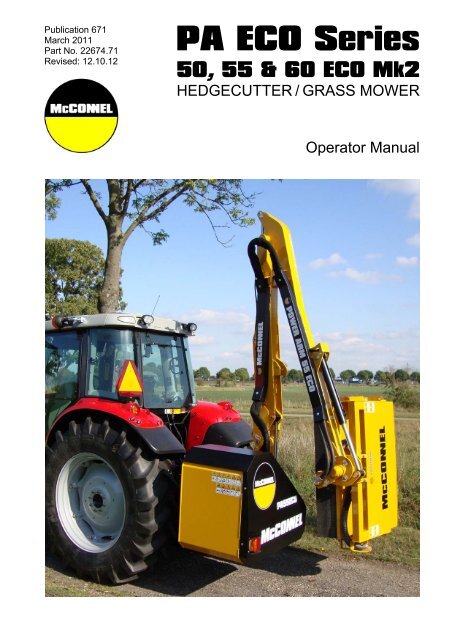

PA50, 55 & 60 ECO MK2 - Operator Manual - McConnel

PA50, 55 & 60 ECO MK2 - Operator Manual - McConnel

PA50, 55 & 60 ECO MK2 - Operator Manual - McConnel

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2. REMEDIES AND PROCEDURES2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the <strong>McConnel</strong>web site and confirms the registration to the purchaser by completing the confirmation form inthe operator’s manual.2.02. Any fault must be reported to an authorised <strong>McConnel</strong> dealer as soon as it o ccurs. Continueduse of a m achine, after a f ault has occurred, can result in further component failure for which<strong>McConnel</strong> Ltd cannot be held liable.2.03. Repairs should be undertaken within two days of the failure. Claims submitted for re pairsundertaken more than 2 weeks after a failure ha s occurred, or 2 days after the pa rts weresupplied will be rejected, unless the delay has been authorised by <strong>McConnel</strong> Ltd.2.04. All claims must be submitted, by an aut horised <strong>McConnel</strong> Service Dealer, within 30 days of thedate of repair.2.05. Following examination of the claim an d parts the manufacture will pay, at their discretio n, forany valid claim the cost of any parts and an appropriate labour allowance if applicable.2.06. The submission of a claim is not a guarantee of payment.2.07. Any decision reached by <strong>McConnel</strong> Ltd. is final.3. LIMITATION OF LIABILITY3.01. The manufacturer disclaims any express (exc ept as set forth herein) an d implied warrantieswith respect to the goods including, but not limited to, merchantability and fitness for a particularpurpose.3.02. The manufacturer makes no warranty as to the design, capability, capacity or suitability for useof the goods.3.03. Except as provi ded herein, the m anufacturer shall have no liability or responsibility to thepurchaser or any other person or entity with respect to any liability, loss, or damage caused o ralleged to be caused directly or indirectly by the goods including, but not limited to, any indirect,special, consequential, or incidental damages resulting from the use or operation of the goodsor any breach of this warranty. Notwithstanding the above limitations and warranties, themanufacturer’s liability hereund er for d amages incurred by the purchase r or others shall notexceed the price of the goods.3.04. No action arising out of any claimed breach of this warranty or transactions under this warrantymay be brought more than one (1) year after the cause of the action has occurred.4. MISCELLANEOUS4.01. The manufacturer may waive compliance with any of the terms of this limited warranty, but nowaiver of any terms shall be deemed to be a waiver of any other term.4.02. If any provision of this limited warranty shall violate any applic able law and is held to beunenforceable, then the invalidity of such provis ion shall not invalidate any other provisionsherein.4.03. Applicable law may provide rights an d benefits to the purchaser in addition to those providedherein.

DECLARATION OF CONFORMITYConforming to EU Machinery Directive 2006/42/ECWe,McCONNEL LIMITED, Temeside Works, Ludlow, Shropshire SY8 1JL, UKHereby declare that:The Product; Tractor Mounted Hedgecutter / Grass MowerProduct Code; PE50, PE<strong>55</strong>, PE<strong>60</strong>Serial No. & Date ………………………………… Type …………………………Manufactured in; United KingdomComplies with the required provisions of the Machinery Directive 2006/42/ECThe machinery directive is supported by the following harmonized standards; BS EN ISO 14121-1 (2007) Safety of machinery - Risk assessment, Part 1:Principles Part 2: practical guide and examples of methods. BS EN ISO 12100-1 (2010) Safety of mach inery - Part 1: Basic terminology andmethodology Part 2: Technical principles. BS EN 349(1993)+ A1 (2008) Safety of machinery - Minimum distances to avoid theentrapment with human body parts. BS EN 953 (1998) Safety of machinery - Guards General requirements for thedesign and construction of fixed and movable guards. BS EN 982(1996)+ A1 (2008) Safety requirements for fluid power systems and theircomponents. HydraulicsMcCONNEL LIMITED operates an IS O 9001:2008 quality management system,certificate number: FM25970.This system is continually assessed by the;British Standards Institution (BSI), Beech House, Milton Keynes, MK14 6ES, UKBSI is accredited by UK Accreditation Service, accreditation number: UKAS 003.The EC declaration only applies if the machine stated above is used inaccordance with the operating instructions.Signed …………………................ Responsible Personon behalf of McCONNEL LIMITEDStatus: General Manager Date: May 2011

POWER ARM INSPECTION AND MAINTENANCEA daily equipment inspection of the trac tor and mower should be conduct ed before theequipment is used. You may use the ins pection sheets to assist with these dailyinspections. Any damaged or missing guar ds should be repaired or replaced befor eoperating the mower. Failure t o repair the damaged shield c an result in objects beingthrown from the mower and possibly hitting the operator or bystander.Inspect the Mower for Safe Operating ConditionMake sure the driveline guards and shielding are in place and in good repair.Inspect the flexible thrown object shieldi ng to assure that they are in plac e on thefront and rear of the mower head and in good repair. Rep air or replace anydamaged or missing thrown object shields.Ensure the mower cutting height is se t high enough to reduce the possibility of themower blades contacting the ground. Actual height will be dependent on the groundconditions. Increase the height when working in rough or undulating conditions. Inspect for broken, chipped, bent, missi ng, or severely worn blades. Replacedamaged blades before operating the mower. Ensure the blade retaining bolts andfasteners are secure and tight. Ensure all head bolts and nuts are tight. Lubricate the driveline universal joints and telescoping members daily. Grease the rotor and roller bearings and inspect their condition. Inspect for any oil leaks or damaged hoses Inspect for worn or damaged decals and s afety instructions. Replace unreadable,damaged or missing safety decals. Follow the operator’s manual(s) inspec tion and maintenanc e instructions forlubricating parts, and keeping thrown obj ect shielding, driveline guards, rotatingparts shields, mower blades and decals in good repair.Inspect the Tractor for Safe Operating Condition: Inspect the controls, lights, SMVs (Slo w Moving Vehicle sign), seat bel ts, andROPS to assure that they are in place and in good working order. Be sure the tires, wheels, lug bolts/nuts are in good condition. Make sure the tractor brakes and steering are in proper operating condition. Follow the operator’s manual(s) ins pection and m aintenance procedures forkeeping the tractor in good and safe condition before operating.The inspection sheet on the foll owing page should be kept in this book a s a record. Asecond sheet is included for you to cut out and photocopy or the inspection sheets can bedownloaded from our website at;http://www.mcconnel.com/support/aftersales/default.aspx?nav=After Sales

POWER ARM PRE-OPERATION InspectionPower Arm ID ________________ Date: _______________ Shift: _______________WARNINGBefore conducting the inspection, make sure the tractor engine is off, the key removed, allrotation has stopped and the tractor is in park with the parking brake engaged. Make surethe mower head is resting on the ground or is securely blocked up and supported and allhydraulic pressure has been relieved.ItemThe <strong>Operator</strong>’s <strong>Manual</strong> is in the Canister on the mowerAll Warning Decals are in place, clean and legibleAll Lights are clean and workingThe Mounting frame bolts are in place and tightThe Arm pivot pins are tight and correctly securedThere are no cracks in the armsThe Hyd. Cylinder pins are tight and correctly securedThe Hyd Cylinder hose connections are tightThe Hyd. Pump hose connections are tightThe Hyd. Valve hose connections are tightThe Hyd. Valve controls function properlyThere are no damaged hosesThe Oil level is to the green mark on the tank sight glassThere is no evidence of Hydraulic oil leaksFlails are not missing, chipped, broken or excessively wornThe Flail bolts are tightThe Front & Rear Flaps are fittrd and in good conditionThe Front hood is in place and in good conditionThe Wire Trap is in good conditionThe Skid shoes are in good condition & tightThere are no cracks or holes in flail casingThe Hyd. motor mounting bolts are tightAll Flail Head Nuts and Bolts are tightThe Rotor Bearings are in good condition and greasedThe Roller bearings are in good condition and greasedThe drive line Shaft guard is in good conditionThe drive line shaft guard is correctly securedControls are securely mounted in the cabWith engine running check arm operationHave a spare pack of flails, bushes, bolts and nutsCondition atstart of shiftSpecific Comments if not O.K.<strong>Operator</strong>s Signature: ___________________________________________DO NOT OPERATE an UNSAFE TRACTOR or MOWER

