Download PDF Manual - Macca's Vintage Aerodrome

Download PDF Manual - Macca's Vintage Aerodrome

Download PDF Manual - Macca's Vintage Aerodrome

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

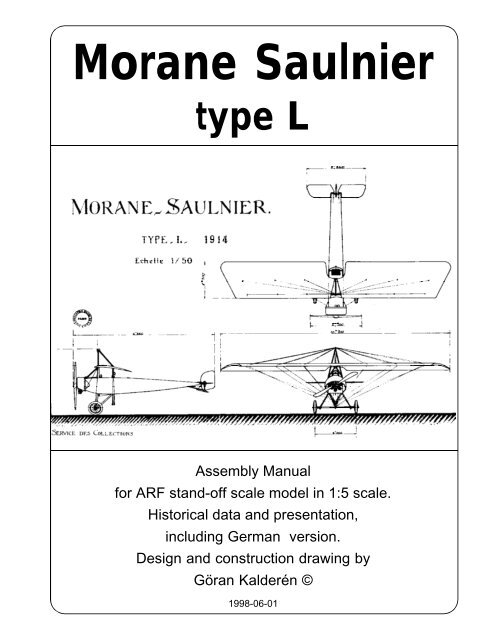

Morane Saulnier<br />

type L<br />

Assembly <strong>Manual</strong><br />

for ARF stand-off scale model in 1:5 scale.<br />

Historical data and presentation,<br />

including German version.<br />

Design and construction drawing by<br />

Göran Kalderén ©<br />

1998-06-01

Morane-Saulnier type L<br />

Roland Garros gave this aeroplane fame<br />

in that he flew the first MS type L with a Hotchkiss<br />

machine gun and interrupter gear. He managed<br />

to shoot down one opponent before he himself<br />

was forced to land in enemy territory. The brilliant<br />

french solution of the interrupter gear was of<br />

course copied and improved by the germans and<br />

applied on the better known Fokker E III.<br />

Morane Saulnier type L was designed in<br />

1914, intended for surveillance and artillery observation.<br />

The placing of the wings in a parasol<br />

manner gave both the pilot and the observer an<br />

exellent downward view of the happenings<br />

below. For the benefit of forward and upward<br />

vision a sizeable cutout in the center wing panel<br />

was made.<br />

Also for the flying schools this was an<br />

excellent plane with inherent lateral stability and<br />

The flying school displaying numerous aircrafts.<br />

Morane Saulnier type L -ARF 2<br />

ease of control.<br />

The engine, a french Clerget rotary engine<br />

of 60 hp, gave adequate speed and a generous<br />

wing surface, satisfactory lift. Both the vertical<br />

and horizontal quidance was by all moving<br />

stabilator and rudder and the fuselage gave horizontal<br />

stability.<br />

Lateral control was by wing warping. The<br />

front wing spar is fixed by 6 upper-, landing wires<br />

and 6 lower- flying wires. The rear spar is<br />

controlled by wires running through a pulley in<br />

the topp wire support pylon and a actuator lever<br />

at the lower wire support pylon. The actuator i<br />

coupled to the control collumn by wires. Hence<br />

by moving the control collumn the wires are<br />

activated.<br />

The landing gear is tubular steel and the<br />

wheel shaft is supported with bungee rubbers.<br />

Note that the forward attachment point of the lan-<br />

Musée de l'Air, Paris Musée de l'Air, Paris

The german version, Pfalz E III, built under licence by Pfalz Flugzeugbau in Steyer, Germany.<br />

