wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

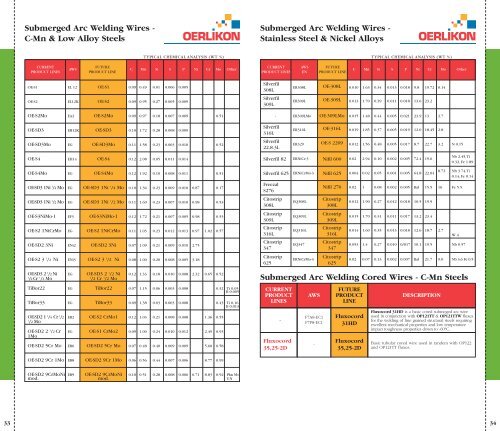

Submerged Arc <strong>Welding</strong> Wires -C-Mn & Low Alloy SteelsSubmerged Arc <strong>Welding</strong> Wires -Stainless Steel & Nickel AlloysTYPICAL CHEMICAL ANALYSIS (WT %) TYPICAL CHEMICAL ANALYSIS (WT %)CURRENTPRODUCT LINESAWSFUTUREPRODUCT LINEC Mn Si S P Ni Cr Mo OtherCURRENT AWS FUTUREPRODUCT LINES EN PRODUCT LINEC Mn Si S P Ni Cr Mo OtherOE-S1 EL 12 OE-S1 0.09 0.49 0.01 0.006 0.005OE-S2 EL12K OE-S2 0.09 0.95 0.27 0.005 0.009Silverfil308LSilverfil309LER308L OE-308L 0.010 1.63 0.34 0.013 0.018 9.8 19.72 0.14ER309L OE-309L 0.013 1.70 0.39 0.011 0.018 13.6 23.2OE-S2Mo EA2 OE-S2Mo 0.09 0.97 0.18 0.007 0.009 0.51- ER309LMo OE-309LMo 0.015 1.48 0.44 0.005 0.021 23.9 13 2.7OE-SD3 EH12K OE-SD3 0.10 1.72 0.28 0.008 0.009OE-SD3Mo EG OE-SD3Mo 0.11 1.58 0.23 0.003 0.010 0.52Silverfil316LSilverfil22.8.3LER316L OE-316L 0.019 1.85 0.37 0.005 0.019 12.0 18.45 2.8ER329 OE-S 2209 0.012 1.56 0.48 0.005 0.017 8.7 22.7 3.2 N 0.15OE-S4 EH14 OE-S4 0.12 2.08 0.05 0.011 0.014Silverfil 82 ERNiCr-3 Nifil 600 0.02 2.94 0.10 0.002 0.005 72.4 19.6Nb 2.45,Ti0.32, Fe 1.89OE-S4Mo EG OE-S4Mo 0.12 1.92 0.10 0.008 0.011 0.51OE-SD3 1Ni 1 /4 Mo EG OE-SD3 1Ni 1 /4 Mo 0.10 1.36 0.23 0.009 0.010 0.87 0.17OE-SD3 1Ni 1 /2 Mo EG OE-SD3 1Ni 1 /2 Mo 0.11 1.60 0.23 0.007 0.010 0.98 0.53OE-S3NiMo-1 EF3 OE-S3NiMo-1 0.12 1.72 0.21 0.007 0.005 0.98 0.53OE-S2 1NiCrMo EG OE-S2 1NiCrMo 0.11 1.03 0.23 0.012 0.013 0.97 1.02 0.57OE-SD2 3Ni ENi2 OE-SD2 3Ni 0.07 1.09 0.21 0.009 0.010 2.75OE-S2 3 1 /2 Ni ENi3 OE-S2 3 1 /2 Ni 0.08 1.00 0.20 0.008 0.005 3.18OE-SD3 2 1 /2 Ni EG OE-SD3 2 1 /2 Ni 0.12 1.33 0.18 0.010 0.008 2.32 0.65 0.521/2 Cr 1 /2 Mo 1/2 Cr 1 /2 MoTiBor22 EG TiBor22 0.07 1.15 0.06 0.003 0.008 0.32 Ti 0.05B 0.005TiBor33 EG TiBor33 0.09 1.38 0.03 0.003 0.008 0.43 Ti 0.16B 0.013OE-SD2 1 1 /4 Cr 1 /2 EB2 OE-S2 CrMo1 0.12 1.03 0.21 0.008 0.008 1.36 0.551/2 MoOE-SD2 2 1 /2 Cr EG OE-S1 CrMo2 0.09 1.00 0.24 0.010 0.012 2.45 0.931MoOE-SD2 5Cr Mo EB6 OE-SD2 5Cr Mo 0.07 0.48 0.40 0.009 0.009 5.60 0.58Silverfil 625 ERNiCrMo-3 Nifil 625 0.004 0.02 0.05 0.001 0.005 64.8 22.04FreezalS276CitostripCitostripEQ308L308L308LCitostripCitostripEQ309L309L309LCitostripCitostripEQ316L316L316LCitostripCitostripEQ347347 347CitostripCitostripERNiCrMo-3625 6258.72 Nb 3.74,Ti0.14, Fe 0.14Nifil 276 0.02 1 0.08 0.002 0.005 Bal 15.5 16 Fe 5.50.012 1.90 0.27 0.012 0.018 10.5 19.90.015 1.70 0.31 0.011 0.017 13.2 23.40.014 1.60 0.35 0.013 0.018 12.6 18.7 2.70.053 1.4 0.27 0.010 0/017 10.1 19.5 Nb 0.570.02 0.07 0.13 0.002 0.007 Bal 21.7 9.0 Nb 3.6 Fe 0.5Submerged Arc <strong>Welding</strong> Cored Wires - C-Mn SteelsCURRENTPRODUCTLINES-Fluxo<strong>co</strong>rd35,25-2DAWSF7A8-EC1F7P8-EC1-FUTUREPRODUCTLINEFluxo<strong>co</strong>rd31HDFluxo<strong>co</strong>rd35,25-2DDESCRIPTIONW 4Fluxo<strong>co</strong>rd 31HD is a basic <strong>co</strong>red submeged arc wireused in <strong>co</strong>njunction with OP121TT & OP121TTW fluxesfor the welding of fine grained structural steels requiringexcellent mechanical properties and low temperatureimpact toughness properties down to -60°C.Basic tubular <strong>co</strong>red wire used in tandem with OP122and OP121TT fluxes.OE-SD2 9Cr 1Mo EB8 OE-SD2 9Cr 1Mo 0.06 0.56 0.44 0.007 0.006 8.77 0.99OE-SD2 9CrMoNi EB9 OE-SD2 9CrMoNi 0.10 0.51 0.28 0.008 0.006 0.71 8.83 0.92 Plus Nbmod. mod. V,N3334