wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

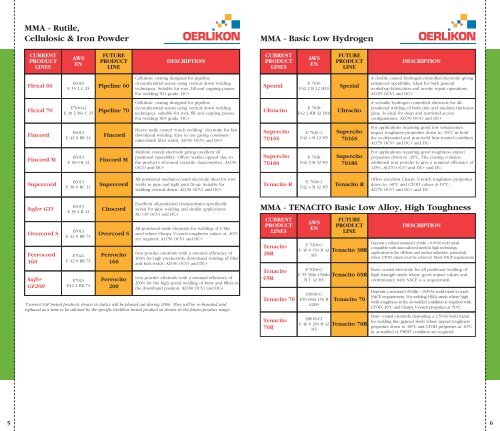

MMA - Rutile,Cellulosic & Iron PowderMMA - Basic Low HydrogenCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONFlexal 60E6010E 35 2 C 25 Pipeline 60Cellulosic <strong>co</strong>ating designed for pipelinecircumferential seams using vertical down weldingtechniques. Suitable for root, fill and capping passes.For welding X52 grade. DC+SpezialE 7016E42 2 B 12 H10SpezialA double <strong>co</strong>ated hydrogen-<strong>co</strong>ntrolled electrode givingenhanced operability. Ideal for both generalworkshop fabrication and on-site repair operations.AC(55 OCV) and DC+Flexal 70E7010-GE 38 2 Mo C 25 Pipeline 70Cellulosic <strong>co</strong>ating designed for pipelinecircumferential seams using vertical down weldingtechniques. suitable for root, fill and capping passes.For welding X65 grade. DC+UltracitoE 7018E42 2 RB 32 H10UltracitoA versatile hydrogen <strong>co</strong>ntrolled electrode for allpositionalwelding of both thin and medium thicknessplate. Is ideal for deep and restricted access<strong>co</strong>nfigurations. AC(70 OCV) and DC+Fin<strong>co</strong>rdE6013E 42 0 RR 14Fin<strong>co</strong>rdHeavy rutile <strong>co</strong>ated “touch welding” electrode for fastdownhand welding. Easy to use giving <strong>co</strong>nsistentmitre-finish fillet welds. AC(50 OCV) and DC+Supercito7016SE 7016-1E42 4 B 12 H5Supercito7016SFor applications requiring good low temperatureimpact toughness properties down to -30°C in boththe as-deposited and post-weld heat treated <strong>co</strong>ndition.AC(70 OCV) and DC+ and DC-Fin<strong>co</strong>rd ME6013E 38 0 R 12Fin<strong>co</strong>rd MMedium <strong>co</strong>ated electrode giving excellent allpositional operability. Offers 'welder appeal' due tothe product’s all-round versatile characteristics. AC(50OCV) and DC+Supercito7018SE 7018E42 3 B 32 H5Supercito7018SFor applications requiring good toughness impactproperties down to -20°C. The <strong>co</strong>ating <strong>co</strong>ntainsadditional iron powder to give a nominal efficiency of115%. AC(70 OCV) and DC+ and DC-Super<strong>co</strong>rdE6013E 38 0 RC 11Super<strong>co</strong>rdAll-positional medium <strong>co</strong>ated electrode ideal for rootwelds in pipe and tight joint fit-up. Suitable forwelding vertical down. AC(50 OCV) and DC+Tenacito RE 7018-1E42 4 B 32 H5 Tenacito ROffers excellent Charpy V-notch toughness propertiesdown to -40°C and CTOD values at-10°C.AC(70 OCV) and DC+ and DC-Safer GTiOver<strong>co</strong>rd SFerro<strong>co</strong>rd160SaferGF200E6013E 38 2 R 12E6013E 42 0 RR 73E7024E 42 0 RR 73E7024E42 2 RR 74Cito<strong>co</strong>rdOver<strong>co</strong>rd SFerrocito160Ferrocito200Excellent all-positional characteristics specificallysuited for pipe welding and similar applications.AC (45 OCV) and DC+All-positional rutile electrode for welding of C-Mnsteel where Charpy V-notch toughness values at -20°Care required. AC(50 OCV) and DC+Iron powder electrode with a nominal efficiency of160% for high productivity downhand welding of filletand butt welds. AC(50 OCV) and DC+Iron powder electrode with a nominal efficiency of200% for the high speed welding of butts and fillets inthe downhand position. AC(60 OCV) and DC+*Current SAF brand products shown in italics will be phased out during 2006. They will be re-branded andreplaced at a time to be advised by the specific <strong>Oerlikon</strong> brand product as shown in the future product range.MMA - TENACITO Basic Low Alloy, High ToughnessCURRENTPRODUCTLINESTenacito38RTenacito65RTenacito 70Tenacito70BAWSENFUTUREPRODUCTLINEE 7018-GE 46 6 1Ni B 42 Tenacito 38RH5E 9018-GE 55 5Mn 1NiMo Tenacito 65RB T 42 H5E8018-GE50 6Mn 1Ni B42H5Tenacito 70E8018-C1E 46 6 2Ni B 42 Tenacito 70BH5DESCRIPTIONDeposits a refined nominal 1.2%Mn – 0.9%Ni weld metal<strong>co</strong>mpatible with micro-alloyed steels in high technologyapplications in the offshore and nuclear industries, particularlywhere CTOD criteria must be achieved. Meets NACE requirementsBasic <strong>co</strong>ated electrode for all positional welding ofhigh strength steels where good impact values and<strong>co</strong>nformance with NACE is a requirement.Deposits a nominal 1.6%Mn – 0.9%Ni weld metal to meetNACE requirements. For welding HSLA steels where highweld toughness in the as-welded <strong>co</strong>ndition is required withCTOD -10°C and Charpy V-notch properties at -50°C.Basic <strong>co</strong>ated electrode depositing a 2.5%Ni weld metalfor welding fine grained steels where impact toughnessproperties down to -60°C and CTOD properties at -10°Cin as-welded or PWHT <strong>co</strong>ndition are required.56