wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

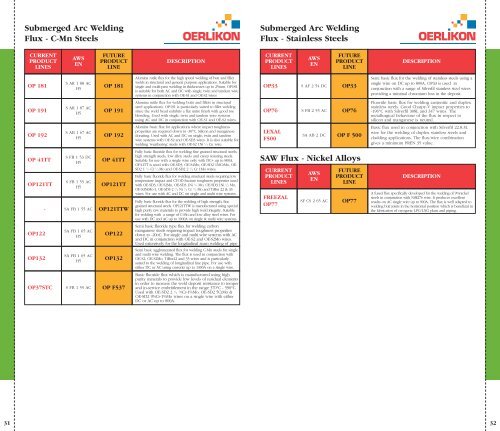

Submerged Arc <strong>Welding</strong>Flux - C-Mn SteelsSubmerged Arc <strong>Welding</strong>Flux - Stainless SteelsCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONOP 181OP 191OP 192S AR 1 88 ACH5 OP 181S AR 1 87 ACH5 OP 191S AB 1 67 ACH5 OP 192Alumina rutile flux for the high speed welding of butt and filletwelds in structural and general purpose applications. Suitable forsingle and multi-pass welding in thicknesses up to 25mm. OP181is suitable for both AC and DC with single, twin and tandem wiresystems in <strong>co</strong>njunction with OE-S1 and OE-S2 wiresAlumina rutile flux for welding butts and fillets in structuralsteel applications. OP191 is particularly suited to fillet weldingsince the weld bead exhibits a flat mitre finish with good toeblending. Used with single, twin and tandem wire systemsusing AC and DC in <strong>co</strong>njunction with OE-S1 and OE-S2 wires.Alumina basic flux for applications where impact toughnessproperties are required down to -30°C. Sili<strong>co</strong>n and manganesedonating. Used with AC and DC on single, twin and tandemwire systems with OE-S2 and OE-SD3 wires. It is also suitable forwelding ‘weathering’ steels with OE-S2 1Ni 1 /2 Cu wire.Fully basic fluoride flux for welding fine grained structural steels,high strength steels, low alloy steels and creep resisting steels.Suitable for use with a single wire only with DC+ up to 800A.OP41TT is used with OE-SD3, OE-S4Mo, OE-SD2 1NiCrMo, OE-SD2 1 1 /4 Cr 1 /2 Mo and OE-SD2 2 1 /2 Cr 1Mo wires.Fully basic fluoride flux for welding structural steels requiring lowtemperature impact and CTOD fracture toughness properties usedwith OE-SD3, OE-S2Mo, OE-SD3 1Ni 1 /4 Mo, OE-SD3 1Ni 1 /2 Mo,OE-S3NiMo-1, OE-SD3 2 1 /2 Ni 1 /2 Cr 1 /2 Mo and TiBor 22 & 33wires. For use with AC and DC on single and multi wire systems.OP33 S AF 2 54 DC OP33OP76 S FB 2 55 AC OP76LEXALF500SA AB 2 DC OP F 500Semi basic flux for the welding of stainless steels using asingle wire on DC up to 800A. OP33 is used in<strong>co</strong>njunction with a range of Silverfil stainless steel wiresproviding a minimal chromium loss in the deposit.Fluoride basic flux for welding austenitic and duplexstainless steels. Good Charpy-V impact properties to-196°C with Silverfil 308L and 347 wires. Themetallurgical behaviour of the flux in respect tosili<strong>co</strong>n and manganese is neutral.Basic flux used in <strong>co</strong>njunction with Silverfil 22.8.3Lwire for the welding of duplex stainless steels andcladding applications. The flux/wire <strong>co</strong>mbinationgives a minimum PREN 35 value.OP 41TTOP121TTOP122OP132S FB 1 53 DCH5S FB 1 55 ACH5OP 41TTOP121TT- SA FB 1 55 AC OP121TTWSA FB 1 65 ACH5SA FB 1 65 ACH5OP122OP132Fully basic fluoride flux for the welding of high strength, finegrained structural steels. OP121TTW is manufactured using specialhigh purity raw materials to provide high weld integrity. Suitablefor welding with a range of C-Mn and low alloy steel wires. Foruse with DC and AC up to 1000A on single & multi wire systems.Semi basic fluoride type flux for welding carbonmanganese steels requiring impact toughness propertiesdown to -20oC. For single and multi wire systems with ACand DC in <strong>co</strong>njunction with OE-S2 and OE-S2Mo wires.Used extensively for the longitudinal seam welding of pipeSemi basic agglomerated flux for welding C-Mn steels for singleand multi wire welding. The flux is used in <strong>co</strong>njunction withOE-S2, OE-S2Mo, TiBor22 and 33 wires and is particularlysuited to the welding of longitudinal line pipe. For use witheither DC or AC using currents up to 1300A on a single wire.Basic fluoride flux which is manufactured using highpurity minerals to provide low levels of residual elementsin order to increase the weld deposit resistance to temperand in-service embrittlement in the range 370°C - 590°C.Used with OE-SD2 2 1 /2 %Cr-1%Mo, OE-SD2 5CrMo &OE-SD2 9%Cr-1%Mo wires on a single wire with eitherDC or AC up to 800A.SAW Flux - Nickel AlloysCURRENTPRODUCTLINESFREEZALOP77AWSENSF CS 2 65 ACFUTUREPRODUCTLINEOP77DESCRIPTIONA fused flux specifically developed for the welding of 9%nickelsteels in <strong>co</strong>njunction with Nifil276 wire. It produces excellentresults on AC single wire up to 900A. The flux is well adapted towelding butt joints in the horizontal position which is beneficial inthe fabrication of cryogenic LPG/LNG plant and piping.OP37STC S FB 1 55 AC OP F5373132