01 2163621-01FLEXPACKER-NR Sizes and Part NumbersBOP Size and Working Pressure (psi) Pipe Size Range Part Number11” 3000, 5000 and 10,000 2-3/8” x 3-1/2” 2011740-0111” 3000, 5000 and 10,000 3-1/2” x 5” 2163445-0113-5/8” 3000, 5000 and 10,000 2-3/8” x 3-1/2” 2011716-0113-5/8” 3000, 5000 and 10,000 3-1/2” x 5” 2011673-0113-5/8” 3000, 5000 and 10,000 5” x 6-5/8” 2011688-0118-3/4” 10,000 5” x 6-5/8” 2011907-0118-3/4” 10,000 3-1/2” x 5” 2011701-01TC1001 54 © <strong>2002</strong> Cooper Cameron, Cameron Division