Ryan NYP NX211 - Macca's Vintage Aerodrome

Ryan NYP NX211 - Macca's Vintage Aerodrome

Ryan NYP NX211 - Macca's Vintage Aerodrome

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

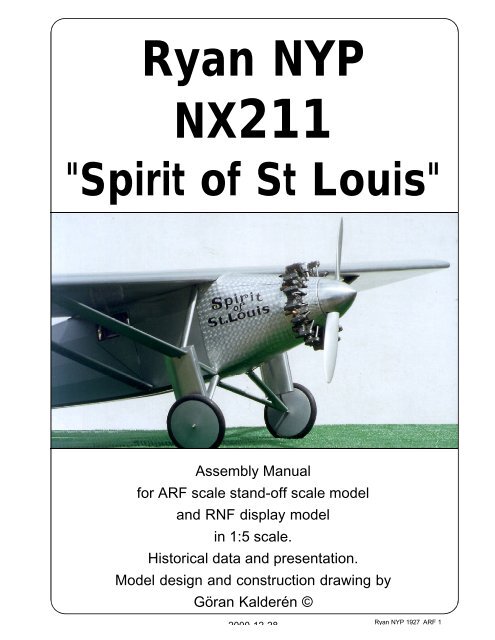

<strong>Ryan</strong> <strong>NYP</strong><br />

<strong>NX211</strong><br />

"Spirit of St Louis"<br />

Assembly Manual<br />

for ARF scale stand-off scale model<br />

and RNF display model<br />

in 1:5 scale.<br />

Historical data and presentation.<br />

Model design and construction drawing by<br />

Göran Kalderén ©<br />

2000-12-28<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 1

First Nonstop Solo Transatlantic Flight<br />

On May 21, 1927, the son of a Swedish<br />

immigrant, Charles A. Lindbergh completed the<br />

first solo non stop transatlantic flight in history.<br />

He flew his special built <strong>Ryan</strong> <strong>NYP</strong> “Spirit of<br />

St.Louis” 5,810 kilometers (3,610 miles) from<br />

Roosevelt Field on Long Island, New York to le<br />

Bourget airfield outside Paris, France in 33 hours<br />

and 30 minutes. With this achievement<br />

Lindbergh won the $25,000.- prize offered by the<br />

New York hotel owner Raymond Orteig to the<br />

first aviator to fly directly across the Atlantic from<br />

New York to Paris.. Charles Lindbergh became<br />

a world hero who would remain in the public eye<br />

for decades to follow.<br />

The aftermath of the flight was the<br />

“Lindbergh boom” in aviation. Aircraft industry<br />

stock rose in value and the interest in flying<br />

zoomed. Lindbergh’s subsequent tour in the<br />

“Spirit of St. Louis” demonstrated the airplane<br />

as a safe and reliable mode of transportation.<br />

Following the US tour he took the airplane on a<br />

goodwill tour to South and Central America. The<br />

flags of the countries that he visited were painted<br />

on the engine cowling.<br />

“Spirit of St. Louis” was named in honor<br />

of the supporters in St.Louis, who paid for the<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 2<br />