TRACTOR PRE-OPERATION InspectionPower Arm ID ________________ Date: _______________ Shift: _______________WARNING Before conducting the inspection, make sure the tractor engine is off, the key is removedall rotation has stopped and the tractor is in park with the parking brake engaged. Anyimplement attached to the tractor is firmly on the ground.ItemThe flashing lights function properly.All lights are clean and working correctlyAll cab windows are clean and wipers working correctlyThe SMV sign, where required, is clean and visible.The tyres are in good condition with correct pressure.The wheel nuts are tight.The tractor brakes are in good condition.The steering linkage is in good condition.There are no visible oil leaks.The hydraulic controls function properly.The ROPS or ROPS cab is in good condition.The seatbelt is in place and in good condition.The 3-point hitch is in good condition.The drawbar/pick up hook is secure & in good conditionThe PTO master shield is in place.The engine oil level is full.The brake fluid level is full.The power steering fluid level is full.The fuel level is adequate.The engine coolant fluid level is full.The radiator & oil cooler are free of debris.The air filter is in good conditionCondition atstart of shiftSpecific Comments if not O.K.<strong>Operator</strong>s Signature: ___________________________________________DO NOT OPERATE an UNSAFE TRACTOR or MOWER

POWER ARM PRE-OPERATION InspectionPower Arm ID ________________ Date: _______________ Shift: _______________WARNINGBefore conducting the inspection, make sure the tractor engine is off, the key removed, allrotation has stopped and the tractor is in park with the parking brake engaged. Make surethe mower head is resting on the ground or is securely blocked up and supported and allhydraulic pressure has been relieved.ItemThe <strong>Operator</strong>’s <strong>Manual</strong> is in the Canister on the mowerAll Warning Decals are in place, clean and legibleAll Lights are clean and workingThe Mounting frame bolts are in place and tightThe Arm pivot pins are tight and correctly securedThere are no cracks in the armsThe Hyd. Cylinder pins are tight and correctly securedThe Hyd Cylinder hose connections are tightThe Hyd. Pump hose connections are tightThe Hyd. Valve hose connections are tightThe Hyd. Valve controls function properlyThere are no damaged hosesThe Oil level is to the green mark on the tank sight glassThere is no evidence of Hydraulic oil leaksFlails are not missing, chipped, broken or excessively wornThe Flail bolts are tightThe Front & Rear Flaps are fittrd and in good conditionThe Front hood is in place and in good conditionThe Wire Trap is in good conditionThe Skid shoes are in good condition & tightThere are no cracks or holes in flail casingThe Hyd. motor mounting bolts are tightAll Flail Head Nuts and Bolts are tightThe Rotor Bearings are in good condition and greasedThe Roller bearings are in good condition and greasedThe drive line Shaft guard is in good conditionThe drive line shaft guard is correctly securedControls are securely mounted in the cabWith engine running check arm operationHave a spare pack of flails, bushes, bolts and nutsCondition atstart of shiftSpecific Comments if not O.K.<strong>Operator</strong>s Signature: ___________________________________________DO NOT OPERATE an UNSAFE TRACTOR or MOWER

TRACTOR PRE-OPERATION InspectionPower Arm ID ________________ Date: _______________ Shift: _______________WARNING Before conducting the inspection, make sure the tractor engine is off, the key is removedall rotation has stopped and the tractor is in park with the parking brake engaged. Anyimplement attached to the tractor is firmly on the ground.ItemThe flashing lights function properly.All lights are clean and working correctlyAll cab windows are clean and wipers working correctlyThe SMV sign, where required, is clean and visible.The tyres are in good condition with correct pressure.The wheel nuts are tight.The tractor brakes are in good condition.The steering linkage is in good condition.There are no visible oil leaks.The hydraulic controls function properly.The ROPS or ROPS cab is in good condition.The seatbelt is in place and in good condition.The 3-point hitch is in good condition.The drawbar/pick up hook is secure & in good conditionThe PTO master shield is in place.The engine oil level is full.The brake fluid level is full.The power steering fluid level is full.The fuel level is adequate.The engine coolant fluid level is full.The radiator & oil cooler are free of debris.The air filter is in good conditionCondition atstart of shiftSpecific Comments if not O.K.<strong>Operator</strong>s Signature: ___________________________________________DO NOT OPERATE an UNSAFE TRACTOR or MOWER

CONTENTSGeneral Information 1Features 2Safety Information 4Fitting (Tractor Requirements) 8Tractor Preparation 9Delivery & Pre-Attachment 10Hydraulic Oil 11Attachment to Tractor 12PTO Driveshaft Installation 16Fitting <strong>Operator</strong> Controls 17Flailhead Attachment 18Running Up Procedure 19Emergency Stopping 19Pre-Work Preparation & Precautions 20Removal From Tractor 21Storage 21Operation 22Cable Controls 23Cable Rotor Control 26Electric Switchbox Controls 27Electric Monolever Controls 31XTC Proportional Controls 35V4 Proportional Controls 39Slew & Lift Locks 52Breakaway 53Powered Slew 54Moving Into Transport Position <strong>55</strong>Transporting The Machine 57Moving From Transport To Work 57Operating Speeds 58Hazards & Dangers 59Overhead Power Lines <strong>60</strong>Hedgecutting Procedure 62Lift Float (Option) 63Angle Float 64Maintenance 65

For Safety and Performance …ALWAYS READ THIS BOOK FIRSTMcCONNEL LIMITEDTemeside WorksLudlowShropshireEnglandTelephone: 01584 873131www.mcconnel.comNOISE STATEMENTThe equivalent daily personal noise exposure from this machine measured at the operators’ ear iswithin the range 78 – 85 dB, these figures apply to a normal distribution of use where the noisefluctuates between zero and maximum. The figures assume that the machine is fitted to a tractorwith a ‘quiet’ cab with the windows closed in a generally open environment. We recommend thatthe windows are kept closed. With the cab rear window open the equivalent daily personal noiseexposure will increase to a figure within the range 82 – 88 dB. At equivalent daily noise exposurelevels of between 85 – 90 dB ear protection is recommended – it should be used if any window isleft open.

GENERAL INFORMATIONRead this manual before fitting or operating the machine. Whenever any doubt existscontact your dealer or the <strong>McConnel</strong> Service Department for assistance.Use only <strong>McConnel</strong> Genuine Parts on <strong>McConnel</strong> equipment and machines.DEFINITIONS - The following definitions apply throughout this manual:WARNING:An operating procedure, technique etc., which can result in personal injury or loss of life ifnot observed carefully.CAUTION:An operating procedure, technique etc., which can result in the damage of either machineor equipment if not observed carefully.NOTE:An operating procedure, technique etc., which is considered essential to emphasise.LEFT AND RIGHT HAND:This term is applicable to the machine when fitted to the tractor and viewed from the rear.This also applies to tractor references.Note: The illustrations in this manual are for instructional purposes only and may on occasion notshow some components in their entirety. In some instances an illustration may appear slightlydifferent to that of your particular model but the general procedure will be the same. E&OA.MACHINE & DEALER INFORMATIONRecord the Serial Number of your machine on this page and always quote this number whenordering parts. Whenever information concerning the machine is requested remember also tostate the make and model of tractor to which the machine is fitted.Machine Serial Number:Machine Model details:Dealer Name:Dealer Address:Dealer Telephone No:Dealer Email Address:Installation Date:1

FEATURES<strong>PA50</strong> Eco Models Linkage mounted. 5.0m reach Right hand cutting. <strong>Operator</strong> guard. Hydraulic safety breakaway. 95° powered slew. 200 litre hydraulic reservoir. Storage support legs. Choice of Flailheads. Choice of Controls.PA<strong>55</strong> Eco Models Linkage mounted. 5.5m reach Right hand cutting. <strong>Operator</strong> guard. Hydraulic safety breakaway. 95° powered slew. 200 litre hydraulic reservoir. Storage support legs. Choice of Flailheads. Choice of Controls.PA<strong>60</strong> Eco Models Linkage mounted. 6.0m reach Right hand cutting. <strong>Operator</strong> guard. Hydraulic safety breakaway. 95° powered slew. 200 litre hydraulic reservoir. Storage support legs. Choice of Flailheads. Choice of Controls.Options Lift Float Kit2