Deutsches Museum, München Deutsches Museum, München<br />

Deutsches Museum, München<br />

Morane Saulnier type L -ARF 3

ding gear struts varies from manufacturer to<br />

manufacturer. We have chosen the original<br />

french type for our model.<br />

Pictured is the aeroplane number 274, that<br />

possibly belonged to the same group as shown<br />

in the photo.<br />

The documentation available for the armament<br />

is only, the patent application that was<br />

granted 1914 to Raymond Saulnier. It is no more<br />

than a priciple sketch of the installation of the<br />

Hotchkiss machine gun and the innovative<br />

interrupter gear.<br />

The german company Pfalz Flugzeug Bau<br />

in Steyer, Germany, bought the licence for<br />

manufacturing and the pictures reveal the german<br />

thoroughness, displaying the fuselage construction<br />

in detail and a top view that gives the<br />

wing and tailplane outline.<br />

Caption on the back of the photograph:<br />

"Aircraft readied for land transport. Wings will<br />

be stored along the fuselage".<br />

The german model was photographed in<br />

1916...<br />

If you chose to model the german version,<br />

these pictures give you a fair orientation of the<br />

alterations. It should also be mentioned that the<br />

German crosses underwent noticable changes<br />

during the course of the war. From the original<br />

"Malteese cross" to a more strict angular.<br />

Also in Sweden this model was built under<br />

licence, designated Thulin type D. The swedish<br />

model was later improved with streamlining<br />

of the engine cowl - fuselage and fitted with a 95<br />

hp Thulin A rotary engine, a licence built Le<br />

Rhone engine.<br />

The swedish pioneer Enoch Thulin built<br />

the aircraft under licence, but he also improved<br />

the design, e.g. adding streamlining plywood<br />

panels from the engine cowl to the rear part of<br />

the cockpit.<br />

One aircraft was donated to Finland in<br />

1918 by the swedish count Eric von Rosen and<br />

became the first Finish military aircraft. The finish<br />

plane was endowned with the blue swastika<br />

cross, the crest of the von Rosen family, later to<br />

become the national insignia for Finland.<br />

The first licence built aircraft by Enoch Thulin in Sweden. Note the original design of the fuselage.<br />