aircraft. “<strong>NYP</strong>” is the acronym for “New York-<br />

Paris”, the object of the flight.<br />

Design features<br />

The “Spirit of St. Louis” was designed by Donald<br />

Hall under the direct supervision of Charles<br />

Lindbergh. It is a highly modified version of a<br />

conventional <strong>Ryan</strong> M-2 strut-braced high wing<br />

monoplane, powered by a reliable Wright J-5C<br />

9 cylinder radial engine. Because the fuel tanks<br />

were located ahead of the cockpit for safety in<br />

case of an accident, the forward view was<br />

restricted or rather non-existent. Lindbergh could<br />

not see directly ahead but he could peek out<br />

through the open side windows or use a<br />

periscope mounted in his forward field of vision.<br />

Development<br />

<strong>NYP</strong> was an extensively modified M-2. The<br />

aircraft first flew on April 28, 1927. Between May<br />

10 and May 12 Lindbergh flew the plane from<br />

San Diego to New York in 21 hours and 40<br />

minutes, setting a new transcontinental record.<br />

The aircraft made its last flight on April 30, 1928<br />

when it arrived at the National Air and Space<br />

Museum in Washington DC, where it still resides<br />

today.<br />

Data<br />

Wingspan: 14 m (46 ft.)<br />

Length: 8 m (27 ft 8 in)<br />

Height: 3 m ( 9 ft 10 in)<br />

Wing area: 29,7 sq.m<br />

Weight gross: 2,330 kg (5,135 lb)<br />

Weight empty: 975 kg (2,150 lb)<br />

Engine: Wright Whirwind J-5C, 223hp<br />

Max. speed: 210 km/h<br />

Cruise speed: 180 km/h<br />

Ceiling: 5000 m<br />

Range: 6600 km<br />

Manufacturer: <strong>Ryan</strong> Airlines Co. San Diego,CA.<br />

Crew: 1

The original "Spirit of St. Louis" aircraft in the National<br />

Air & Space Museum in Waschington DC.<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 3

A replica built in France and now residing in the EAA Museum in Oskosh, U.S.A.<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 4