SAFETY SECTIONThis machine has the potential to be extremely dangerous, in the wrong hands it can kill ormaim. It is therefore imperative that both owner, and operator of this machine, read andunderstand the following section to ensure that they are fully aware of the dangers that do,or may exist, and their responsibilities surrounding the use and operation of the machine.The operator of this machine is responsible not only for their own safety but equally for thesafety of others who may come into the close proximity of the machine, as the owner youare responsible for both.When the machine is not in use the cutting head should be lowered to rest on the ground.In the event of a fault being detected with the machine’s operation it should be stoppedimmediately and not used again until the fault has been corrected by a qualified technician.POTENTIAL SIGNIFICANT DANGERS ASSOCIATED WITH THE USE OF THISMACHINE:▲ Being hit by debris thrown by rotating components.▲ Being hit by machine parts ejected through damage during use.▲ Being caught on a rotating power take-off (PTO) shaft.▲ Being caught in other moving parts i.e.: belts, pulleys and cutting heads.▲ Electrocution from Overhead Power Lines (by contact with or ‘flashover’ from).▲ Being hit by cutting heads or machine arms as they move.▲ Becoming trapped between tractor and machine when hitching or unhitching.▲ Tractor overbalancing when machine arm is extended.▲ Injection of high-pressure oil from hydraulic hoses or couplings.▲ Machine overbalancing when freestanding (out of use).▲ Road traffic accidents due to collision or debris on the road.4

BEFORE USING THIS MACHINE YOU MUST:▲ Ensure you read all sections of the operator handbook.▲ Ensure the operator is, or has been, properly trained to use the machine.▲ Ensure the operator has been issued with and reads the operator handbook.▲ Ensure the operator understands and follows the instructions in operator handbook.▲ Ensure the tractor front, rear and side(s) are fitted with metal mesh or polycarbonateguards of suitable size and strength to protect the operator against thrown debris orparts.▲ Ensure tractor guards are fitted correctly, are undamaged and kept properlymaintained.▲ Ensure that all machine guards are in position, are undamaged, and are keptmaintained in accordance with the manufacturer’s recommendations.▲ Ensure flails and their fixings are of a type recommended by the manufacturer, aresecurely attached and that none are missing or damaged.▲ Ensure hydraulic pipes are carefully and correctly routed to avoid damage by chaffing,stretching or pinching and that they are held in place with the correct fittings.▲ Always follow the manufacturer’s instructions for attachment and removal of themachine from the tractor.▲ Check that the machine fittings and couplings are in good condition.▲ Ensure the tractor meets the minimum weight recommendations of the machine’smanufacturer and that ballast is used as necessary.▲ Always inspect the work area thoroughly before starting to note obstacles and removewire, bottles, cans and other debris.▲ Use clear suitably sized warning signs to alert others to the nature of the machineworking within that area. Signs should be placed at both ends of the work site. (It isrecommended that signs used are of a size and type specified by the Department ofTransport and positioned in accordance with their, and the Local Highways Authority,guidelines).▲ Ensure the operator is protected from noise. Ear defenders should be worn and tractorcab doors and windows must be kept closed. Machine controls should be routedthrough proprietary openings in the cab to enable all windows to be shut fully.▲ Always work at a safe speed taking account of the conditions i.e.: terrain, highwayproximity and obstacles around and above the machine. Extra special attention shouldbe applied to Overhead Power Lines. Some of our machines are capable of reach inexcess of 8 metres (26 feet) this means they have the potential to well exceed, bypossibly 3 metres (9’ 9”), the lowest legal minimum height of 5.2 metres from theground for 11,000 and 33,000 volt power lines. It cannot be stressed enough thedangers that surround this capability, it is therefore vital that the operator is fully awareof the maximum height and reach of the machine, and that they are fully conversantwith all aspects regarding the safe minimum distances that apply when working withmachines in close proximity to Power Lines. (Further information on this subject can beobtained from the Health & Safety Executive or your Local Power Company).5

▲ Always disengage the machine, kill the tractor engine, remove and pocket the keybefore dismounting for any reason.▲ Always clear up all debris left at the work area, it may cause hazard to others.▲ Always ensure when you remove your machine from the tractor that it is left in a safeand stable position using the stands and props provided and secured if necessary.WHEN NOT TO USE THIS MACHINE:▲ Never attempt to use this machine if you have not been trained to do so.▲ Never use a machine until you have read and understood the operator handbook, arefamiliar with it, and practiced the controls.▲ Never use a machine that is poorly maintained.▲ Never use a machine if guards are missing or damaged.▲ Never use a machine on which the hydraulic system shows signs of wear or damage.▲ Never fit, or use, a machine on a tractor that does not meet the manufacturer’sminimum specification level.▲ Never use a machine fitted to a tractor that does not have suitable front, rear andside(s) cab guarding made of metal mesh or polycarbonate.▲ Never use the machine if the tractor cab guarding is damaged, deteriorating or badlyfitted.▲ Never turn a machine cutting head to an angle that causes debris to be ejectedtowards the cab.▲ Never start or continue to work a machine if people are nearby or approaching - Stopand wait until they are at a safe distance before continuing. WARNING: Some CuttingHeads may continue to ‘freewheel’ for up to 40 seconds after being stopped.▲ Never attempt to use a machine on materials in excess of its capability.▲ Never use a machine to perform a task it has not been designed to do.▲ Never operate the tractor or machine controls from any position other than from thedriving seat, especially whilst hitching or unhitching the machine.▲ Never carry out maintenance of a machine or a tractor whilst the engine is running –the engine should be switched off, the key removed and pocketed.▲ Never leave a machine unattended in a raised position – it should be lowered to theground in a safe position on a level firm site.▲ Never leave a tractor with the key in or the engine running.▲ Never carry out maintenance on any part or component of a machine that is raisedunless that part or component has been properly substantially braced or supported.▲ Never attempt to detect a hydraulic leak with your hand – use a piece of cardboard.▲ Never allow children near to, or play on, a tractor or machine under any circumstances.6

ADDITIONAL SAFETY ADVICETraining<strong>Operator</strong>s need to be competent and fully capable of operating this machine in a safe andefficient way prior to attempting to use it in any public place. We advise therefore that theprospective operator make use of relevant training courses available such as those run byAgricultural Training Boards, Agricultural Colleges and Dealers.Working in Public PlacesWhen working in public places such as roadsides, consideration should be paid to othersin the vicinity. Stop the machine immediately when pedestrians, cyclists and horse ridersetc. pass. Restart only when they are at a distance that causes no risk to their safety.Warning SignsIt is advisable that any working area be covered by suitable warning signs and statutory inpublic places. Signs should be highly visible and well placed in order to give clearadvanced warning of the hazard. Contact the Department of Transport or your LocalHighways Authority to obtain detailed information on this subject. The latter should becontacted prior to working on the public highway advising them of the time and location ofthe intended work asking what is required by way of signs and procedure. – ‘Nonauthorisedplacement of road signs may create offences under the Highways Act’.Use of Warning Signs▲ On two-way roads one set of signs is needed facing traffic in each direction.▲ Work should be within 1 mile of the signs.▲ Work only when visibility is good and at times of low risk e.g.: NOT during ‘rush-hour’.▲ Vehicles should have an amber-flashing beacon.▲ Ideally, vehicles should be conspicuously coloured.▲ Debris should be removed from the road and path as soon as practicable, and atregular intervals, wearing high visibility clothing and before removing the hazardwarning signs.▲ Collect all road signs promptly when the job is completed.Although the information given here covers a wide range of safety subjects, it is impossible topredict every eventuality that can occur under differing circumstances whilst operating thismachine. No advice given here can replace ‘good common sense’ and ‘total awareness’ at all times,but will go a long way towards the safe use of your <strong>McConnel</strong> machine.7

FITTING – Tractor requirementsMinimum Tractor Weight - including ballast weight if necessary:<strong>PA50</strong> <strong>ECO</strong> – 3500kg.PA<strong>55</strong> <strong>ECO</strong> – 3500kg.PA<strong>60</strong> <strong>ECO</strong> – 4000kg.Minimum HP RequirementsAll models – 65HPLinkageCategory 2PTO ShaftTractor must be equipped with a live drive PTO to enable forward motion to be stoppedwhile the flail head continues to operate.Check Chains/Stabilizers:Check chains or stabilizers must be fitted and tightened.8