Below the same aircraft exhibited in the Stockholm Trade Fair 1915.<br />

Morane Saulnier type L -ARF 4

Prototype specifications:<br />

Manufacturer: Morane-Saulnier Societé de<br />

Constructions Aeronautics, Paris, France.<br />

Length: 20 ft 9 in. Span: 34 ft. Area: 172 sq ft.<br />

Useful load: 550 lbs. Weight loaded: 820 lbs.<br />

Motor 80 hp Gnome rotary. Speed max: 76<br />

mph. Min: 55 mph. Climb rate: 345 ft per min.<br />

Morane Saulnier type L -ARF 5

Color details<br />

Most of the aircrafts had a "natural"<br />

finish. This means unbleached linnen fabric<br />

that was clear doped and then given a<br />

protective varnish finish that resulted in a<br />

yellowish (primrose) tint that bleached to a<br />

greyish-cream shade.<br />

Roundels were carried both above<br />

and below on the wings. Red was the outer<br />

circle, white and blue in the center. The<br />

rudder was divided into three equal fields<br />

with the blue foremost.<br />

Struts and landing gear were painted<br />

black. Wheel disks were black. Tires on<br />

some planes were white. There was also a<br />

black stripe all along the four corners of the<br />

fuselage. The plywood parts had varnished<br />

"natural" color. The access dor on the<br />

forward fuselage sides had black metal<br />

edging.<br />

The "MS" monogram was painted<br />

black on natural aluminum cowlings and<br />

white on black cowlings<br />

Morane Saulnier type L -ARF 6

The model<br />

Specs:Wingspan 220 cm 86,8"<br />

Length 138 cm 54,5"<br />

Wingarea 75,6 dm² 1080 sq"<br />

Weight 3,9 kgs8,6 lb<br />

Wing Loading 52 g / dm² 17 oz/sq'<br />

Engine 10 cc 2-stroke<br />

Although this model is designed with<br />

wing-warping, it can be flown with rudder and<br />

elevator, provided that you employ a wash-out<br />

at the wing tips of approx. 1" (25 mm). This is<br />

done at the moment of rigging.<br />

You have received this model ARF, that<br />

means all the pleasant work is left to be done by<br />

you.<br />

Covering and finish<br />

The model is covered and painted from<br />

the factory. When you have made changes in<br />

the fire wall and adapted the dummy engine to<br />

fit in front of the engine, you will have to cover<br />

the open areas with fuel proof paint.<br />

Installation of engine.<br />

The engine mounts have been installed<br />

in a unusual fashion for several reasons. The<br />

need for adequate cooling. The access to the<br />

glow plug without hole in the cowl and finally to<br />

get the carburator in line with the center of the<br />

tank.<br />

1. Remove the engine mounts and drill and tap<br />

the holes for the engine. Place the engine as<br />

close to the fire wall as possible. If you have to<br />

relocate the engine mounts, you can do so and<br />

the blind nuts are not secured with glue. Should<br />

you desire to install a 4-stroke engine you may<br />

have to make an opening in the firewall for the<br />

carburator and a small "box" so that no fuel<br />

spreads into the fuselage. On the full size plane,<br />

the carburator is licated between the two air<br />

intake tubes!<br />

2. Drill the holes from the tank to the carburator,<br />

preassure nipple and the filling cap.<br />

3. Install the engine and connect the throttle<br />

servo.<br />

4. Make cut outs in the dummy engine so that<br />

this will fit in front of your engine. You may have<br />

to remove 1 complete cylinder to allow for the<br />

cooling air to pass the engine head. This<br />

"surgery" is executed by removing a little at the<br />

time and checking. When you are satisfied with<br />

the fit and openings, screw the dummy engine<br />

onto the engine mounts using 3 mm screws and<br />

washers.<br />

5. Reinstall the engine cowl using 3 #2 sheet<br />

metal screws.<br />

Installation of servos, tank, battery and receiver.<br />

The aileron servo is installed in the servo mount<br />

in the bottom of the fuselage.<br />

The trottle servo and the rudder servo are<br />

installed in the lower servo tray. The tank is<br />

positioned crosswise in front of these servos.<br />

The elevator servo is is installed inverted in<br />

the upper tray.<br />

Battry pack and receiver are positioned in the<br />

upper tray.<br />

The switch is mounted on the dash board.<br />

1. Attach a ball link head to joystick and<br />

rudder bar in the appropriate holes. You may<br />

Morane Saulnier type L -ARF 7

have to enlarge the holes to take the screw from<br />

the ball link (Dubro #189 set of 2).<br />

2. Install the servos for rudder and<br />

elevator and temporarily connect the servo arms<br />

to the ball links. Deflection for elevator is 20° up<br />