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 5

The Model<br />

I have chosen the scale 1:5, as it gives a reasonable<br />

big airplane but small enough to handle in a car,<br />

easy to assemble at the airfield and above all, is<br />

relatively forgiving to fly.<br />

The airplane comes with the tailskid attached and<br />

it remains only to attach the landing gear, the<br />

stabilizer in place and attach the fin and the rudder,<br />

control wires to the rudder and elevator horns. The<br />

stabilizer is supported by struts as by the full scale<br />

prototype. The elevator and rudder are actuated<br />

with pull-pull wires, which is scale and very reliable.<br />

The wires are attached directly to the rudder bar<br />

and the elevator control column.<br />

The wing halves are joined together with 5 mm<br />

spring steel rods in holes located in the wing root.<br />

The whole wing is placed on top of the fuselage<br />

and bolted to the frame with 4 Allen bolts. The wing<br />

struts are functional and are attached to the wings<br />

and fuselage (landing gear) with 3 mm screws and<br />

lock nuts.<br />

Specification<br />

Wingspan: 2800 mm 112"<br />

Length: 1600 mm 64"<br />

Wing surface: 119 dm² 1500 sq”<br />

Wing loading: 60 gm/dm² 16.2 oz/sq’<br />

Weight: 7200 gm 15 lb. 9oz.<br />

Engine: .60/.80 2-stroke or .90/1.20 4stroke<br />

For display version disregard sections marked<br />

with *<br />

*Engine installation<br />

The engine is installed upright in the plywood engine<br />

bearers. The cut-out is made for a 1..20 4-stroke<br />

engine. We used a Saito 1.20 engine in our<br />

prototype. A right thrust of 2-3° is recommended<br />

to compensate for the torque. We flew our<br />

prototype with 1° right thrust with additional rudder<br />

correction at full speed. In full size manner you<br />

can add side deflection on the fin instead of engine<br />

thrust deflection.<br />

Rudder and<br />

elevator servo<br />

linkages<br />

Elevator servo<br />

linkage<br />

Rudder cables<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 6<br />

Rudder<br />

servo<br />

linkage<br />

Remove the center upright dummy engine cylinder<br />

and parts of the crankcase. You will have to enlarge<br />

the openings in the aluminum covering plates<br />

depending on what engine you are installing.<br />

Where wood is removed, smoothen the surfaces<br />

and coat the whole interior with fuel proof paint.<br />

Lead the throttle cable to the servo through a hole<br />

in the firewall and connect the fuel tube from your<br />

tank to the carburettor.<br />

The tank is placed on the engine bearer board in<br />

the compartment behind the engine. This brings<br />

the tank level with the carburettor.<br />

*Special order version with vertical firewall<br />

Should you wish to install a radial engine like the<br />

Technopower 9 cylinder, 1/5th scale, here are the<br />

essential measurments for this installation.<br />

Dummy engine diameter 235 mm / 9.3”<br />

Firewall diameter 165 mm / 6.5”<br />

Spinner backplate 115 mm / 4.5”<br />

Distance firewall to spinner 75 mm / 3”<br />

*Radio/servo installation<br />

The receiver and battery are located on the upper<br />

tray behind the fire wall above the tank.<br />

The servos for rudder, elevator and throttle are<br />

affixed in the servo tray with special screws and<br />

Location of tank and<br />

throttle servo in<br />

fuselage<br />

Location<br />

of<br />

tank<br />

Rudder<br />

and elevator<br />

servos<br />

Location of<br />

Elevator<br />

cables

grommets. The ailreon servos (2) are located in<br />

the wing root of the wings.<br />

Rudder and elevator surfaces are controlled with<br />

cables from the rudderbar and the control column.<br />

Fuselage<br />

The fuselage is completely built up. It is complete<br />

with pulleys and all control wires attached. The<br />

stabilizer and fin must be attached to the fuselage<br />

and the wing appropriately affixed to the fuselage.<br />

Landing gear<br />

The landing gear has to be attached to the fuselage<br />

at the 6 attachment pionts using 3 mm screws<br />

and locknuts.<br />

1. First install the support angle at the side of the<br />

fuselage with 3 mm screws and locknuts. The open<br />

"fork" should be directed downward.<br />

2. Install the landing gear legs in the brackets in<br />

the lower part of the fuselage with 3 mm screws<br />

and locknuts.<br />

3. Connect the landing gear with the angular<br />

support with 3 mm screws and locknuts. Make<br />

sure that the longer rod of the oleo strut connects<br />

with the landing gear leg. Tighten the nuts enough<br />

to let the landing gear and the oleo strut move freely.<br />

4. Replace the aluminum cover and secure with<br />

#2 x 1/4" screws. See detail sketch for reference.<br />

The oleo struts are functional and the rubber band<br />

should be replaced when worn out.We have<br />

Main<br />

landing gear<br />

oleo strut<br />

support<br />

Rear landing<br />

gear leg<br />

Front landing<br />

gear leg<br />

Landing gear and wing strut support<br />

The oleo strut is first attached to the upper landing gear support.<br />

The aluminum cover plate is then pushed up from the bottom. Secure the cover plate with #2<br />

sheet metal screws. Then attach the lower end of the oleo strut to the landing gear shaft. For<br />

the entire landing gear assembly use 3 mm screws and lock nuts<br />

Rear wing strut<br />

Front wing strut<br />

Oleo strut with<br />

attachment pegs<br />

for bungee rubber<br />

Wheel<br />

collar<br />

Balsa strut<br />

fairing<br />

Front landing<br />

gear leg<br />

Oleo strut cover plate<br />

Landing gear and<br />

front wing strut support<br />

Landing gear and front<br />

wing strut support bracing.<br />

Same bolt as strut<br />

attachmentpoint<br />

Oleo strut with<br />

attachment pegs<br />

for bungee rubber<br />

Wing struts are made of flat<br />

steel faired with balsa. End<br />

fittings are heavy duty brass.<br />

The struts are attached to the<br />

fuselage and the wings with 3<br />

mm screws and locknuts.<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 7

installed a fresh set of rubber bands before<br />

shipment.<br />

Covered wooden wheels with tires are supplied.<br />

Spoked wheels are optional and available as extra<br />

parts. Secure the wheel collars with the 3 mm Allen<br />

set screws such that the wheels can turn freely<br />

and use Locktite or similar to secure the wheel<br />

collars.<br />

Stabilizer / elevator<br />

The stabilizer is attached to the fuselage with 3<br />

nylon screws. The stabilizer is secured with 3 preadjusted<br />

struts, attached with #2 screws to the<br />

fuselage.<br />

Attach the elevator wires from the elevator servo<br />

arm to the elevator horn. The elevator wires exit<br />

through holes in the rear of the fuselage and the<br />

upper wires pass through the stabilizer. Note that<br />

the wires are crossed in the fuselage so that the<br />

lower wire at the control column attaches to the<br />

upper horn on the elevator. Elevator deflection<br />

should be 20° up and down.<br />

Fin / rudder<br />

The fin and rudder with hinges is pushed in to the<br />

supporting tube in the fuselage. It is locked with 1<br />

#2 screw into the outer tube. The only remaining<br />

thing is to attach the rudder wires to the rudder.<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 8<br />