TRACTOR PREPARATIONFitting Tractor Guard: Use tractor with safetyglass windows if possible and fit <strong>Operator</strong>guard (part no. 7313324) using the hooksprovided. Shape mesh to cover all vulnerableareas. Remember the driver must be lookingthrough mesh and/or polycarbonate glazingwhen viewing the flail head in any workingposition - unless the tractor/cab manufacturercan demonstrate that the penetration resistance is equivalent to, or higher than, thatprovided by mesh/polycarbonate glazing. If the tractor has a roll bar only, a frame must bemade to carry both mesh and polycarbonate glazing.Wheel Width: Set wheel widths as wide as possible.Lift Links: Adjust lift links until they are equal length.Tractor Ballast: It is imperative when attaching ‘third-party’ equipment to a tractor that themaximum possible stability of the machine and tractor combination is achieved – this canbe accomplished by the utilization of ‘ballast’ in order to counter-balance the additionalequipment added.Front weights may be required to place 15% of total outfit weight on the front axle forstable transport on the road and to reduce ‘crabbing’ due to the drag of the cutting unitwhen working on the ground.Rear weights may be required to maintain a reasonable amount of rear axle load on theopposite wheel from the arms when in work; for normal off-ground work i.e. hedge cuttingthis should be 20% of rear axle weight or more for adequate control, and for ground worki.e. verge mowing with experienced operators, this can be reduced to 10%.All factors must be addressed in order to match the type and nature of the equipmentadded to the circumstances under which it will be used – in the instance of Power ArmHedgecutters it must be remembered that the machines centre of gravity during work willbe constantly moving and will differ from that during transport mode, therefore balancebecomes critical.Factors that effect stability:• Centre of gravity of the tractor/machine combination.• Geometric conditions, e.g. position of the cutting head and ballast.• Weight, track width and wheelbase of the tractor.• Acceleration, braking, turning and the relative position of the cutting head during these• operations.• Ground conditions, e.g. slope, grip, load capability of the soil/surface.• Rigidity of implement mounting.Suggestions to increase stability:• Increasing rear wheel track; a tractor with a wider wheel track is more stable.• Ballasting the wheel; it is preferable to use external weights but liquid can be added toaround 75% of the tyre volume – water with anti-freeze or the heavier Calcium Chloridealternative can be used.• Addition of weights – care should be taken in selecting the location of the weights to• ensure they are added to a position that offers the greatest advantage.• Front axle locking; a ram can be used to ‘lock’ the front axle in work only – locking the axle• moves the ‘balance line’ and can be used to transfer weight to the front axle from the rear(check with tractor manufacturer).The advice above is offered as a guide for stability only and is not a guide to tractor strength - it istherefore recommended that you consult your tractor manufacturer or local dealer to obtain specificadvise on this subject, additionally advice should be sought from a tyre specialist with regard to tyrepressures and ratings suitable for the type and nature of the machine you intend to fit.9

DELIVERY & PRE-ATTACHMENT (Dealer Reference)DeliveryThe machine will be delivered in a partially dismantled condition secured with transportstraps and banding. Select a firm level site on which to place the machine before removingthe straps, banding and other loose items.Handling the MachineHandling of the machine should always be performed using suitable overhead liftingequipment with a minimum safe lifting capacity over and above the maximum weight of themachine. Always ensure the machine is balanced during the lifting procedure and that allbystanders are kept well clear of the raised machine.Post Delivery AssemblyTo allow for a compact shipping state the machine will be delivered with the tension linkdisconnected from the rocker and the stand legs retracted – these items will need to becorrectly installed before initial attachment to a tractor.The procedure is as follows:Stand LegsRaise the machine using suitableoverhead lifting equipment.Lower stand legs and secure inposition using pins and locking pins –the hole position selected should beat a height that places the gearboxstub axle approximately 75mm (3”)below the height of the tractor’s PTOshaft when the machine is at rest onthe ground. Note the hole positionused and ensure the equivalent oneis used on both sides of the machine10

HYDRAULIC OILHydraulic Oil ReservoirFill the tank with oil selected from the chartbelow or a good quality equivalent to a pointwhere the level is between the minimum andmaximum marks on the tank gauge. Whenthe machine is initially run the level will dropas the oil is drawn into the circuit - top backup as required to the correct level on thegauge.Always use clean receptacles when handlingand transferring oil to avoid moisture or dirtcontamination that can damage componentsand/or reduce machine performance.NOTE: Refer to the maintenance section for further information on the subject of hydraulicoil and system filtration.Reservoir CapacityThe oil tank capacity of the machine is approximately 200 Litres.Recommended Hydraulic OilsFor initial filling of the oil reservoir, periodic oil changes and replenishment purposes thefollowing hydraulic oils, or a good quality equivalent are recommended:NOTE: Only use oils that are ISO 18/13 or cleaner.Manufacturer Cold or Temperate Climate Hot ClimateBP Bartran 46Energol HLP-HM 46Bartran 68Energol HLP-HM 68CASTROL Hyspin AWH-M 46 Hyspin AWH-M 68COMMA Hydraulic Oil LIC 15 Hydraulic Oil LIC 20ELF Hydrelf HV 46Hydrelf HV 68Hydrelf XV 46ESSO Univis N 46 Univis N 68FUCHS(UK/Non UK markets*)Renolin 46Renolin HVZ 46Renolin CL46/B15*Renolin AF46/ZAF46B*Renolin 68Renolin HVZ 68Renolin CL68/B20*Renolin AF68/ZAF68B*GREENWAY Excelpower HY 68 Excelpower HY 68MILLERS Millmax 46Millmax HV 46MORRIS Liquimatic 5Liquimatic HV 46Triad 46SHELL Tellus 46Tellus T46TEXACO Rando HD 46Rando HDZ 46Millmax 68Millmax HV 68Liquimatic 6Liquimatic HV 68Triad 68Tellus 68Tellus T68Rando HD 68Rando HDZ 68TOTAL Equivis ZS 46 Equivis ZS 6811

ATTACHMENT TO TRACTORPosition the tractor squarely to the machineplacing the draft links at the same height asthe mainframe attachment points.Carefully reverse the tractor up to themachine until the draft links are positionedfor attachment – select the rear most holeon the machines lower link brackets thatallows the machine to be mounted withoutfouling the tractor.Attach the tractor draft links to the machineusing pins provided and secure in position -ensure the same mounting hole is selectedon each side of the machine.If necessary fit the spacers supplied tominimise sideways movement of the draftlinks within the hitch bracket12

Fit the stabilizer into position with its armsaligned with the holes of the main frameand attach the stabilizer nose to the tractorstop link – select the highest possibleposition available avoiding any loadsensing properties.NOTE: The bolt on nose of the stabiliser isreversible in order to accommodatevariations of tractor linkage designs.<strong>McConnel</strong> offer various versions ofstabilizer noses for differing types andmakes of tractors – contact your localdealer or <strong>McConnel</strong> Parts Department forfurther information.Secure the stabiliser in position using thefixings provided. Attach the stabiliser arm tothe machine selecting the lowest holepossible.Fit top link between the stabiliser and themainframes upper linkage point.13

Secure top link in position using fixingsprovided.Raise the machine on the tractors linkage toa height where the tractors PTO and thestub axle of the machines gearbox areapproximately in line with each other.Note: As lift occurs be aware the machinemay tilt slightly.WARNING!The quadrant lever or machine controlsmust only be operated from the tractorseat. Ensure no one is standing on,between, or near the linkage arms orbars during this procedure.Adjust the top link to bring the machineframe into the vertical position.14

Remove leg pins and raise the stand legs totheir stowage position – replace leg pinsand secure in place with ‘R’ clips.Adjust check chains to prevent sidewaysmovement of the tractor’s linkage.Measure the PTO shaft and cut to thedimension shown below. The finished lengthof the shaft should be 75mm (3”) less thanthe measured distance ‘A’ between tractorshaft and gearbox stub shaft to allow forfitting. Refer to PTO installation page.NOTE: For subsequent use with differenttractors, measure again - there must be aminimum shaft overlap of 150mm (6”).When the PTO shaft is in position attachtorque chains to convenient locations toprevent rotation of the shaft guarding.Fit the machine control unit in the tractor cab in a convenient location that allows for safeand easy operation of all the controls and functions.15

PTO DRIVESHAFT INSTALLATIONThe PTO driveshaft attaches between the tractor and the machine gearbox to transfer thepower required to the run and operate the machine – it is important to achieve the correctshaft length to avoid risk of it ‘bottoming out’ when raising or lowering the machine.The procedure for measuring andcutting the shaft is as follows:Measuring the PTO ShaftWith the machine attached to thetractor in the working position measurethe horizontal distance ‘A’ from thetractor’s PTO to the input shaft on themachines gearbox and subtract 75mm(3”) – this figure is the required shaftlength.Place the fully closed PTO shaft onthe ground and measure its overalllength, if the shaft is shorter than therequired length you can use it withoutthe need to shorten - providing itallows for a minimum 150mm (6”)overlap when fitted.If the shaft is longer subtract therequired shaft length plus an additional75mm (3”) - the resulting figure is theexcess length that will need to beremoved from each half of the shaft.Cutting the PTO ShaftSeparate the two halves and using themeasurement obtained above shortenboth the plastic guarding and the innersteel profile tubes of each shaft by thissame amount. De-burr the cut tubeswith a file to remove rough or sharpedges and thoroughly clean to removeswarf before greasing, assembling andfitting the shaft.NOTE: For subsequent use with different tractors the shaft should be measured again tocheck suitability – there must be a minimum shaft overlap of 150mm (6”).MaintenanceTo increase the working life of the PTO shaft it should be periodically checked, cleanedand lubricated – refer to the PTO maintenance section for further details on this subject.16

