Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

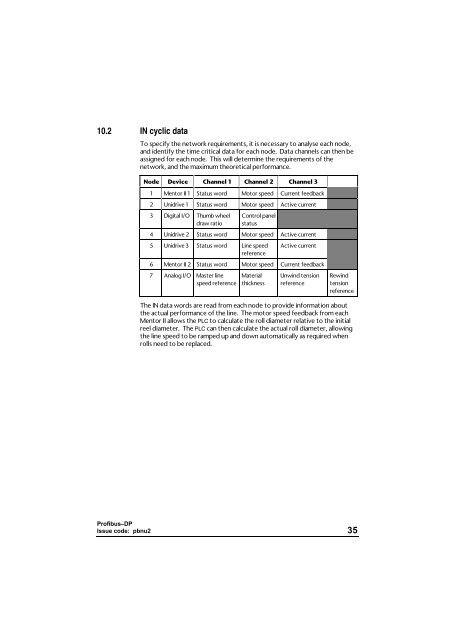

10.2 IN cyclic dataTo specify the network requirements, it is necessary to analyse each node,and identify the time critical data for each node. Data channels can then beassigned for each node. This will determine the requirements of thenetwork, and the maximum theoretical performance.Node Device Channel 1 Channel 2 Channel 31 Mentor II 1 Status word Motor speed Current feedback2 Unidrive 1 Status word Motor speed Active current3 Digital I/O Thumb wheeldraw ratioControl panelstatus4 Unidrive 2 Status word Motor speed Active current5 Unidrive 3 Status word Line speedreferenceActive current6 Mentor II 2 Status word Motor speed Current feedback7 Analog I/O Master linespeed referenceMaterialthicknessUnwind tensionreferenceRewindtensionreferenceThe IN data words are read from each node to provide information aboutthe actual performance of the line. The motor speed feedback from eachMentor II allows the PLC to calculate the roll diameter relative to the initialreel diameter. The PLC can then calculate the actual roll diameter, allowingthe line speed to be ramped up and down automatically as required whenrolls need to be replaced.<strong>Profibus</strong>–<strong>DP</strong>Issue code: pbnu2 35

![[Instruction] Contents](https://img.yumpu.com/51325878/1/184x260/instruction-contents.jpg?quality=85)