Hinge<br />

pins<br />

The rudder wires exit through holes in the rear of<br />

the fuselage. Rudder deflection should be 30° left<br />

and right.<br />

Wings<br />

The wing halves are joined together with 5 mm<br />

spring steel rods. The two aileron servos are<br />

installed in the servo mounts in he underside of<br />

the wings in the cabin area and connected to the<br />

push-pull aileron bellcrank. Pull-pull wires lead out<br />

to the ailerons via pulleys in front of the ailerons<br />

(scale function). Check the throw and function by<br />

temporarily connecting the servos to the radio. The<br />

complete wing is now placed on top of the fuselage<br />

with the window in the center. Four 5 mm Allen<br />

bolts secure the wing to the fuselage.<br />

Now the wing struts are installed with 3<br />

mm screws and locking nuts. The wingstruts are<br />

functional and has to be checked for security.<br />

Access to the inside of the cabin is through the<br />

door and the port side window. No clear panels<br />

were installed in the side windows of the original<br />

aircraft.<br />

*Finishing<br />

The model is covered with Solartex aluminum and<br />

all markings are painted with Dutch Boy black<br />

enamel.<br />

Installation of fin, rudder, stabilizer and elevator<br />

Fin front<br />

support bracket<br />

Screw for<br />

locking fin post<br />

to fuselage<br />

Elevator<br />

cables<br />

Stabilizer attachment<br />

screws ( 3 pcs nylon)