FITTING OPERATOR CONTROL UNITSFitment of the operator controls in the tractor cab will vary depending on the particularmodel or specification of machine – the information below lists the differing methods offitment for the various types of controls available.NOTE: Electric control units work within the range of 12v-16v DC and will require aminimum power supply of 12v DC.Cable ControlsCable control units are provided with, and attached to, a mounting bracket – the bracketshould be securely fixed to the internal mud wing or cab cladding in a suitable convenientlocation that offers ease of use without interfering with normal tractor operation.In deciding the final position of the control unit bear in mind the location of the cable run –make sure the minimum acceptable cable bend radii of 8” (200mm) is not exceeded.Ensure during fitting that no structural member of the tractor cab or roll bar is drilled ordamaged.The cable rotor control valve lever on cable controlled machines will be assembled as acomponent part of the main bank of controls and therefore shares the same mountingbracket.On electric machines with cable operated rotor control valve the lever will be supplied as a‘standalone’ unit with its own individual mounting bracket – this should be fitted in thesame manner as above adopting the same precautions pertaining to attachment and cableruns.Electric ControlsDepending on the particular type of control, electric units are supplied either with amounting bracket or a mounting pillar which should be bolted to the internal mud wing orcab cladding in a suitable convenient location that offers ease of use without interferingwith normal tractor operation. Mounting pillars can be bent or twisted to achieve acomfortable working position. Ensure during fitting that no structural member of the tractorcab or roll bar is drilled or damaged.The power supply cable should be connected directly to the tractors battery - do not usecigarette lighter type connections as these prove to be sporadic and unreliable for controlapplications. Control units are 12 volt DC operated; the brown lead is positive (+) and theblue lead is negative (-).Proportional Armrest ControlsV4 proportional controls comprise of 2 units; the main control box and the armrest controlunit. The control box is supplied with a mounting bracket and suction cup assembly thatallows the unit to be mounted on the window of the tractor cab – ensure the surface usedis clean and dry and that the unit is mounted in a position where it does not obstructoperator vision. The armrest control is designed to slide over the armrest of the tractorseat and is held in place with the fixing straps provided.The power supply cable should be connected directly to the tractors battery - do not usecigarette lighter type connections as these prove to be sporadic and unreliable for controlapplications. Control units are 12 volt DC operated; the red lead is positive (+) and theblack lead is negative (-).17

FLAILHEAD ATTACHMENTFor ease of attachment and safety this procedure is best performed on a firm level site.With the tractor parked alongside the flailhead operate the controls of the machine toposition the pivot bracket of the machines head angling mechanism directly behindflailhead with the base of the hose tray (or junction bracket) parallel to the ground.Manoeuvre the flailhead backwards on its roller until the heads attachment bracket isadjacent to the machines pivot bracket. Fit the 4 attachment bolts through the bracketsfrom the arm side - if the holes are mis-aligned carefully operate the angling ram until theholes correspond.WARNING: Ensure all persons remain at a safe distance whilst operating the anglingfunction as the geometry of the head angling mechanism produces several pinch risk areas.With the attachment bolts correctly located through the brackets fit the self-locking nutsand tighten alternately until the brackets are drawn flush before finally tightening them to atorque setting of 203Nm (150ft.lbs).Flailhead Hose AttachmentWith the flailhead attached to themachine the hydraulic hoses cannow be connected – refer todiagrams opposite. Upper port ‘A’on the motor connects to junctionbracket point ‘A’ on the arm andlower port ‘B’ on the motorconnects to junction bracket point‘B’ on the arm.Note: If a hose tray is alreadyfitted to the arm it will need to beremoved to allow the hoses tobe connected to the junctionbracket – ensure the hose tray isreplaced once the hoses havebeen connected.18

RUNNING UP PROCEDURECAUTION! Before initial use of a new machine, all lubrication points must begreased and the gearbox and oil tank levels checked and where required toppedup before attempting to use the machine. See maintenance section for details.‘Running Up’ the MachineEnsure that the rotor control valve is in "STOP" position.Start tractor, engage PTO and allow the oil to circulate through the return l ine filter forabout 5 minutes without operation of the armhead control lever.Operate the armhead levers through their complete range ensuring that all movements arefunctioning correctly.Place the flail head at a safe attitude and move the rotor control to "START" position; afterinitial fluctuation the rotor should settle to a steady speed.Increase PTO speed to approximately 3<strong>60</strong>RPM and run for a further fi ve minutes beforedisengaging and stopping tractor.Check the hose runs and observ e that they are free from any pinching, chaffing, strainingor kinks.Re-check the oil level in the tank-and top up as necessary.EMERGENCY STOPPINGIn all emergency situations machine operation and functions must be stopped immediately;Stop PTO operation using the tractor controls then immediately kill electrical power to themachine using the Off (Emergency Stop) switch on the machine’s control unit.WARNING: Auto-Reset MachinesWhen the Auto-Reset feature is active the machines arm set is capable ofunintentional movement even when the PT O is switched off and stationary.Always ensure that electrical power to the machine is switched off using th eOff (Emergency Stop) switch on the machine’s control unit in emergencysituations and/or when the machine is not being operated.WARNING: Cable Operated MachinesIn certain conditions, and/or if the Auto -Reset feature is active, the arm setson cable operated machines possess the potential to move unintentionally ,even when the PTO is switched off and st ationary, if the levers were to beaccidentally operated. Care must be adopt ed to avoid any movement of thelevers when the machine is not being operated. Ensure arm sets are loweredfully to the ground when the machine is parked up or not in use.19

PRE-WORK PREPARATION & PRECAUTIONSIMPORTANT: Always read the book first before attempting to operate the machine –practise operating the machine, without the rotor running, in a safe open space until youare fully familiar with all controls and functions of the machine. Only begin using themachine for work when you are confident that you have mastered the controls andoperation sufficient for safe use of the machine.CAUTION: Care must always be taken when working with the flailhead close in toavoid contact with the tractor.Pre-work Machine ChecksPrior to use of the machine always check all bolts are tight and that the torque figures arecorrect for the specific locations indicated below:52 NmMotor BoltsRoller End Capscrews203 NmRotor BoltsFlail BoltsRoller Bracket BoltsGeneral Work PrecautionsInspect the work area prior to operation, remove any hazardous materials and note anyimmovable objects - it may also be a wise precaution to mark immovable hidden hazardswith a visible marker that can easily be seen from the operating position in the tractor.If the type of work being undertaken makes this important precaution impractical, alwaysmaintain a high degree of alertness and restrict the tractors forward motion to a speed thatallows sufficient time to stop the tractor or avoid the hazard before contact is made.General Working PracticeIt is the operator’s responsibility to develop safe working procedures;Always:▲ Be aware of potential hazards in the vicinity of the work area.▲ Ensure all guards are fitted correctly and in good condition.▲ Disengage PTO before stopping the engine.▲ Wait until the flail has stopped running before leaving the tractor seat.▲ Disengage the PTO, stop the engine, remove and pocket the key before making anyadjustments to the machine.▲ Check frequently that all nuts and bolts are tight.▲ Keep bystanders at a safe distance.20

REMOVAL FROM TRACTORDANGER!READ CAREFULLY BEFORE COMMENCING TO REMOVE THE MACHINE FROMTHE TRACTOR.THE ORDER OF THE FOLLOWING STEPS MUST BE FOLLOWED EXACTLYDISCONNECTING THE TOP LINK MUST BE THE LAST OPERATION PRIOR TODRIVING THE TRACTOR AWAY FROM THE MACHINE.WARNING!Do not operate quadrant lever or machine controls through the rear cab window whilststanding on or amongst linkage components. Always seek assistance.Select a firm level site for parking the machine.Replace parking legs in their sockets and secure in their lowest position.Raise the machine on the tractor linkage until the weight is taken off the stabiliser.Remove the lower stabiliser pins.Unscrew the lift ram tap.Lower the machine to be ground.Extend the arms and place the flail head on the ground at half reach.Disengage tractor PTO and remove.Disconnect stabiliser bars and/or loosen check chains as applicable.Remove control unit from tractor cab and stow in a safe location clear of the ground.Disconnect the stabiliser from the tractors top hitch position.Remove draft link pins and carefully drive tractor clear of the machine.STORAGEIf machine is to be left standing for an extended period of time, lightly coat the exposedportions of the ram rods with grease. Subsequently, this grease should be wiped off beforethe rams are next moved.If the machine has to be stored outside tie a piece of tarpaulin or canvas over the controlassembly, do not use a plastic fertilizer bag which could lead to rapid corrosion.21

