wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

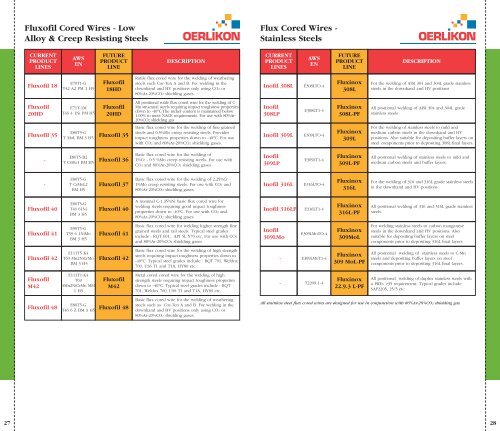

Fluxofil Cored Wires - LowAlloy & Creep Resisting SteelsFlux Cored Wires -Stainless SteelsCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONFluxofil 18E70T1-GT42 A2 PM 1 H5Fluxofil18HDRutile flux <strong>co</strong>red wire for the welding of weatheringsteels such Cor-Ten A and B. For welding in thedownhand and HV positions only using CO2 or80%Ar-20%CO2 shielding gases.Inofil 308LE308LTO-4Fluxinox308LFor the welding of AISI 304 and 304L grade stainlesssteels in the downhand and HV positionsFluxofil20HDFluxofil 35E71T-1MT46 4 1Ni PM H5Fluxofil20HDE80T5-GT MoL BM 3 H5 Fluxofil 35All positional rutile flux <strong>co</strong>red wire for the welding of C-Mn structural steels requiring impact toughness propertiesdown to -40°C.The nickel <strong>co</strong>ntent is maintained below1.00% to meet NACE requirements. For use with 80%Ar-20%CO2 shielding gasBasic flux <strong>co</strong>red wire for the welding of fine grainedsteels and 0.5%Mo creep resisting steels. Providesimpact toughness properties down to -40°C. For usewith CO2 and 80%Ar-20%CO2 shielding gases.Inofil308LPInofil 309LE308LT1-4E309LTO-4Fluxinox308L-PFFluxinox309LAll positional welding of AISI 304 and 304L gradestainless steelsFor the welding of stainless steels to mild andmedium carbon steels in the downhand and HVpositions. Also suitable for depositing buffer layers onsteel <strong>co</strong>mponents prior to depositing 308L final layers.-E80T5-B2T CrMo1 BM H5 Fluxofil 36Basic flux <strong>co</strong>red wire for the welding of1%Cr - 0.5 %Mo creep resisting steels. For use withCO2 and 80%Ar-20%CO2 shielding gasesInofil309LPE309LT1-4Fluxinox309L-PFAll positional welding of stainless steels to mild andmedium carbon steels and buffer layers.-E80T5-GT CrMoL2BM H5Fluxofil 37Basic flux <strong>co</strong>red wire for the welding of 2.25%Cr -1%Mo creep resisting steels. For use with CO2 and80%Ar-20%CO2 shielding gases.Inofil 316LE316LTO-4Fluxinox316LFor the welding of 316 and 316L grade stainless steelsin the downhand and HV positionsFluxofil 40E80T5-GT46 61NiBM 3 H5Fluxofil 40A nominal C-1.35%Ni basic flux <strong>co</strong>red wire forwelding steels requiring good impact toughnessproperties down to -40°C. For use with CO2 and80%Ar-20%CO2 shielding gasesInofil 316LPE316LT1-4Fluxinox316L-PFAll positional welding of 316 and 316L grade stainlesssteels.Fluxofil 41E90T5-GT55 6 1NiMoBM 3 H5Fluxofil 41Basic flux <strong>co</strong>red wire for welding higher strength finegrained steels and rail steels. Typical steel gradesinclude : RQT 601, API 5L X70 etc. For use with CO2and 80%Ar-20%CO2 shielding gasesInofil309LMoE309LMoTO-4Fluxinox309MoLFor welding stainless steels to carbon manganesesteels in the downhand and HV positions. Alsosuitable for depositing buffer layers on steel<strong>co</strong>mponents prior to depositing 316L final layersFluxofil 42E111T5 K4T69 Mn2NiCrMoBM 3 H5Fluxofil 42Basic flux <strong>co</strong>red wire for the welding of high strengthsteels requiring impact toughness properties down to-40°C. Typical steel grades include : RQT 701, Weldox700, USS T1 and T1A, HY80 etc.- E309LMoT1-4Fluxinox309 MoL-PFAll positional welding of stainless steels to C-Mnsteels and depositing buffer layers on steel<strong>co</strong>mponents prior to depositing 316L final layers.FluxofilM42Fluxofil 48E111T1-K4T694Mn2NiCrMo MM1 H5FluxofilM42Metal <strong>co</strong>red <strong>co</strong>red wire for the welding of highstrength steels requiring impact toughness propertiesdown to -40°C. Typical steel grades include : RQT701, Weldox 700, USS T1 and T1A, HY80 etc.Basic flux <strong>co</strong>red wire for the welding of weatheringE80T5-GT46 6 Z BM 3 H5 Fluxofil 48 steels such as Cor-Ten A and B. For welding in thedownhand and HV positions only using CO2 or80%Ar-20%CO2 shielding gases.- T2209 1-4Fluxinox22.9.3 L-PFAll positional welding of duplex stainless steels witha PREN >35 requirement. Typical grades includeSAF2205, 25/5 etcAll stainless steel flux <strong>co</strong>red wires are designed for use in <strong>co</strong>njunction with 80%Ar-20%CO2 shielding gas.2728