Materials Science and Engineering Laboratory FY 2004 ... - NIST

Materials Science and Engineering Laboratory FY 2004 ... - NIST

Materials Science and Engineering Laboratory FY 2004 ... - NIST

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

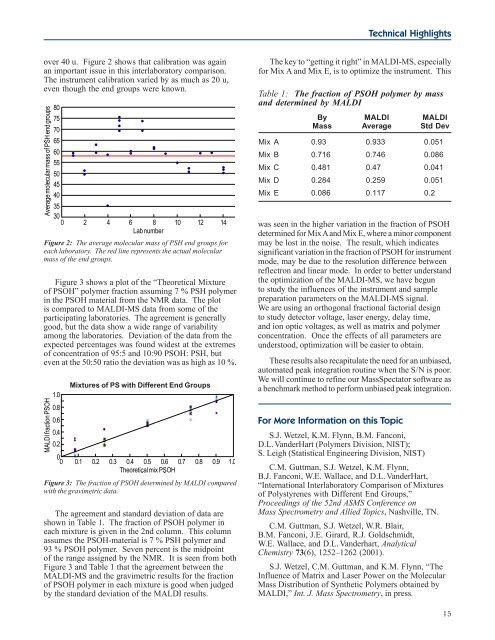

over 40 u. Figure 2 shows that calibration was again<br />

an important issue in this interlaboratory comparison.<br />

The instrument calibration varied by as much as 20 u,<br />

even though the end groups were known.<br />

Figure 2: The average molecular mass of PSH end groups for<br />

each laboratory. The red line represents the actual molecular<br />

mass of the end groups.<br />

Figure 3 shows a plot of the “Theoretical Mixture<br />

of PSOH” polymer fraction assuming 7 % PSH polymer<br />

in the PSOH material from the NMR data. The plot<br />

is compared to MALDI-MS data from some of the<br />

participating laboratories. The agreement is generally<br />

good, but the data show a wide range of variability<br />

among the laboratories. Deviation of the data from the<br />

expected percentages was found widest at the extremes<br />

of concentration of 95:5 <strong>and</strong> 10:90 PSOH: PSH, but<br />

even at the 50:50 ratio the deviation was as high as 10 %.<br />

Mixtures of PS with Different End Groups<br />

Figure 3: The fraction of PSOH determined by MALDI compared<br />

with the gravimetric data.<br />

The agreement <strong>and</strong> st<strong>and</strong>ard deviation of data are<br />

shown in Table 1. The fraction of PSOH polymer in<br />

each mixture is given in the 2nd column. This column<br />

assumes the PSOH-material is 7 % PSH polymer <strong>and</strong><br />

93 % PSOH polymer. Seven percent is the midpoint<br />

of the range assigned by the NMR. It is seen from both<br />

Figure 3 <strong>and</strong> Table 1 that the agreement between the<br />

MALDI-MS <strong>and</strong> the gravimetric results for the fraction<br />

of PSOH polymer in each mixture is good when judged<br />

by the st<strong>and</strong>ard deviation of the MALDI results.<br />

Technical Highlights<br />

The key to “getting it right” in MALDI-MS, especially<br />

for Mix A <strong>and</strong> Mix E, is to optimize the instrument. This<br />

Table 1: The fraction of PSOH polymer by mass<br />

<strong>and</strong> determined by MALDI<br />

By MALDI MALDI<br />

Mass Average Std Dev<br />

Mix A 0.93 0.933 0.051<br />

Mix B 0.716 0.746 0.086<br />

Mix C 0.481 0.47 0.041<br />

Mix D 0.284 0.259 0.051<br />

Mix E 0.086 0.117 0.2<br />

was seen in the higher variation in the fraction of PSOH<br />

determined for Mix A <strong>and</strong> Mix E, where a minor component<br />

may be lost in the noise. The result, which indicates<br />

significant variation in the fraction of PSOH for instrument<br />

mode, may be due to the resolution difference between<br />

reflectron <strong>and</strong> linear mode. In order to better underst<strong>and</strong><br />

the optimization of the MALDI-MS, we have begun<br />

to study the influences of the instrument <strong>and</strong> sample<br />

preparation parameters on the MALDI-MS signal.<br />

We are using an orthogonal fractional factorial design<br />

to study detector voltage, laser energy, delay time,<br />

<strong>and</strong> ion optic voltages, as well as matrix <strong>and</strong> polymer<br />

concentration. Once the effects of all parameters are<br />

understood, optimization will be easier to obtain.<br />

These results also recapitulate the need for an unbiased,<br />

automated peak integration routine when the S/N is poor.<br />

We will continue to refine our MassSpectator software as<br />

a benchmark method to perform unbiased peak integration.<br />

For More Information on this Topic<br />

S.J. Wetzel, K.M. Flynn, B.M. Fanconi,<br />

D.L. V<strong>and</strong>erHart (Polymers Division, <strong>NIST</strong>);<br />

S. Leigh (Statistical <strong>Engineering</strong> Division, <strong>NIST</strong>)<br />

C.M. Guttman, S.J. Wetzel, K.M. Flynn,<br />

B.J. Fanconi, W.E. Wallace, <strong>and</strong> D.L. V<strong>and</strong>erHart,<br />

“International Interlaboratory Comparison of Mixtures<br />

of Polystyrenes with Different End Groups,”<br />

Proceedings of the 52nd ASMS Conference on<br />

Mass Spectrometry <strong>and</strong> Allied Topics, Nashville, TN.<br />

C.M. Guttman, S.J. Wetzel, W.R. Blair,<br />

B.M. Fanconi, J.E. Girard, R.J. Goldschmidt,<br />

W.E. Wallace, <strong>and</strong> D.L. V<strong>and</strong>erhart, Analytical<br />

Chemistry 73(6), 1252–1262 (2001).<br />

S.J. Wetzel, C.M. Guttman, <strong>and</strong> K.M. Flynn, “The<br />

Influence of Matrix <strong>and</strong> Laser Power on the Molecular<br />

Mass Distribution of Synthetic Polymers obtained by<br />

MALDI,” Int. J. Mass Spectrometry, in press.<br />

15