OPERATION<strong>Operator</strong> GuardMachine GuardsBefore each period of work, check that all the relevant tractor and machine guards are inplace and in good working condition.Small splits and abrasions on the lower edges of the flail head rubber flaps arepermissible, but should one or more of these cuts or splits become fifty per cent or more ofthe flap height they should be replaced immediately as they will have become ineffectivefor debris containment.<strong>Operator</strong> SafetyDuring operation all the tractor windows should be kept firmly closed with the exception ofthe rear window which may be opened only to the extent that is sufficient to allow entry ofelectrical or operating cables for the machine into the cab.Should the tractor not be fitted with a 'quiet' cab ear defenders must be worn at all times,failure to heed this warning may result in permanent damage to hearing.Although in normal circumstances a working machine or rotating parts should never beapproached it is an additional wise precaution to avoid wearing loose or flapping clothesespecially scarves and neckties whilst in close proximity to a machine.The operator should continually guard himself and others from complacency that can arisefrom familiarity. Never attempt to take 'short cuts', always follow the correct proceduresdiligently and abide by the restrictions imposed by safety considerations.REMEMBER: there is only one right way - the safe way!22

CABLE CONTROLSCable controlled machines are supplied with a control unit of the type shown below – theparticular version will be depend ent on the specific ation and features of the machine.Versions differ primarily in the number of armhead c ontrol levers assembled within t hecontrol bank – some versions will have the rotor control lever assembled alongs ide thearmhead control levers as shown below left and others will be supplied with the r otorcontrol lever as a ‘standalone’ unit with its own individual mounting bracket.The armhead control levers all move in a forwards and backwards direction eac hcontrolling a specific arm function with the exception of the auto reset lever which operatesonly in the backward direction (from central ‘off’ position to the backwards ‘on’ position).Where applicable, if a machine is fitted with the optional lift fl oat feature, operation of thelift float will be v ia an additional electrical switch which will n eed to be installed in aconvenient location in the tractor cab.Basic Cable Control UnitCable Control Unit with Auto ResetLOCATION & FUNCTION OF CONTROLS1. Arm Lift Control2. Arm Reach Control3. Head Angle Control / Angle Float Selection4. Arm Slew Control5. Rotor Control6. Auto Reset (where applicable)7. Midcut/VFR (where applicable)23Cable Control Unit with Auto Reset & MidcutNOTE: The illustrations on the following pages show the method of operating all possible functions –depending on individual specifications some features may not be present on your particular machineand therefore will not be applicable.

ARM OPERATIONAutoReset24

Rotor ControlRefer to specific cable rotor control sectionfor additional information on rotor operationMidcut/VFR ModelsFLOAT OPERATION (Angle Float standard/ Lift Float optional)HEAD ANGLE FLOAT -Push angle lever fullyforward into the detentposition.A) Angle Float OFF B) Angle Float ONLift Float (where applicable)A) Lift Float OFF B) Lift Float ON25

CABLE ROTOR CONTROLOn cable rotor control machines the rotor is operated by the lever shown below – from theupright ‘off’ position pushing the lever forward switches the rotor on for downhill cutting andpulling the lever backwards switches the rotor on for uphill cutting. The small pivot lockinglever mounted on the side of the control assembly rotates through 180° to lock the rotor ina specific cutting direction – this is a safety feature to avoid changes of rotor directionwithout first stopping the rotor. To change the direction of cut the rotor lever must beplaced in the upright ‘off’ position; when the rotor has stopped rotating completely the pivotlocking lever can be turned to the opposing position allowing the control lever to beoperated for opposite cutting direction.On some cable operated machines the rotor control lever will be assembled as part of themain bank of controls, whereas on others and all electric models it will be supplied as a‘standalone’ unit with its own mounting bracket.UPHILL CUTTINGLockDOWNHILL CUTTINGLockCAUTION: Ensure the rotor has stopped turning completely before attempting to changedirection - When switched off a rotor can continue to ‘freewheel’ under its own momentumfor up to 40 seconds before stopping.26

ELECTRIC SWITCHBOX CONTROLSMachines with Electric Switchbox Controls will be s upplied with one of the control unitsshown below, the particular version will be dependent on the spec ification of the machine;machines fitted with c able rotor control will use the unit shown left whilst machines wit helectric rotor control will use the unit shown right – the only differences between the unit sis that the latter has 2 addition switches fitted for operation of the electric rotor control.Cable Rotor Control Version▼Electric Rotor Control Version▼LOCATION & FUNCTION OF CONTROLS1. Arm Lift Control2. Arm Reach Control3. Flailhead Angle Control4. Arm Slew Control5. Tele/Midcut/VFR Control (Applicable models only)A. Power On/OffB. Auto ResetC. Head Float - Angle/Lift (Option)D. Rotor On/Off (Electric RCV models)E. Rotor Direction (Electric RCV models)Powering the ControlsActivation of power to the control unit is by operation of switch ‘A’ as shown below:Press the switch down for Power ON (LED light on)Press the switch up for Power OFF (LED light off)PowerONPowerOFF27

ARM OPERATIONAutoResetMidcut or VFR Models only28

HEAD FLOAT OPERATION (Angle Float standard / Lift Float optional)Angle Float OFFLift Float OFFAngle Float OFFLift Float ONAngle Float ONLift Float ONROTOR OPERATION – Electric Rotor Control Models onlyNOTE: The following section relates to machines with Electric Rotor Control only – for Cable RotorControl models refer to the cable rotor control section.Selection of Rotor Cutting DirectionUphill CuttingDownhill Cutting29

Switching the Rotor OnFor safety reasons, to prevent accidental starting of the rotor, the ‘Rotor On’ switch cannotbe activated in a single operation or without first selecting the direction of cut – theprocedure for starting the rotor is as follows:Select the required cutting direction - the Rotor On/Off Switch (D) must then be switchedupwards and held in position for a minimum of 8 seconds before switching it into the fullydown ‘on’ position where it will remain until it is switched off. When the switch is moved tothe down position the red LED light below the switch will be lit to signify the rotor is on – ifthe LED does not light the switch was not held in its up position for long enough and therotor will not have started, repeat the process again holding the switch upwards for alonger period.Rotor StartSwitching the Rotor OffStopping the rotor is performed by switching either the Rotor Power Switch (D) or theRotor Direction Switch (E) to the central (off) position – the red LED light will go out tosignify the rotor has been switched off.Rotor StopCAUTION: When the rotor is switched off it will continue to ‘freewheel’ under its ownmomentum for up to 40 seconds before finally coming to a standstill – do not leave thetractor cab or attempt to approach the flailhead until the rotor has stopped turningcompletely.Alternative Rotor Stop30

ELECTRIC MONOLEVER CONTROLSMachines with Electric Monolev er Controls will be supplied with one of the control unit sshown below, the particular version will be dependent on the spec ification of the machine;machines fitted with c able rotor control will use the u nit shown left whilst machines wit helectric rotor control will use the unit shown right – the only differences between the unit sis that the latter has 2 addition switches fitted for operation of the electric rotor control.Cable Rotor Control Version▼Electric Rotor Control Version▼LOCATION & FUNCTION OF CONTROLS1. Arm Lift Control2. Arm Reach Control3. Flailhead Angle Control4. Arm Slew Control5. Tele/Midcut/VFR Control (Applicable models only)A. Power On/Off (Emergency Stop)B. Auto ResetC. Head Float - Angle/Lift (Option)D. Rotor On/Off (Electric RCV models)E. Rotor Direction (Electric RCV models)Powering the ControlsActivation of power to the control unit is by operation of switch ‘A’ as shown below:Rotate the switch clockwise to Power ON (LED light on)Press the switch to Power OFF or Emergency Stop (LED light off)PowerONPowerOFF31

ARM OPERATIONAutoResetMidcut or VFR Models only32

HEAD FLOAT OPERATION (Angle Float standard / Lift Float optional)Angle Float OFFLift Float OFFAngle Float OFFLift Float ONAngle Float ONLift Float ONROTOR OPERATION – Electric Rotor Control Models onlyNOTE: The following section relates to machines with Electric Rotor Control only – for Cable RotorControl models refer to the cable rotor control section.Selection of Rotor Cutting DirectionUphill CuttingDownhill Cutting33

Switching the Rotor OnFor safety reasons, to prevent accidental starting of the rotor, the ‘Rotor On’ switch cannotbe activated in a single operation or without first selecting the direction of cut – theprocedure for starting the rotor is as follows:Select the required cutting direction - the Rotor On/Off Switch (D) must then be switchedupwards and held in position for a minimum of 8 seconds before switching it into the fullydown ‘on’ position where it will remain until it is switched off. When the switch is moved tothe down position the red LED light above the switch will be lit to signify the rotor is on – ifthe LED does not light the switch was not held in its up position for long enough and therotor will not have started, repeat the process again holding the switch upwards for alonger period.Rotor StartSwitching the Rotor OffStopping the rotor is performed by switching either the Rotor Power Switch (D) or theRotor Direction Switch (E) to the central (off) position – the red LED light will go out tosignify the rotor has been switched off.Rotor StopCAUTION: When the rotor is switched off it will continue to ‘freewheel’ under its ownmomentum for up to 40 seconds before finally coming to a standstill – do not leave thetractor cab or attempt to approach the flailhead until the rotor has stopped turningcompletely.Alternative Rotor Stop34

