Wellness & Nourishment ⢠GMP ⢠Advanced ... - Mælkeritidende

Wellness & Nourishment ⢠GMP ⢠Advanced ... - Mælkeritidende

Wellness & Nourishment ⢠GMP ⢠Advanced ... - Mælkeritidende

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

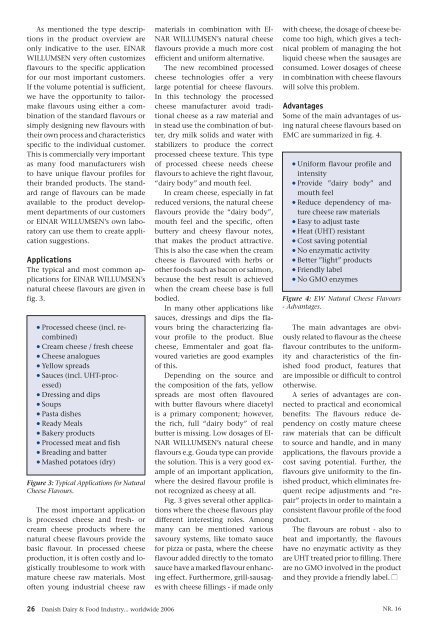

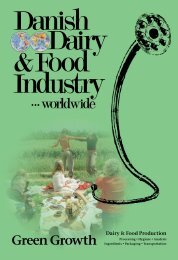

As mentioned the type descriptionsin the product overview areonly indicative to the user. EINARWILLUMSEN very often customizesflavours to the specific applicationfor our most important customers.If the volume potential is sufficient,we have the opportunity to tailormakeflavours using either a combinationof the standard flavours orsimply designing new flavours withtheir own process and characteristicsspecific to the individual customer.This is commercially very importantas many food manufacturers wishto have unique flavour profiles fortheir branded products. The standardrange of flavours can be madeavailable to the product developmentdepartments of our customersor EINAR WILLUMSEN’s own laboratorycan use them to create applicationsuggestions.ApplicationsThe typical and most common applicationsfor EINAR WILLUMSEN’snatural cheese flavours are given infig. 3.● Processed cheese (incl. recombined)● Cream cheese / fresh cheese● Cheese analogues● Yellow spreads● Sauces (incl. UHT-processed)● Dressing and dips● Soups● Pasta dishes● Ready Meals● Bakery products● Processed meat and fish● Breading and batter● Mashed potatoes (dry)Figure 3: Typical Applications for NaturalCheese Flavours.The most important applicationis processed cheese and fresh- orcream cheese products where thenatural cheese flavours provide thebasic flavour. In processed cheeseproduction, it is often costly and logisticallytroublesome to work withmature cheese raw materials. Mostoften young industrial cheese rawmaterials in combination with EI-NAR WILLUMSEN’s natural cheeseflavours provide a much more costefficient and uniform alternative.The new recombined processedcheese technologies offer a verylarge potential for cheese flavours.In this technology the processedcheese manufacturer avoid traditionalcheese as a raw material andin stead use the combination of butter,dry milk solids and water withstabilizers to produce the correctprocessed cheese texture. This typeof processed cheese needs cheeseflavours to achieve the right flavour,“dairy body” and mouth feel.In cream cheese, especially in fatreduced versions, the natural cheeseflavours provide the “dairy body”,mouth feel and the specific, oftenbuttery and cheesy flavour notes,that makes the product attractive.This is also the case when the creamcheese is flavoured with herbs orother foods such as bacon or salmon,because the best result is achievedwhen the cream cheese base is fullbodied.In many other applications likesauces, dressings and dips the flavoursbring the characterizing flavourprofile to the product. Bluecheese, Emmentaler and goat flavouredvarieties are good examplesof this.Depending on the source andthe composition of the fats, yellowspreads are most often flavouredwith butter flavours where diacetylis a primary component; however,the rich, full “dairy body” of realbutter is missing. Low dosages of EI-NAR WILLUMSEN’s natural cheeseflavours e.g. Gouda type can providethe solution. This is a very good exampleof an important application,where the desired flavour profile isnot recognized as cheesy at all.Fig. 3 gives several other applicationswhere the cheese flavours playdifferent interesting roles. Amongmany can be mentioned varioussavoury systems, like tomato saucefor pizza or pasta, where the cheeseflavour added directly to the tomatosauce have a marked flavour enhancingeffect. Furthermore, grill-sausageswith cheese fillings - if made onlywith cheese, the dosage of cheese becometoo high, which gives a technicalproblem of managing the hotliquid cheese when the sausages areconsumed. Lower dosages of cheesein combination with cheese flavourswill solve this problem.AdvantagesSome of the main advantages of usingnatural cheese flavours based onEMC are summarized in fig. 4.● Uniform flavour profile andintensity● Provide ”dairy body” andmouth feel● Reduce dependency of maturecheese raw materials● Easy to adjust taste● Heat (UHT) resistant● Cost saving potential● No enzymatic activity● Better ”light” products● Friendly label● No GMO enzymesFigure 4: EW Natural Cheese Flavours- Advantages.The main advantages are obviouslyrelated to flavour as the cheeseflavour contributes to the uniformityand characteristics of the finishedfood product, features thatare impossible or difficult to controlotherwise.A series of advantages are connectedto practical and economicalbenefits: The flavours reduce dependencyon costly mature cheeseraw materials that can be difficultto source and handle, and in manyapplications, the flavours provide acost saving potential. Further, theflavours give uniformity to the finishedproduct, which eliminates frequentrecipe adjustments and “repair”projects in order to maintain aconsistent flavour profile of the foodproduct.The flavours are robust - also toheat and importantly, the flavourshave no enzymatic activity as theyare UHT treated prior to filling. Thereare no GMO involved in the productand they provide a friendly label. ■26 Danish Dairy & Food Industry... worldwide 2006 NR. 16