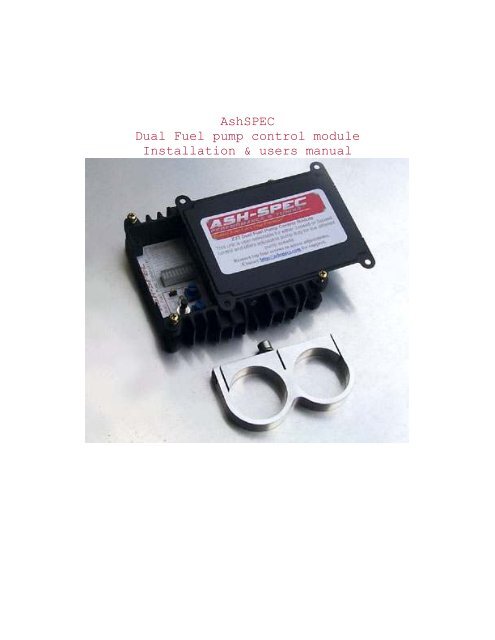

AshSPEC Dual Fuel pump control module Installation & users manual

AshSPEC Dual Fuel pump control module Installation & users manual

AshSPEC Dual Fuel pump control module Installation & users manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The primary purpose for adjustable <strong>pump</strong> duty and speed switching is to preventregulator overrun. Regulator overrun results in excessively high fuel pressures. This iscaused simply by a fuel pressure regulator’s inability to bypass enough fuel back to thetank when large volumes of fuel are being delivered by the <strong>pump</strong>(s).In the stock configuration from Nissan, the single twinturbo <strong>pump</strong> is actually capable ofproducing regulator overrun. This is why Nissan employed the fuel <strong>pump</strong> <strong>control</strong> <strong>module</strong>to vary the speed of the <strong>pump</strong>. By slowing the <strong>pump</strong> speed when fuel demand from theengine is low, fuel pressure can be properly maintained.In the 3-speed twin turbo fuel system setup the <strong>pump</strong> is <strong>control</strong>led as such:Condition1 second after keys turn to ON positionEngine Cranking30 seconds after engine start (above 122F)Engine Temp below 50FBoost is above ~5psiMiddle load, non-idle conditionExcept the abovePumpFULL SPEED (100%)MID SPEEDLOW SPEEDFor the 2-speed NA setups, LOW SPEED is only used for and idle condition. Any otherthrottle position results in full speed operation.SETTING THE DUTY SPEEDS:You will need to have an aftermarket fuel pressure gauge installed into the vehicle inorder to perform the configuration steps outlined below.With the cover plate removed, start the vehicle and allow it to idle for a moment until itswitches into low speed operation. If the <strong>control</strong>ler never switches to low speedoperation after fully warmed up, be sure to check your throttle position sensor’s closedthrottle position switch.Once the <strong>control</strong>ler switches to low speed, note the fuel pressure. <strong>Fuel</strong> pressure in an idlecondition should be ~38psi +/-2psi. Adjust the low speed adjustment until this fuelpressure is achieved. Typical duty cycles for this are around 40%.For 3-speed <strong>users</strong>:Once the low speed is set, depress the mid speed trigger button. This forces the <strong>control</strong>lerinto its mid speed operation. Typical <strong>pump</strong> duty for this load condition is 70%. Set tothis value and perform a road test to monitor fuel pressures. When driving the vehicleyou should note a smooth transition of fuel pressure as throttle opening is increased andboost pressure builds. The increase in fuel pressure should be linear to the increase inboost pressure. The table below reflects the relationship between boost pressure and fuelpressure.

Carefully monitor fuel pressure over the boost range and adjust the <strong>pump</strong> dutyaccordingly for the speed levels to produce a smooth 1:1 boost to fuel pressurerelationship.**NOTE:It is highly recommended to use an aftermarket fuel pressure regulator when running witha dual fuel <strong>pump</strong> configuration, or any other high output fuel system. The factoryregulator unfortunately does not have the bypass volume necessary to produce a smoothconsistent boost vs. fuel pressure dynamic and will result in a “shaky” fuel pressureresponse as the <strong>control</strong>ler switches through its various speeds.