Part 2 - Miller Publishing Corporation

Part 2 - Miller Publishing Corporation

Part 2 - Miller Publishing Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

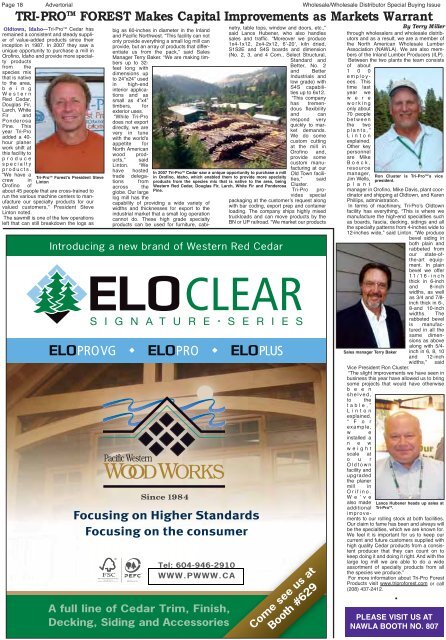

Page 18 Advertorial Wholesale/Wholesale Distributor Special Buying IssueTRI-PRO TM FOREST Makes Capital Improvements as Markets WarrantOldtown, Idaho—Tri-Pro TM Cedar hasremained a consistent and steady supplierof value-added products since theirinception in 1987. In 2007 they saw aunique opportunity to purchase a mill inOrofino, Idaho and provide more specialtyproductsfrom thespecies mixthat is nativeto the area,b e i n gWesternRed Cedar,Douglas Fir,Larch, WhiteFir andPonderosaPine. Thisyear Tri-Proadded a 40-hour planerwork shift atthis facility toproducespecialtyproducts.“We have aTri-Procrew inTM Forestʼs President SteveLintonOrofino ofabout 45 people that are cross-trained torun the various machine centers to manufactureour specialty products for ourvalued customers,” President SteveLinton noted.The sawmill is one of the few operationsleft that can still breakdown the logs asbig as 60-inches in diameter in the Inlandand Pacific Northwest. “This facility can notonly provide everything a small log mill canprovide, but an array of products that differentiateus from the pack,” said SalesManager Terry Baker. “We are making timbersup to 32-feet long withdimensions upto 24”x24” usedin high-endinterior applicationsand assmall as 4”x4”timbers, forexterior uses.“While Tri-Prodoes not exportdirectly, we arevery in tunewith the worldʼsappetite forNorth Americanwood products,”saidLinton. “Wehave hostedtrade delegationsfromacross theglobe. Our largelog mill has thecapability of providing a wide variety ofwidths and thicknesses for export to theindustrial market that a small log operationcannot do. These high grade specialtyproducts can be used for furniture, cabi-Introducing a new brand of Western Red CedarSince 1984Focusing on Higher StandardsdFocusing on the consumerTel: 604-946-2910WWW.PWWW.CAA full line of Cedar Trim, Finish,Decking, Siding and Accessoriessoriesnetry, table tops, window and doors, etc.,”said Lance Hubener, who also handlessales and traffic. “Moreover we produce1x4-1x12, 2x4-2x12, 6ʼ-20ʼ, kiln dried,S1S2E and S4S boards and dimension(No. 2, 3, and 4 Com., Select Structural,Standard andBetter, No. 2and BetterIndustrials andlow grade) withS4S capabilitiesup to 6x12.“This companyhas tremendousflexibilityand canrespond veryquickly to marketdemands.We do somecustom cuttingat the mill inOrofino and,In 2007 Tri-Pro TM Cedar saw a unique opportunity to purchase a millin Orofino, Idaho, which enabled them to provide more specialtyproducts from the species mix that is native to the area, beingWestern Red Cedar, Douglas Fir, Larch, White Fir and PonderosaPine.provide somecustom manufacturingat ourOld Town facilities,”saidCluster.Tri-Pro providesspecialpackaging at the customerʼs request alongwith bar coding, export prep and containerloading. The company ships highly mixedtruckloads and can move products by theBN or UP railroad. “We market our productsCome see us atBooth #629By Terry <strong>Miller</strong>through wholesalers and wholesale distributorsand as a result, we are a member ofthe North American Wholesale LumberAssociation (NAWLA). We are also membersof the Inland Lumber Producers (ILP).Between the two plants the team consistsof about1 0 0employees.Thistime lastyear wew e r eworkingonly about70 peoplebetweenthe twoplants,”Lintonexplained.Other keypersonnelare MikeBoeck,resourcemanager,Ron Cluster is Tri-ProJim Wells,TMʼs vicepresident.p l a n tmanager in Orofino, Mike Davis, plant coordinatorand shipping at Oldtown, and KarenPhillips, administration.In terms of machinery, Tri-Proʼs Oldtownfacility has everything. “This is where wemanufacture the high-end specialties suchas boards, fascia, decking, sidings and allthe specialty patterns from 4-inches wide to12-inches wide,” said Linton. “We producebevel siding inboth plain andrabbeted fromour state-ofthe-artequipment.In plainbevel we offer11/16-inchthick in 6-inchand 8-inchwidths, as wellas 3/4 and 7/8-inch thick in 6-,8-and 10-inchwidths. Therabbeted bevelis manufacturedin all thesame dimensionsas abovealong with 5/4-Sales manager Terry Baker inch in 6, 8, 10and 12-inchwidths,” saidVice President Ron Cluster.“The slight improvements we have seen inbusiness this year have allowed us to bringsome projects that would have otherwiseb e e nshelved,to thetable,”Lintonexplained.“ F o rexample,w einstalled an e wweightscale ato u rOldtownfacility andupgradedthe planerLance Hubener heads up sales atTri-Pro TM .mill inOrifino.W e ʼ v ealso madeadditionalimprovementsto our rolling stock at both facilities.Our claim to fame has been and always willbe the specialties, which we are known for.We feel it is important for us to keep ourcurrent and future customers supplied withhigh quality Cedar products from a consistentproducer that they can count on tokeep doing it and doing it right. And with thelarge log mill we are able to do a wideassortment of specialty products from allthe species we produce.”For more information about Tri-Pro ForestProducts visit www.triproforest.com or call(208) 437-2412.•PLEASE VISIT US ATNAWLA BOOTH NO. 807