and down and for rudder 30° right and left..<br />

3. Install and connect the throttle servo<br />

in the fashion you prefer.<br />

4. Install the tank in the available space in front<br />

of the rudder and throttle servos..<br />

5. Install the aileron servo in the lower<br />

part of the fuselage and connect the two wires<br />

from the warping actuator to the srvo arm. Use<br />

the cerulets provided. Stretch the wire and crimp<br />

the cerulets. Make sure that the servo arm and<br />

the actuator arm are parralell.<br />

6. Fasten the upper servo tray and make<br />

the final connections.<br />

7. Install the radio switch on the<br />

dashboard.<br />

8. Place the receiver and the battery<br />

pack in the upper tray, wrapped in foam rubber<br />

and secure with rubber bands.<br />

Assembly and rigging<br />

There are 30 pcs of rigging wire fittings<br />

consisting of 2 mm Ø threaded bar stock soldered<br />

to wire eylets. On each there is a 2 mm<br />

locking nut.<br />

Landing wires (top of the pylon) 6 pcs<br />

the rest have one kwick-link added.<br />

Flying wires 6 pcs<br />

Warping wires 12 pcs<br />

Elevator wires 4 pcs<br />

Rudder wires 2 pcs<br />

All wires are fixed at one of their locations and<br />

cut to proper length.<br />

Start with the control wires. The drawing<br />

indicates the location. Insert the wire with kwick<br />

link into the hole in the joy stick. The rudder wires<br />

ar fixed to the rudder bar and need only to be<br />

clipped onto the rudder horn. Note that the elevator<br />

wires are crossed in the fuselage.<br />

The wing rigging starts with the landing<br />

wires wich are fixed to the wings. Add the fittings<br />

to the tower threading a nut halfway in. Alternate<br />

left and right starting from the front / inner<br />

positions. Proceed as described earlier. Proceed<br />

with the flying wires, and attaching the fitting to<br />

the locations on the fuselage.<br />

The lower warping wires are fitted to pulleys.<br />

The upper wires are moving freely in the pulley.<br />

The lower wires are turned around and locked<br />

to the pulleys front and aft. Note that the inner<br />

lower warping wires are fixed to the fuselage.<br />

Covering and finish<br />

The model is covered and painted from<br />

the factory. However where you remove material<br />

from the dummy engine, you have to cover<br />

the areas with fuel proof paint.<br />

The original aeroplane was covered with linen<br />

fabric and coated several times with dope. This<br />

gave a translucent, very glossy finish.<br />

The insignia (roundels on the wing upper<br />

and under sides) are painted with enamel. Same<br />

paint is used on the rudder.<br />

Balancing<br />

The center of gravity / balancing point should be<br />

approx. 4" = 10 cm from the leading edge of the<br />

wing, and make adjustments if necessary.<br />

Flying<br />

The photographs on the last page show<br />

flying with one model. Our model has been fitted<br />

The rigging wires<br />

Wing landing wires<br />

Wing warping wires<br />

Wing flying wires<br />

Wing warping wires<br />

Wing warping wires<br />

Morane Saulnier type L -ARF 8

with Super Tigre Blue Head .60 with more than<br />

enough power. It is advisable to fit an engine that<br />

does not protrude to far forward or some<br />

alterations have to be made in the fire wall.<br />

Let the engine swing a 14x4 propeller if<br />

possible. This gives better thrust outside the big<br />

cowl and reduces sound to a more realistic level.<br />

Flying characteristics are very forgiving<br />

but the aerobatic manoeuvers limited. Set the<br />

elevator at zero angle to the wing for the first<br />

flight but be prepared to give down elevator if the<br />

model climbs out too steep. This model should<br />

fly of the ground and not be pulled by the propeller.<br />

Ground handling, taxiing, on hard surface<br />

is difficult in anything but calm weather, because<br />

the model will weather-vane into the wind.<br />

Take-off should be done straight into the<br />

wind and the take-off run is relatively short. Make<br />

corrections with elevator and rudder. The wingwarping<br />

during take-off is slow and not so<br />

effective but in flight responsive enough. Turns<br />

should be executed using both wing-warping and<br />

rudder.<br />

Use gentle handling during approach and<br />

make the landing straight into the wind. On the<br />

ground, taxing, unless very calm weather,<br />

should only be attempted with assistance at the<br />

wing tips (as per prototype). Note that the gliding<br />

