Wellness & Nourishment ⢠GMP ⢠Advanced ... - Mælkeritidende

Wellness & Nourishment ⢠GMP ⢠Advanced ... - Mælkeritidende

Wellness & Nourishment ⢠GMP ⢠Advanced ... - Mælkeritidende

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

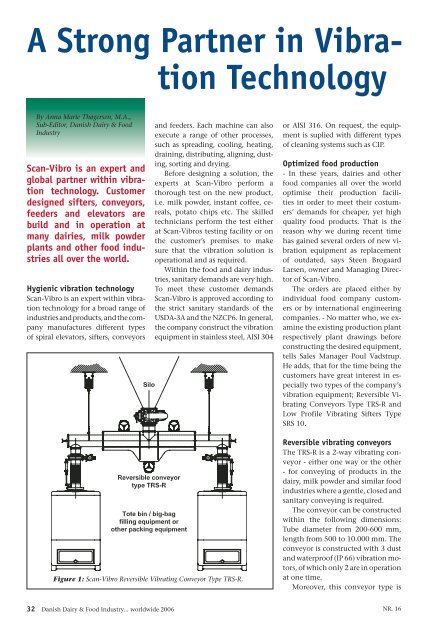

A Strong Partner in VibrationTechnologyBy Anna Marie Thøgersen, M.A.,Sub-Editor, Danish Dairy & FoodIndustryScan-Vibro is an expert andglobal partner within vibrationtechnology. Customerdesigned sifters, conveyors,feeders and elevators arebuild and in operation atmany dairies, milk powderplants and other food industriesall over the world.Hygienic vibration technologyScan-Vibro is an expert within vibrationtechnology for a broad range ofindustries and products, and the companymanufactures different typesof spiral elevators, sifters, conveyorsand feeders. Each machine can alsoexecute a range of other processes,such as spreading, cooling, heating,draining, distributing, aligning, dusting,sorting and drying.Before designing a solution, theexperts at Scan-Vibro perform athorough test on the new product,i.e. milk powder, instant coffee, cereals,potato chips etc. The skilledtechnicians perform the test eitherat Scan-Vibros testing facility or onthe customer’s premises to makesure that the vibration solution isoperational and as required.Within the food and dairy industries,sanitary demands are very high.To meet these customer demandsScan-Vibro is approved according tothe strict sanitary standards of theUSDA-3A and the NZCP6. In general,the company construct the vibrationequipment in stainless steel, AISI 304or AISI 316. On request, the equipmentis suplied with different typesof cleaning systems such as CIP.Optimized food production- In these years, dairies and otherfood companies all over the worldoptimise their production facilitiesin order to meet their costumers’demands for cheaper, yet highquality food products. That is thereason why we during recent timehas gained several orders of new vibrationequipment as replacementof outdated, says Steen BrogaardLarsen, owner and Managing Directorof Scan-Vibro.The orders are placed either byindividual food company customersor by international engineeringcompanies. - No matter who, we examinethe existing production plantrespectively plant drawings beforeconstructing the desired equipment,tells Sales Manager Poul Vadstrup.He adds, that for the time being thecustomers have great interest in especiallytwo types of the company’svibration equipment; Reversible VibratingConveyors Type TRS-R andLow Profile Vibrating Sifters TypeSRS 10.Figure 1: Scan-Vibro Reversible Vibrating Conveyor Type TRS-R.Reversible vibrating conveyorsThe TRS-R is a 2-way vibrating conveyor- either one way or the other- for conveying of products in thedairy, milk powder and similar foodindustries where a gentle, closed andsanitary conveying is required.The conveyor can be constructedwithin the following dimensions:Tube diameter from 200-600 mm,length from 500 to 10.000 mm. Theconveyor is constructed with 3 dustand waterproof (IP 66) vibration motors,of which only 2 are in operationat one time.Moreover, this conveyor type is32 Danish Dairy & Food Industry... worldwide 2006 NR. 16