wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

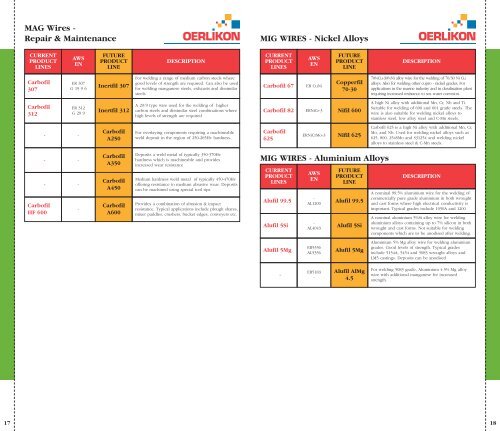

MAG Wires -Repair & MaintenanceMIG WIRES - Nickel AlloysCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONCarbofil307ER 307G 19 9 6 Inertfil 307For welding a range of medium carbon steels wheregood levels of strength are required. Can also be usedfor welding manganese steels, exhausts and dissimilarsteels.Carbofil 67ER CuNiCopperfil70-3070%Cu-30%Ni alloy wire for the welding of 70/30 Ni Cualloys. Also for welding other cupro - nickel grades. Forapplications in the marine industry and in desalination plantrequiring increased resistance to sea water <strong>co</strong>rrosion.Carbofil312ER 312G 29 9 Inertfil 312A 29/9 type wire used for the welding of highercarbon steels and dissimilar steel <strong>co</strong>mbinations wherehigh levels of strength are requiredCarbofil 82 ERNiCr-3 Nifil 600A high Ni alloy with additional Mn, Cr, Nb and Ti.Suitable for welding of 600 and 601 grade steels. Thewire is also suitable for welding nickel alloys tostainless steel, low alloy steel and C-Mn steels.- -CarbofilA250For overlaying <strong>co</strong>mponents requiring a machineableweld deposit in the region of 250-265Hv hardness.Carbofil625ERNiCrMo-3 Nifil 625Carbofil 625 is a high Ni alloy with additional Mn, Cr,Mo, and Nb. Used for welding nickel alloys such as625, 800, 254SMo and S31254 and welding nickelalloys to stainless steel & C-Mn steels.CarbofilHF 600- -- --CarbofilA350CarbofilA450CarbofilA600Deposits a weld metal of typically 350-370Hvhardness which is machineable and providesincreased wear resistanceMedium hardness weld metal of typically 450-470Hvoffering resistance to medium abrasive wear. Depositscan be machined using special tool tips.Provides a <strong>co</strong>mbination of abrasion & impactresistance. Typical applications include plough shares,mixer paddles, crushers, bucket edges, <strong>co</strong>nveyers etc.MIG WIRES - Aluminium AlloysCURRENTPRODUCTLINESAlufil 99.5Alufil 5SiAWSENFUTUREPRODUCTLINE-AL1200 Alufil 99.5-AL4043Alufil 5SiDESCRIPTIONA nominal 99.5% aluminium wire for the welding of<strong>co</strong>mmercially pure grade aluminium in both wroughtand cast forms where high electrical <strong>co</strong>nductivity isimportant. Typical grades include 1050A and 1200A nominal aluminium 5%Si alloy wire for weldingaluminium alloys <strong>co</strong>ntaining up to 7% sili<strong>co</strong>n in bothwrought and cast forms. Not suitable for welding<strong>co</strong>mponents which are to be anodised after welding.Alufil 5MgER5356AL5356Alufil 5MgAluminium 5% Mg alloy wire for welding aluminiumgrades. Good levels of strength. Typical gradesinclude 5154A, 5454 and 5083 wrought alloys andLM5 castings. Deposits can be anodised-ER5183-Alufil AlMg4.5For welding 5083 grade, Aluminium 4.5% Mg alloywire with additional manganese for increasedstrength.1718