XTC (Mk2) PROPORTIONAL SWITCHBOX CONTROLS (5 Service Models)Machines with XTC Mk2 Proportional Controls (5 service models) will be supplied with thecontrol unit shown below. The units for both el ectric and cable c ontrolled rotor machinesare identical except that for cable versi ons the rotor control switches B, C & D (shownbelow) will not provide a function as rotor operat ion will be controlled by a separate cablelever unit (refer to specific cable rotor control page for operation details of that unit).LOCATION & FUNCTION OF CONTROLS1. Arm Lift Control2. Arm Reach Control3. Head Angle Control4. Arm Slew Control (Default Mode)5. Tele*/Midcut*/VFR* Control (Default Mode)* Applies to the specific model onlyA. Power On/Off (LED ‘a’ indicates status)B. Rotor Start (Uphill Cutting Direction)C. Rotor Start (Downhill Cutting Direction)D. Rotor StopE. Auto ResetF. Head Angle Float On/OffG. Lift Float On/Off (Option)Note: 2 sets of control buttons are installed on each side of the unit for operation of Angle Float &Lift Float, both sets of buttons and their LED’s are linked and therefore perform exactly the samefunction; they are installed to allow for operator preference.LED LightsAn LED light adjacent to each c ontrol button reports the status of that particular function –when the function is selected the LED light will illumina te to confirm the function is activ e;the light will switch off on de-selection of that function.Powering the ControlsActivation of power to the control unit is by operation of the red button switch ‘A’ as sh ownbelow:Rotate clockwise for Power ON (LED light on)Press for Power OFF / Emergency Stop (LED light off)35

ARM OPERATIONMidcut or VFR Models only36

HEAD FLOAT OPERATIONAngle Float (Standard Feature)Lift Float (Optional Feature)ROTOR OPERATION – Electric Rotor Control Models onlyNOTE: The following section relates to machines with electric rotor control only – for cable rotorcontrol models refer to the specific cable rotor control section.Rotor Start (Selection of Rotor Cutting Direction)Select rotor start for required direction (LED will light to indicate the active direction).Uphill CuttingDownhill Cutting37

Switching Rotor DirectionWith the rotor running, changing the rotor cutting direction can only be achieved after firstoperating ‘rotor stop’, when stop has been selected the specific direction button can thenbe operated to command the rotor to switch to the desired direction. NOTE: This functionhas a built in time delay of approximately 8 seconds - this is a machine protection featurethat allows the rotor sufficient time to de-accelerate before restarting in the oppositedirection. The LED light of the active cutting direction will flash on and off during theslowing down period, when the direction has changed the LED for the new direction will beilluminated.Switching the Rotor OffStopping the rotor is performed by operation of the rotor stop button as illustrated below.When rotor off has been selected the LED light above the button of the active cuttingdirection will flash on and off for approximately 8 seconds to signify that the rotor has beenswitched off, after this 8 second period the light will go off completely. NOTE: The rotor willcontinue to rotate under its own power until it finally comes to a standstill.CAUTION: When the rotor is switched off it will continue to ‘freewheel’ under its ownmomentum for up to 40 seconds before finally coming to a standstill – do not leave thetractor cab or attempt to approach the flailhead until the rotor has stopped turningcompletely.38

V4 PROPORTIONAL CONTROLSPOWER ON / OFF (Emergency Stop)Rotate Clockwise to Power On – control unit will emit a single beep and screen will displaythe selected PTO speed, software version and the <strong>McConnel</strong> name. Press to Power Off.ROTOR START – Uphill CuttingThis button starts the rotor for ‘uphill’ cutting – whenthe button is pressed the control unit will emit asingle beep, the LED light will illuminate and thescreen will momentarily display ‘FLAIL START ’.ROTOR START – Downhill CuttingThis button starts the rotor for ‘downhill’ cutting –when the button is pressed the control unit will emit asingle beep, the LED light will illuminate and thescreen will momentarily display ‘FLAIL START ’.ROTOR STOPThis button stops the rotor – when the button ispressed the control unit will emit a single beep andthe screen will momentarily display ‘FLAIL STOP ’– the LED lights above both rotor start buttons will beilluminated for approximately 10 seconds, during thisperiod the rotor start buttons will be disabled to allowsufficient time for the rotor to power down. When theLED lights go out the rotor direction can be changedor the rotor allowed to stop.WARNING: The LED lights going out do notindicate that the rotor has stopped rotating, itsignifies only that the oil flow to the rotor has ceased sufficient for the direction of rotationto be changed - therefore when stopping a rotor it must be noted that it will continue tofreewheel for a considerable length of time after the stop button has been activated, insome case this can be up to 40 seconds.39

HEAD ANGLE FLOATThere are 2 methods available for selection and de-selection of this function; activation viathe control unit - refer to #1 below, or activation via the joystick controls - refer to #2 below.1. Pressing the Head Angle Float button – when activated the control unit will emit asingle beep, the LED light will illuminate and the screen will momentarily display‘ANGLE FLOAT ’ pressing the button again will deselect the function – the controlunit will emit a single beep, the LED light will go out and the screen will momentarilydisplay ‘ANGLE FLOAT X’.2. Press and hold in the lower frontal button(B1) on the joystick control and roll the lefthand thumbwheel (T1) forwards – thecontrol unit will emit a single beep, theLED light will illuminate and the screen willmomentarily display ‘ANGLE FLOAT ’.To deselect press and hold in the lowerfrontal button (B1) on the joystick controland roll the left hand thumbwheel (T1)backwards – the control unit will emit asingle beep, the LED light will go out andthe screen will momentarily display‘ANGLE FLOAT X’.NOTE: When selecting or deselecting thefunction, the thumbwheel (T1) should beallowed to return to its centre position beforereleasing the lower frontal button (B1).NOTE: By default operation of thumbwheels T1 and T2 in conjunction with button B1 activatesHead Angle Float and EDS/Lift Float respectively. These controls can, if required, be swappedover so that the thumbwheels operate the opposing functions – this procedure is performed byaccessing the settings menu on the control unit via the screen and menu buttons.40

EDS FUNCTION (EDS Models) / LIFT FLOAT (Non EDS Models)There are 2 methods available for selection and de-selection of this function; activation viathe control unit - refer to #1 below, or activation via the joystick controls - refer to #2 below.1. Pressing the EDS / Lift Float button will activate the relevant function – when activatedthe control unit will emit a single beep, the LED light will illuminate and the screen willmomentarily display ‘LIFT FLOAT’. Pressing the button again will deselect thefunction – the control unit will emit a single beep, the LED light will go out and thescreen will momentarily display ‘LIFT FLOAT X’.Press and hold in the lower frontalbutton (B1) on the joystick controland roll the right hand thumbwheel(T2) forwards – the control unit willemit a single beep, the LED light willilluminate and the screen willmomentarily display ‘LIFT FLOAT’. To deselect press and hold inthe lower frontal button (B1) on thejoystick control and roll the righthand thumbwheel (T2) backwards –the control unit will emit a singlebeep, the LED light will go out andthe screen will momentarily display‘LIFT FLOAT X’.NOTE: When selecting or deselectingthe function, the thumbwheel (T2)should be allowed to return to its centreposition before releasing the lowerfrontal button (B1).All models with v4.08 software onwards: With the function engaged subsequentoperation of button B1 on the joystick or the [] button on the control unit will alternatelydisable and enable all active floats.EDS models with pre v4.08 software: With the function engaged and the rotor runningEDS settings (SOFT – MED – HARD) will automatically be displayed on the control unitscreen and can be scrolled through using button B1 on the joystick or the tick [] button onthe control unit, if the rotor is not running the EDS settings can manually be viewed on thescreen by pressing either [◄] [►] buttons on the control unit and scrolling to the EDS workscreen.41