Aileron<br />

cables<br />

Aileron<br />

cables<br />

Aileron servo linkage<br />

Aileron<br />

servo Servo to<br />

bellcrank<br />

link<br />

Aileron<br />

bellcrank<br />

We suggest that you paint all wooden<br />

surfaces in the engine bay with one coat of clear<br />

fuel-proofing. Also on the areas where you have<br />

removed parts of the dummy engine to fit the flying<br />

engine in place.<br />

*Dummy engine<br />

A dummy of the Wright J-5, 9 cylinder<br />

engine is is supplied and has to be removed and<br />

remodeled to fit with your engine for flying. You can<br />

attach the dummy engine to the engine mount after<br />

removing one cylinder in lieu of the real engine.<br />

You may also have to make a cut-out in the upper<br />

aluminum nose panel. It is recommended to let<br />

the exhaust out via a flexible header end exit<br />

through the lowel nose cowl panel. There is plenty<br />

of room for the silencer inside the cowling. The<br />

above refers to the installation of a 1.20 4-stroke<br />

engine. We installed a Saito engine which has<br />

rocker covers closely resembling the Wright J-5.<br />

Scale propeller<br />

A finished scale propeller with spinner and spinner<br />

mounting plate is supplied. The hole is drilled for<br />

6,5 mm propeller shaft and may have to be<br />

enlarged to fit your engine. The spinner is attached<br />

to the backplate with 4 #2 screws. This propeller<br />

Aileron<br />

break<br />

pulleys<br />

Aileron<br />

horn<br />

Location of<br />

wing<br />

mounting<br />

bolts<br />

Aileron servo<br />

installation<br />

Aileron servo and<br />

aileron bellcrank<br />

seen from the top<br />

of the wing<br />

is not intended for flying. You can replace the<br />

propeller with one suitable for your engine. The<br />

attachment of the spinner cone with the #2 screws<br />

will however be subject to adding lockwashers to<br />

prevent the screws from loosening. Best is to<br />

acquire a 4½" aluminum spinner with central<br />

attachment screw for flying.<br />

*Balancing<br />

The airplane should balance at a point in the range<br />

of 9 -11cm (3.6"-4.4") wich is equal to 20 - 25% of<br />

the wing cord from the leading edge. Move the<br />

battery or add weight if required. A setting further<br />

forward will make the aircraft "groovy".<br />

Pitot tube and Windgenerator<br />

For transport reaseons both the long pitot tube and<br />

the windgeneratoror vane are separated from the<br />

model and packed separately. The pitot tube fits<br />

on the underside of the left wing just outside the<br />

wingstruts. Push the assembly gently but firmly<br />

into the 2 holes in the wing. The windgenerator<br />

vane is pushed into the hole on the top of the<br />

fuselage. Two ballbearings will enable the free<br />

turning of the vane. Friction will hold the vane axle<br />

in place.<br />

*Flying<br />

Make sure that you have set the elevator throw as<br />

recommended. Check also that the wings are level<br />

and have the proper wash out.<br />

Take off with this airplane is straight into the wind<br />

only. Don’t try to pull it of the ground. Let it lift off<br />

gently. Make the turns with coordinated rudder/<br />

elevator and aileron. It is not a pattern airplane!<br />

Remember that this airplane was built for a specific<br />

purpose; with a very high payload of fuel to cross<br />

the Atlantic Ocean from New York to Paris.<br />

The stabilizer area is relatively small but the<br />

moment arm long. Keep the speed up when you<br />

come in for landing. Enjoy cruising in the blue sky<br />

and feel the thrill of the imaginative re-enacting of<br />

the acomplishment of a successful early aviator.<br />

Happy and safe landings!<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 9

The left side<br />

landing gear<br />

with the<br />

streamlined<br />

covering removed<br />

The wing is attached with 4 Allen bolts. The<br />

window on top of the cockpit is an intergral<br />

part of the fuselage.<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 10<br />

The <strong>Ryan</strong> <strong>NYP</strong> before covering, painting and finishing<br />

The wing<br />

struts are<br />

functional<br />

Bungee<br />

rubber<br />

bands<br />

The <strong>Ryan</strong> <strong>NYP</strong> is constructed closely to<br />

the principles of the full size aircraft. The landing<br />

gear is fully functional with rubber bungee bands<br />

as chock absorber. The wing struts are functional<br />

and consist of steel straps, faired with balsa as<br />

on the full size original.<br />

The landing gear is constructed of heavy<br />

duty 5 mm steel spring steel wire to withstand<br />

the hardships of a not so good landings.<br />

The ailerons are activated by pull-pull<br />

wires from a bellcrank in the wing root to the<br />

aileron horns. The servos (2) are coupled with a<br />

short links to these bellcranks. The rudder and<br />

the elevator are connected with pul-pull wires in<br />

scale fashion and the control column as well as<br />

the rudder bar are connected to the servos with<br />

short links with ball links in one end. This gives a<br />

very positive and smoth action. The throw can<br />

be increased or decreased according to taste.<br />

The ailerons can also be set for differential throw<br />

(more up than down movement), recommended<br />

for the average skilled pilot.<br />

The engine installation is straight forward<br />

and the required cut-outs have to be made on<br />

the aluminum cover plates to accomodate the<br />

flying engine. The spinner has aluminum<br />

backplate and can be used for flying. The scale<br />

propeller has to be replaced for flying.

The right side landing gear has the<br />

streamlined covering installed<br />

The engine for flying (Saito 1.20 4-stroke) blends<br />

very inconspiciously with the dummy<br />

Wright Cyclone J-5 engine. The<br />

spinner is scale with<br />

display propeller<br />

A generous wing area renders low wing loading<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 11

What is in the box:<br />

The ARF kit contains the parts shown in the picture.<br />

All the parts are covered and painted. All the rigging<br />

3<br />

9<br />

K&W<br />

4<br />

1. Fuselage with tail skid.<br />

2. Landing gear assembly<br />

3. Scale wheels<br />

Model<br />

Airplanes Inc.<br />

<strong>Ryan</strong> <strong>NYP</strong> 1927 ARF 12<br />

8<br />

1<br />

2<br />

wires are supplied in the correct lengths and need<br />

only to be clipped to their positions.<br />

5 6<br />

4. Dummy engine with mount<br />

5. Scale propeller with spinner<br />

6. Fin / rudder<br />

7<br />

P.O.Box 1229, Cebu City Centrl. Postoffice<br />

Cebu City 6000, Philippines<br />

Visiting address:<br />

3343 Gun-Ob, Kinalumsan,<br />

Lapu-Lapu City 6015, PHILIPPINES<br />

Phone +63 32-340 7147, Cellular +63 917-3200 985<br />

Telefax +63 32-340 7131, E-mail: kwmairpl@gsilink.com<br />

8<br />

10<br />

7. Stabilizer / elevator<br />

8. Wing panels<br />

9. Wing struts<br />

10. Assembly manual