Materials Science and Engineering Laboratory FY 2004 ... - NIST

Materials Science and Engineering Laboratory FY 2004 ... - NIST

Materials Science and Engineering Laboratory FY 2004 ... - NIST

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

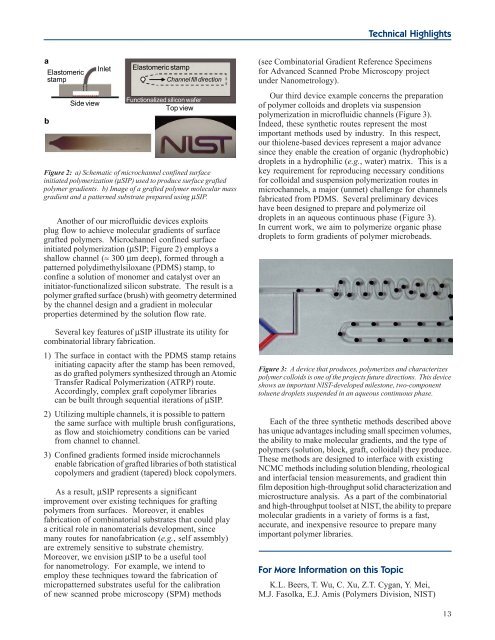

Figure 2: a) Schematic of microchannel confined surface<br />

initiated polymerization (µSIP) used to produce surface grafted<br />

polymer gradients. b) Image of a grafted polymer molecular mass<br />

gradient <strong>and</strong> a patterned substrate prepared using µSIP.<br />

Another of our microfluidic devices exploits<br />

plug flow to achieve molecular gradients of surface<br />

grafted polymers. Microchannel confined surface<br />

initiated polymerization (µSIP; Figure 2) employs a<br />

shallow channel (≈ 300 µm deep), formed through a<br />

patterned polydimethylsiloxane (PDMS) stamp, to<br />

confine a solution of monomer <strong>and</strong> catalyst over an<br />

initiator-functionalized silicon substrate. The result is a<br />

polymer grafted surface (brush) with geometry determined<br />

by the channel design <strong>and</strong> a gradient in molecular<br />

properties determined by the solution flow rate.<br />

Several key features of µSIP illustrate its utility for<br />

combinatorial library fabrication.<br />

1) The surface in contact with the PDMS stamp retains<br />

initiating capacity after the stamp has been removed,<br />

as do grafted polymers synthesized through an Atomic<br />

Transfer Radical Polymerization (ATRP) route.<br />

Accordingly, complex graft copolymer libraries<br />

can be built through sequential iterations of µSIP.<br />

2) Utilizing multiple channels, it is possible to pattern<br />

the same surface with multiple brush configurations,<br />

as flow <strong>and</strong> stoichiometry conditions can be varied<br />

from channel to channel.<br />

3) Confined gradients formed inside microchannels<br />

enable fabrication of grafted libraries of both statistical<br />

copolymers <strong>and</strong> gradient (tapered) block copolymers.<br />

As a result, µSIP represents a significant<br />

improvement over existing techniques for grafting<br />

polymers from surfaces. Moreover, it enables<br />

fabrication of combinatorial substrates that could play<br />

a critical role in nanomaterials development, since<br />

many routes for nanofabrication (e.g., self assembly)<br />

are extremely sensitive to substrate chemistry.<br />

Moreover, we envision µSIP to be a useful tool<br />

for nanometrology. For example, we intend to<br />

employ these techniques toward the fabrication of<br />

micropatterned substrates useful for the calibration<br />

of new scanned probe microscopy (SPM) methods<br />

Technical Highlights<br />

(see Combinatorial Gradient Reference Specimens<br />

for Advanced Scanned Probe Microscopy project<br />

under Nanometrology).<br />

Our third device example concerns the preparation<br />

of polymer colloids <strong>and</strong> droplets via suspension<br />

polymerization in microfluidic channels (Figure 3).<br />

Indeed, these synthetic routes represent the most<br />

important methods used by industry. In this respect,<br />

our thiolene-based devices represent a major advance<br />

since they enable the creation of organic (hydrophobic)<br />

droplets in a hydrophilic (e.g., water) matrix. This is a<br />

key requirement for reproducing necessary conditions<br />

for colloidal <strong>and</strong> suspension polymerization routes in<br />

microchannels, a major (unmet) challenge for channels<br />

fabricated from PDMS. Several preliminary devices<br />

have been designed to prepare <strong>and</strong> polymerize oil<br />

droplets in an aqueous continuous phase (Figure 3).<br />

In current work, we aim to polymerize organic phase<br />

droplets to form gradients of polymer microbeads.<br />

Figure 3: A device that produces, polymerizes <strong>and</strong> characterizes<br />

polymer colloids is one of the projects future directions. This device<br />

shows an important <strong>NIST</strong>-developed milestone, two-component<br />

toluene droplets suspended in an aqueous continuous phase.<br />

Each of the three synthetic methods described above<br />

has unique advantages including small specimen volumes,<br />

the ability to make molecular gradients, <strong>and</strong> the type of<br />

polymers (solution, block, graft, colloidal) they produce.<br />

These methods are designed to interface with existing<br />

NCMC methods including solution blending, rheological<br />

<strong>and</strong> interfacial tension measurements, <strong>and</strong> gradient thin<br />

film deposition high-throughput solid characterization <strong>and</strong><br />

microstructure analysis. As a part of the combinatorial<br />

<strong>and</strong> high-throughput toolset at <strong>NIST</strong>, the ability to prepare<br />

molecular gradients in a variety of forms is a fast,<br />

accurate, <strong>and</strong> inexpensive resource to prepare many<br />

important polymer libraries.<br />

For More Information on this Topic<br />

K.L. Beers, T. Wu, C. Xu, Z.T. Cygan, Y. Mei,<br />

M.J. Fasolka, E.J. Amis (Polymers Division, <strong>NIST</strong>)<br />

13