AUXILIARY FUNCTION CONTROLThere are 3 possible types of auxiliary service control as described in A, B & C below – theparticular type used will be dependant on the build specification of the machine. Controloperation of the function for all types remains the same (see below).A) Diverter Valve System Utilising an Existing Service (Physical Diverter Valve)The control selects either of the two diverter valves for the operation of additionalequipment that may be fitted to the machine such as: Directional Ram, Orbiter Head Kit,Hydraulic Roller etc.B) 6/7 Service Manifold Systems (Electronic Diverter Valve)Only available on stackable manifold systems either as a factory fitted option or as anaftermarket kit, in the case of the latter ‘D1 and/or D2 PROP’ will need to be changed from‘N’ to ‘Y’ within ‘options’ of the setup menu on initial installation of the kit.C) Integrated Debris BlowerOperated by D1 on machines with standard arm or D2 on machines with Tele, Midcut orVFR arms.There are 2 methods of control available for selection and de-selection of the functions;activation via the control unit - refer to #1 below, or activation via the joystick controls -refer to #2 below.1. Pressing the button momentarily will select Diverter Valve #1 – when activated thecontrol unit will emit a single beep, the LED light will illuminate and the screen willmomentarily display ‘DIVERTER VALVE 1 ’. Pressing the button again momentarilywill deactivate diverter #1, the screen will display ‘DIVERTER VALVE 1 X’Holding the button in for 2 seconds will select Diverter Valve #2 – when selected itremains active until it is subsequently deselected by holding the button in again for 2seconds.2. Pressing the upper frontal button (B2) onthe joystick momentarily will select DiverterValve #1 – when activated the control unitwill emit a single beep, the LED light willilluminate and the screen will momentarilydisplay ‘DIVERTER VALVE 1 ’. Pressingthe button again momentarily willdeactivate diverter #1, the screen willdisplay ‘DIVERTER VALVE 1 X’Holding button (B2) in for 2 seconds willselect Diverter Valve #2 – when selected itremains active until it is subsequentlydeselected by holding the button in againfor 2 seconds.42

SLEW – TELE / MIDCUT / VFR SWAPThis function swaps over the controls used to operate Slew and Tele/Midcut/VFR. Bydefault, Slew operation is performed with the right hand thumbwheel (T2) andTele/Midcut/VFR operation with the [◄] [►] buttons on the control unit - in the swappedmode these will be the opposite way around and the LED on the control unit will be lit toindicate that the swapped mode is selected.Swapping these controls is performed via the control unit - refer to #1 below. On machinesinstalled with pre v4.08 software the same function could also be performed via thejoystick controls – for these models only refer also to #2 below.1. Press the swap button once to select swap mode – when activated the control unit willemit a single beep, the LED light will illuminate and the screen will momentarily display‘SLEW/TELE SWAP ’. Pressing the button again will deselect the function – thecontrol unit will emit a single beep, the LED light will go out and the screen willmomentarily display ‘SLEW/TELE SWAP X’.Models with pre v4.08 software only2. Press the joysticks lower frontal button (B1)once to select swap mode – when activatedthe control unit will emit a single beep, theLED light will illuminate and the screen willmomentarily display ‘SLEW/TELE SWAP’.De-selection is with subsequent use of thesame button - the control unit will emit asingle beep, the LED light will go out andthe screen will momentarily display‘SLEW/TELE SWAP X’.43

AUTO RESETThis button is for the selection and de-selection of the Auto Reset function – pressing thebutton once will activate Auto Reset, the control unit will emit a single beep, the LED lightwill illuminate and the screen will momentarily display ‘AUTO RESET ’. Pressing thebutton again will deselect the function – the control unit will emit a single beep, the LEDlight will go out and the screen will momentarily display ‘AUTO RESET X’.44

V4 JOYSTICK CONTROLS - Buttons & Thumbwheels OperationNOTE: By default operation of thumbwheels T1 and T2in conjunction with button B1 activates Head AngleFloat and EDS/Lift Float respectively. These controlscan, if required, be swapped over so that thethumbwheels operate the opposing functions – thisprocedure is performed by accessing the settingsmenu on the control unit via the screen and menubuttons.LH/RH Swap Shortcut; Press and hold & X on Control Unit for 3 seconds (unit will ‘bleep’ to confirm).FLOAT SELECTION & DE-SELECTIONOperate thumbwheels to their furthest points (+ or -) to select or deselect float functions.ANGLE & SLEW OPERATIONRotate thumbwheels in required direction.DIVERTER VALVE SELECTIONDiverter selection is via button B245

ARMHEAD OPERATION – JOYSTICK CONTROLS46

TELE / MIDCUT / VFR OPERATION – JOYSTICK CONTROLS (Diverted Mode)47

V4 CONTROL UNIT – Screen Access & Menu ButtonsPower on/off switch (E/Stop)Speaker (audible confirmation)Control unit emits an audible confirmation ‘beep’ when the buttons are pressed.Command Button []Command Button [X]Navigate Forward Button [>] Navigate Back Button [

V4 CONTROL UNIT – LED Screen Display & FunctionsIMPORTANT: Under no circumstances should a V4 Control Unit be connected to a V3 ACB (AuxiliaryControl Box). Dedicated V3.5 & V4 Upgrade Kits are available from <strong>McConnel</strong> Limited – contact yourlocal dealer or <strong>McConnel</strong> direct for available options and specific advice on this subject.Rotate the ON/OFF switch on the control unit clockwise to power up controls - unit will emita single beep and the LED screen will light up. Note: 12 Volts at the battery is required forthe unit to function correctly.1. Screen will initially display the ‘<strong>McConnel</strong>’ name alongwith the selected PTO speed and the software versionsinstalled on the Armrest and the Control Boxrespectively.2. Pressing the scroll forward [►] button once will displaythe rotor running times screen. ‘TOT’ displays theoverall total running time of the rotor which is acumulative total and cannot be reset. ‘JOB’ is a ‘trip’total for the current rotor running time and can be resetto zero by pressing and holding the [X] button for 3seconds.3. Pressing either of the ‘Rotor On’ buttons will activatethe ‘egg timer’ icon and display the rotor on image.4. Pressing the EDS Lift float button will turn on the EDS(EDS Lift Float machines only). Then SOFT, MED orHARD will be added to the running screen.5. Pressing the tick [] button when EDS is turned on willscroll through the EDS work settings of SOFT, MED orHARD. This may also be operated via button B1 on thejoystick.6. Pressing scroll forward [►] button will now display theactual Tractor PTO running speed.7. Scrolling forward [►] again displays the Power Monitorscreen.Scrolling backwards [◄] will display the screens in theopposite order.49

POWER MONITORWhen displayed the power screen will indicate to the operator the level of power beingdemanded by the cutting head – an ascending graphic indicates the power demand statusfrom minimum on the left of the screen to maximum on the right.Power Status – Low DemandPower Status – High DemandWhen the power demand approaches the maximum limit an audible warning will alert theoperator to indicate that the rotor is under excess load and at risk of ‘stalling’ – when thisaudible warning sounds the operator should reduce the forward tractor speed to protectthe machine and regain efficient cutting power – the audible warning will cease when thepower demand returns to an acceptable level.In certain cases, cutting materials of extreme density may cause an increase in the powerusage to the ‘warning level’ – in these types of conditions raising the cutting head into aless dense area of the material will regain an acceptable power demand. It is advisablethat work in problematic high density materials be performed in several passes, loweringthe cutting head slightly on each pass until the required cut height is achieved.ADDITIONAL CONTROL & SCREEN SETTINGSAdditional settings available to the operator can be found within the settings menu of thecontrol unit and accessible via the screen and menu buttons on the control panel.Access is gained by simultaneously pressing the scroll [◄] [►] buttons on the controlpanel until the unit emits a ‘beep’ and the setup screen appears on the LCD - the featurescan then be ‘scrolled’ to (forwards or backwards) by subsequent operation of either of thescroll [◄] [►]buttons. When the required screen is reached the tick [] button should bepressed to enter the settings menu for that feature.THUMB (Thumbwheel Switching) – this allows the operator to ‘swap over’ the left andright thumbwheel functions so that they control the opposing features. In most cases thissetting will be dictated by the operators’ personal preference and once chosen theoperator will keep it in the selected mode.Options are ‘Normal’ or ‘Swap’ – selection is by ‘highlighting’ the required option usingeither of the scroll [◄] [►] buttons – the feature is then activated using the tick [] button.Pressing the [X] button exits the screen settings and returns to the normal work screen.LED (Screen Contrast) - this setting allows the operator to adjust the contrast level of theLED display – the feature affords the option to increase or decrease the contrast level tosuit differing lighting conditions; this is particularly useful on dull or sunny days wherereduced or increased natural light can affect screen clarity.Options are ‘Increase Contrast’ or ‘Decrease Contrast’ – selection is by ‘highlighting’ therequired option using either of the scroll [◄] [►] buttons – once selected that particularoption can then be adjusted in incremental steps by pressing the tick [] button therequired number of times to achieve the desired contrast. Pressing the [X] button exits thescreen settings and returns to the normal work screen.CAUTION: Avoid adjusting the contrast level to a state where the screen cannot be viewed as exitingthe settings menu in this condition may render the LCD unusable as the ‘on screen’ prompts may nolonger be visible to the user.NOTE: Some screen menus are inaccessible to the operator – these are for factory or dealer use onlyand are password protected to avoid inadvertent changes to specific control settings.50