ratio with the engine throttled back, is very<br />

steep. Airplanes from this period usually had a<br />

very steep approach for landing.<br />

The model can be used for bomb<br />

dropping and there is ample weight allowance.<br />

The prototype had an over all weight of 3,9 kgs<br />

rendering a wing loading of approx. 17 oz/sq foot<br />

(52 g/dm²), which is a guaranty for slow and<br />

gentle flying.<br />

Happy landings!<br />

The Hotchkiss machinegun was installed<br />

on some aircraft with syncronisation shown<br />

earlier.<br />

Morane Saulnier type L -ARF 9

Servo installation<br />

The sketches below show a typical servo installation.<br />

The pushrods from the servos connect to the joy stick<br />

and the rudder bar with a kwick-link as shown or, with<br />

a ball link which gives a somewhat smother actuation.<br />

Wingwarping set up and wing warping servo installation<br />

Note that the servos are inverted in the tray and that<br />

the pushrods come out under the servo tray. The position<br />

of the tank, receiver and accu are optional and to<br />

the builders discression. The radio switch is<br />

conveniently mounted on the instrument panel<br />

Number 1 servo is the elevator servo, to be connected<br />

with the joy-stick.<br />

Number 2 servo is the rudder servo, to be<br />

connected with the rudder bar.<br />

Number 3 servo is the trhrottle servo to be<br />

connected forward through the firewall<br />

with the carburator/throttle arm.<br />

The wing warping servo is installed in the vertical tray<br />

above the lower pylon. Wires are connected from the<br />

servo arm to the arm of the actuator with the 2 pulleys.<br />

Neutral servo should render horisontal actuator arm.<br />

Wires to the<br />

servo arm<br />

Wing warping wires<br />

Wing warping wires<br />

Actuator arm<br />

The lower wing warping wires are looped half a turn<br />

around the pulley befor being led to the attachment<br />

points in the wing under side. There are two sets of<br />

wires which both are treated the same way. When<br />

there are 2 pulleys, the forward pulley is used for the<br />

shorter wire pair.<br />

Wing warping<br />

lower pulley

Landing gear suspension, bunge rubber installation<br />

The rubberband is laced as illustrated so that<br />

the wheel shaft is tight against the lower part of the<br />

shaft support. The more you stretch the rubber the<br />

harder the spring action will be.<br />

Tail skid bunge rubber installation<br />

The rubberband is attached at the 2 screws as<br />

illustrated. The more you stretch the rubber the harder<br />

the spring action will be.<br />

Rigging of upper pylon and lower wingwarping<br />

wires<br />

The upper landing wires are attached to the pylon in<br />

the sequence illustrated (1-6). Start with the outer<br />

wires and make sure that the wing is parrallel and<br />

perpendicular to the pylon.<br />

The upper wing warping wires are through the pulley<br />

in the upper pylon as illustrated. Start with the outer<br />

wires and make sure that the wing is given approx. 1<br />

inch washout (dihedral at the trailing edge) at the<br />

wingtips. Make sure that the wires run freely in the<br />

pulley.<br />

1.Outer left landing wire<br />

2.Outer right<br />

landing wire<br />

4.Center right<br />

landing wire<br />

3.Center left landing wire<br />

6.Inner right landing wire<br />

5.Inner left landing wire<br />

Outer left wing<br />

warping wire<br />

Inner left wing<br />

warping wire<br />

Outer right wing<br />

warping wire<br />

Inner right<br />

wing warping wire

What is in the box:<br />

The ARF kit contains the parts shown in the<br />

picture. All the rigging wires are supplied in<br />

the correct lengths and need only to be clipped<br />

to their positions.<br />

8<br />

1<br />

5<br />

4<br />

9<br />

7<br />

2<br />

6<br />

3<br />

10<br />

1. Fuselage with wing cabane and wingwarping<br />

pylons<br />

2. Landing gear<br />

3. Scale wheels<br />

4. Engine cowl<br />

5. Dummy engine with mount<br />

6. Scale propeller<br />

7. Tail skid assy.<br />

11<br />

8. Rudder<br />

9. Elevator<br />

10. Left wing panel<br />

11. Right wing panel<br />

12. Wires, turnbuckles and hardware for<br />

assembly (not shown)<br />

13. Assembly manual with scale<br />

documentation (not shown)<br />

K&W<br />

Model<br />

Airplanes Inc.<br />

P.O.Box 1229, Cebu City Centrl. Postoffice<br />

Cebu City 6000, Philippines<br />

Visiting address:<br />

3343 Gun-Ob, Kinalumsan,<br />

Lapu-Lapu City 6015, PHILIPPINES<br />

Phone +63 32-340 7147, Cellular +63 917-3200 985<br />

Telefax +63 32-340 7131, E-mail: kwmairpl@gsilink.com