Materials Science and Engineering Laboratory FY 2004 ... - NIST

Materials Science and Engineering Laboratory FY 2004 ... - NIST

Materials Science and Engineering Laboratory FY 2004 ... - NIST

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Highlights<br />

Profiling the Photoresist-Liquid Interface: Fundamentals<br />

for Immersion Lithography <strong>and</strong> Polymer Dissolution<br />

Recent advancements in the semiconductor<br />

industry have resulted in new problems involving<br />

the photoresist-liquid interface. For immersion<br />

lithography, the water profile within a resist film<br />

impacts pattern quality from changes in photoacid<br />

generator diffusion or optical transparency.<br />

For the development step, where a latent image<br />

is realized into the final structure, an improved<br />

underst<strong>and</strong>ing of photoresist swelling <strong>and</strong><br />

dissolution mechanisms is needed to address<br />

stringent line-edge roughness requirements.<br />

Data from neutron reflectivity measurements<br />

provide critical insight needed to underst<strong>and</strong><br />

<strong>and</strong> optimize next-generation photoresists <strong>and</strong><br />

process strategies.<br />

Bryan D. Vogt <strong>and</strong> Vivek M. Prabhu<br />

Introduction<br />

Polymer thin film photoresists comprise the materials<br />

foundation for the production of semiconductor<br />

devices with nanoscale dimensions. The extension of<br />

optical methods has been problematic due to challenges<br />

arising from the implementation of shorter exposure<br />

wavelengths. The past focus of the semiconductor<br />

industry has been the development of sufficiently<br />

transparent photoresist materials for future exposure<br />

sources. However, future progress requires depth<br />

profile information at the photoresist–liquid interface,<br />

due to the emergence of immersion lithography <strong>and</strong><br />

the increased influence of the photoresist development<br />

process on lithographic performance.<br />

Using neutron reflectivity (NR), <strong>NIST</strong> successfully<br />

quantified the profile of water <strong>and</strong> aqueous base<br />

counterions in model photoresist films. NR provides<br />

structural information regarding the composition<br />

profile normal to the thin-film surface with isotopic<br />

selectivity between protons <strong>and</strong> deuterium. Selective<br />

deuteration of components in the system allows for<br />

the quantification of water or counterion distribution<br />

within photoresist films despite the negligible<br />

differences in physical density. This data provide<br />

critical insight needed to refine models for immersion<br />

lithography <strong>and</strong> polymer dissolution.<br />

Immersion Lithography: Water Profile<br />

Recently, immersion lithography has emerged<br />

as the key strategy to extend existing optical tools.<br />

A liquid, such as water, is placed between the lens<br />

<strong>and</strong> photoresist thin film to enhance resolution.<br />

6<br />

The industry anticipates using immersion lithography<br />

for production in 2007 at the 65 nm node. The role of<br />

liquids in contact with photoresist films is important;<br />

not only for component leaching <strong>and</strong> contamination,<br />

but also due to the detrimental influence of trace levels<br />

of water on the reaction <strong>and</strong> diffusion of photoacid<br />

generators. Additionally, a non-uniform water profile<br />

within thin films leads to incorrect assumptions<br />

regarding the transmission <strong>and</strong> reflection at the<br />

photoresist–anti-reflective coating interface.<br />

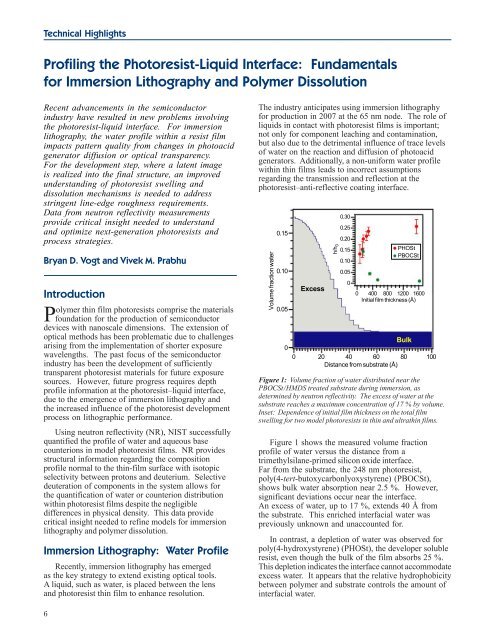

Figure 1: Volume fraction of water distributed near the<br />

PBOCSt/HMDS treated substrate during immersion, as<br />

determined by neutron reflectivity. The excess of water at the<br />

substrate reaches a maximum concentration of 17 % by volume.<br />

Inset: Dependence of initial film thickness on the total film<br />

swelling for two model photoresists in thin <strong>and</strong> ultrathin films.<br />

Figure 1 shows the measured volume fraction<br />

profile of water versus the distance from a<br />

trimethylsilane-primed silicon oxide interface.<br />

Far from the substrate, the 248 nm photoresist,<br />

poly(4-tert-butoxycarbonlyoxystyrene) (PBOCSt),<br />

shows bulk water absorption near 2.5 %. However,<br />

significant deviations occur near the interface.<br />

An excess of water, up to 17 %, extends 40 Å from<br />

the substrate. This enriched interfacial water was<br />

previously unknown <strong>and</strong> unaccounted for.<br />

In contrast, a depletion of water was observed for<br />

poly(4-hydroxystyrene) (PHOSt), the developer soluble<br />

resist, even though the bulk of the film absorbs 25 %.<br />

This depletion indicates the interface cannot accommodate<br />

excess water. It appears that the relative hydrophobicity<br />

between polymer <strong>and</strong> substrate controls the amount of<br />

interfacial water.