Mimaki Guide 2011.pdf - HOME

Mimaki Guide 2011.pdf - HOME

Mimaki Guide 2011.pdf - HOME

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

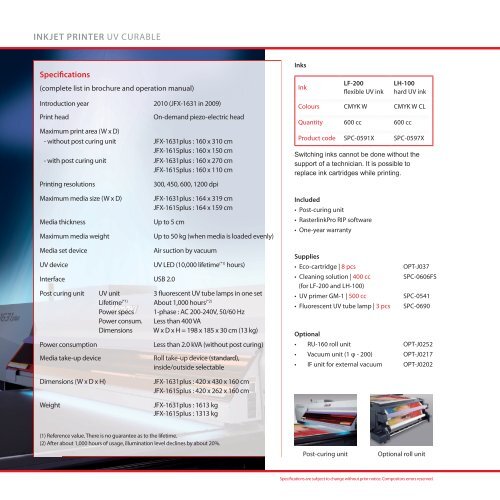

INKJET PRINTER UV CURABLEINKJET PRINTER UV CURABLESpecifications(complete list in brochure and operation manual)InksInkLF-200flexible UV inkLH-100hard UV inkUJV-160Innovative Hybrid UV LED PrinterPrinting on both roll and rigid mediaIntroduction year 2010 (JFX-1631 in 2009)Print headOn-demand piezo-electric headMaximum print area (W x D)- without post curing unit JFX-1631plus : 160 x 310 cmJFX-1615plus : 160 x 150 cm- with post curing unit JFX-1631plus : 160 x 270 cmJFX-1615plus : 160 x 110 cmPrinting resolutionsMaximum media size (W x D)Media thicknessMaximum media weightMedia set deviceUV device300, 450, 600, 1200 dpiJFX-1631plus : 164 x 319 cmJFX-1615plus : 164 x 159 cmUp to 5 cmInterface USB 2.0Up to 50 kg (when media is loaded evenly)Air suction by vacuumUV LED (10,000 lifetime (*1) hours)Post curing unit UV unit 3 fluorescent UV tube lamps in one setLifetime (*1) About 1,000 hours (*2)Power specs 1-phase : AC 200-240V, 50/60 HzPower consum. Less than 400 VADimensions W x D x H = 198 x 185 x 30 cm (13 kg)Power consumptionMedia take-up deviceDimensions (W x D x H)WeightLess than 2.0 kVA (without post curing)Roll take-up device (standard),inside/outside selectableJFX-1631plus : 420 x 430 x 160 cmJFX-1615plus : 420 x 262 x 160 cmJFX-1631plus : 1613 kgJFX-1615plus : 1313 kgColours CMYK W CMYK W CLQuantity 600 cc 600 ccProduct code SPC-0591X SPC-0597XSwitching inks cannot be done without thesupport of a technician. It is possible toreplace ink cartridges while printing.Included• Post-curing unit• RasterlinkPro RIP software• One-year warrantySupplies• Eco-cartridge | 8 pcs• Cleaning solution | 400 cc(for LF-200 and LH-100)• UV primer GM-1 | 500 cc• Fluorescent UV tube lamp | 3 pcsOptional• RU-160 roll unit• Vacuum unit (1 φ - 200)• IF unit for external vacuumOPT-J037SPC-0606FSSPC-0541SPC-0690OPT-J0252OPT-J0217OPT-J0202Product conceptWide format UV LED roll-to-roll printer that can alsoprint on rigid media, offering ultimate flexibility. Hardand flexible (stretchable up to 200%) inks are available.Effective Print & Cut workflow is available for both rolland rigid media.Incorporated technologies• UV LED printing technology• On-demand piezo-electric head• White Ink Overlay Function, printing white andfull colour simultaneously• Variable dot printing (3 dot sizes: S, M, L)• Stepless head height adjustment from 1.5 to 12.5 mm• RasterlinkPro RIP software• Two tables to handle rigid mediaPrint speeds1200 x 1200 dpi8 pass, uni-dir600 x 900 dpi6 pass, uni-dir5 m 2 /h 7 m 2 /hKey benefits / selling arguments• UV LED benefits: (please refer to theme page: UV LED Printing Technology)- Problem-free printing on heat sensitive media- Quick start up, no warm up time- No ozone and almost no VOCs emission• Printing roll-to-roll as well as on rigid media up to 12 kg weight• Hard and flexible inks (stretchable up to 200% depending on the media)• White ink and clear varnish available• 3M’s MCS warranty programme* for graphics printed with flexible inks• EDP award winner for The Best Wide Format Printer up to 1.6 m of 2009• Effective print and cut combo with CF2 series or CG-FXII series* Only when using 3M’s specific media and recommended methodTarget groupsSign makers, print shops, and screen printers.Substrates• Vinyl• Banner• Canvas• Backlit• Carton• PaperLevels of adhesion differ between materials, please test in advance.(Please refer to theme page: How to Improve UV Ink Adhesion)Applications (also see the theme page: Applications Library)• Vehicle wrapping• Exhibition signs• Rigid packagingRelevant pages to read:INKS & SOFTWARETHEME PAGES• UV LED printing technology• How to improve UV ink adhesion• POS displays• Labels and stickers• Photo / art reproduction• Channelboard / tunnelboard• Aluminium composite panels• Acrylics and foam board• Signboards• Posters• Applications library• <strong>Mimaki</strong> in practice(1) Reference value. There is no guarantee as to the lifetime.(2) After about 1,000 hours of usage, illumination level declines by about 20%.Post-curing unitOptional roll unit* Print speeds depend upon factors, such as printmode, image, media and profi les. Depending onprint mode, uncured UV ink remains.Related productsUV FLATBED PRINTERSUJF-3042 UJF-706JFX plusCUTTING MACHINESCG-FXII Series (roll)CF2 Series (flatbed)Specifications are subject to change without prior notice. Compositors errors reserved.