wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

wecs-ltd.co.uk Oerlikon Welding Consumable Product Guide 06.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

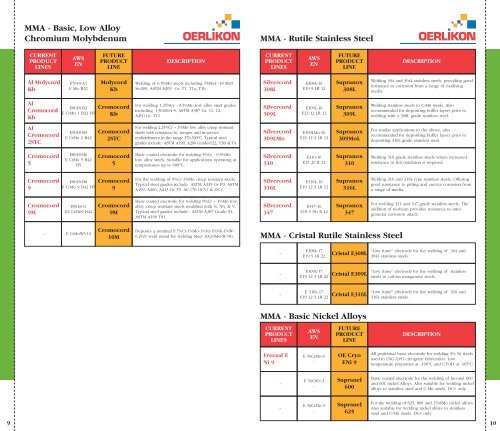

MMA - Basic, Low AlloyChromium MolybdenumMMA - Rutile Stainless SteelCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONAl Moly<strong>co</strong>rdKbE7018-A1E Mo B32Moly<strong>co</strong>rdKb<strong>Welding</strong> of 0.5%Mo steels including 15Mo3 -19 Mn5Ste285, ASTM A209 Gr. T1, T1a, T1bSilver<strong>co</strong>rd308LE308L-16E19 9 LR 12Supranox308L<strong>Welding</strong> 304 and 304L stainless steels, providing goodresistance to <strong>co</strong>rrosion from a range of oxidisingmedia.AlCromo<strong>co</strong>rdKbE8018-B2 Cromo<strong>co</strong>rdE CrMo 1 B32 H5 KbFor welding 1.25%Cr - 0.5%Mo low alloy steel gradesincluding 13CrMo4-5, ASTM A387 Gr. 11, 12,A200 Gr. T11Silver<strong>co</strong>rd309LE309L-16E23 12 LR 12Supranox309L<strong>Welding</strong> stainless steels to C-Mn steels. Alsore<strong>co</strong>mmended for depositing buffer layers prior towelding with a 308L grade stainless steel.AlCromo<strong>co</strong>rd2STCE9018-B3E CrMo 2 B42Cromo<strong>co</strong>rd2STCFor welding 2.25%Cr – 1%Mo low alloy creep resistantsteels with resistance to temper and in-serviceembrittlement in the range 370-590°C. Typical steelgrades include ASTM A199, A200 GradesT22, T3B & T4.Silver<strong>co</strong>rd309LMoE309LMo-16E23 12 2 LR 12Supranox309MoLFor similar applications to the above, alsore<strong>co</strong>mmended for depositing buffer layers prior todepositing 316L grade stainless steel.Cromo<strong>co</strong>rd5E8018-B6E CrMo 5 B42H5Cromo<strong>co</strong>rd5Basic <strong>co</strong>ated electrode for welding 5%Cr - 0.5%Molow alloy steels. Suitable for applications operating attemperatures up to 600°C.Silver<strong>co</strong>rd310E310-16E25 20 R 12Supranox310<strong>Welding</strong> 310 grade stainless steels where increasedresistance to hot oxidation is required.Cromo<strong>co</strong>rd9E8018-B8 Cromo<strong>co</strong>rdE CrMo 9 B42 H5 9For the welding of 9%Cr-1%Mo creep resistant steels.Typical steel grades include ASTM A335 Gr P9, ASTMA199, A200, A213 Gr T9. AC (70 OCV) & DC+.Silver<strong>co</strong>rd316LE316L-16E19 12 3 LR 12Supranox316L<strong>Welding</strong> 316 and 316L type stainless steels. Offeringgood resistance to pitting and crevice <strong>co</strong>rrosion froma range of media.Cromo<strong>co</strong>rd9ME9018-GEZ CrMo9 B42Cromo<strong>co</strong>rd9MBasic <strong>co</strong>ated electrode for welding 9%Cr – 1%Mo lowalloy creep resistant steels modified with N, Nb, & V.Typical steel grades include : ASTM A387 Grade 91,ASTM A199 T91.Silver<strong>co</strong>rd347E347-16E19 9 Nb R 12Supranox347For welding 321 and 347 grade stainless steels. Theaddition of niobium provides resistance to intergranular<strong>co</strong>rrosion attack.- E CrMoWV10Cromo<strong>co</strong>rd10MDeposits a nominal 9.7%Cr-1%Mo-1%Ni-1%Nb-1%W-0.2%V weld metal for welding Steel 10Cr0Mo-W-NbMMA - Cristal Rutile Stainless Steel-E308L-17E19 9 LR 22Cristal E308L“Low fume” electrode for the welding of 304 and304L stainless steels.-E309L-17E19 12 3 LR 22“Low fume” electrode for the welding of stainlessCristal E309L steels to carbon manganese steels.-E 316L-17E19 12 3 LR 22“Low fume” electrode for the welding of 316 andCristal E316L 316L stainless steels.MMA - Basic Nickel AlloysCURRENTPRODUCTLINESAWSENFUTUREPRODUCTLINEDESCRIPTIONFreezal ENi 9E NiCrMo-6-OE CryoENi 9All positional basic electrode for welding 9% Ni steelsused in LNG/LPG cryogenic fabrication. Lowtemperature properties at -196°C and CTOD at -165°C-E NiCrFe-3-Supranel600Basic <strong>co</strong>ated electrode for the welding of In<strong>co</strong>nel 600and 601 nickel Alloys. Also suitable for welding nickelalloys to stainless steel and C-Mn steels. DC+ only-E NiCrMo-3-Supranel625For the welding of 625, 800 and 254SMo nickel alloys.Also suitable for welding nickel alloys to stainlesssteel and C-Mn steels. DC+ only910