Description of segments 17MarketIn <strong>2009</strong>, the global market for insulation products covered a volume of around CHF 2.1 billion. By2011, growth to CHF 2.4 billion is expected. The most important growth drivers are traction motorsand rotation motors. Traction motors are benefiting from the trend towards urbanisation in China,India and Russia, which is leading to the expansion of the railway systems. In addition, climate protectionrequires the replacement of older diesel engines with modern, electrical locomotives. Therotation motors segment is growing as a result of investment in basic industries such as oil and gasextraction, as well as cement, steel and engineering in China and India. In addition, subsidies foralternative energies are promoting the spread of wind power stations. Around three quarters of theinsulation market is accounted for by Europe and Asia. While the high-voltage area includes themajor globally active power station builders among its customers, the market is more fragmentedin the low-voltage area. <strong>Von</strong> <strong>Roll</strong> Insulation is a global market leader in insulation products and isalso well-positioned in the service business.Highlights <strong>2009</strong><strong>Von</strong> <strong>Roll</strong> Insulation launched an innovation in the area of mica tapes with DryFlex Mica Tape. Thenew product has excellent adhesive features and flexibility, which enables a considerable increasein efficiency in production for customers. The new mica tape product family will go into mass productionin the first quarter of 2010. In the area of liquid products, <strong>Von</strong> <strong>Roll</strong> Insulation brought a newproduct family of environmentally friendly, odour and solvent-free epoxy resin (EP) on to the market.In addition, a polymer was developed under the name UPAC, which can be enriched with variouschemical components. This means that <strong>Von</strong> <strong>Roll</strong> Insulation can offer a wide range of resins withdifferent properties, which are based on the same base material. The areas of use are correspondinglybroad, from industrial motors through to generators for wind turbines. In the area of flexiblelaminates, <strong>Von</strong> <strong>Roll</strong> Insulation was able to significantly increase sales to Asia, in particular for applicationsin electricity generation and transmission, as well as for traction motors.Case study: traction motors<strong>Von</strong> <strong>Roll</strong>’s engineering achievements are usuallyinvisible, hidden away in places like the futuristichigh-speed trains that amaze us interms of how quickly and safely they transportus to our destination. The traction motors arebuilt into the bogies of locomotives and multipleunits, with the motive power being generatedby the rotating, magnetic field of the statorcoil and transferred to the drive wheels via agearbox. The electrical insulation used in transactionmotors is exposed to very high temperaturesand wear, so the high durability of<strong>Von</strong> <strong>Roll</strong>’s insulation materials is a key factor inthe exceptional reliability of the motors.

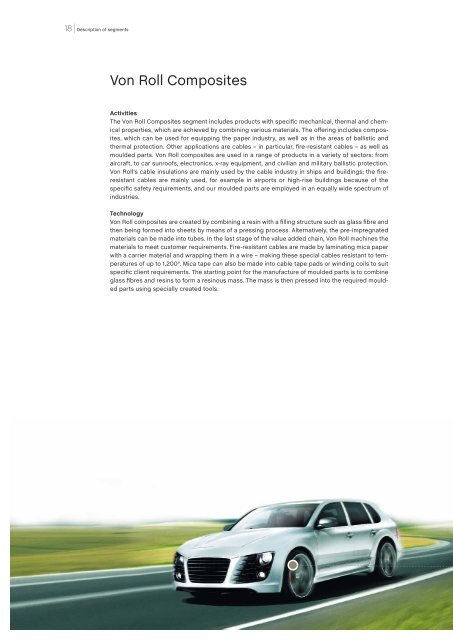

18 Description of segments<strong>Von</strong> <strong>Roll</strong> CompositesActivitiesThe <strong>Von</strong> <strong>Roll</strong> Composites segment includes products with specific mechanical, thermal and chemicalproperties, which are achieved by combining various materials. The offering includes composites,which can be used for equipping the paper industry, as well as in the areas of ballistic andthermal protection. Other applications are cables – in particular, fire-resistant cables – as well asmoulded parts. <strong>Von</strong> <strong>Roll</strong> composites are used in a range of products in a variety of sectors: fromaircraft, to car sunroofs, electronics, x-ray equipment, and civilian and military ballistic protection.<strong>Von</strong> <strong>Roll</strong>’s cable insulations are mainly used by the cable industry in ships and buildings; the fireresistantcables are mainly used, for example in airports or high-rise buildings because of thespecific safety requirements, and our moulded parts are employed in an equally wide spectrum ofindustries.Technology<strong>Von</strong> <strong>Roll</strong> composites are created by combining a resin with a filling structure such as glass fibre andthen being formed into sheets by means of a pressing process. Alternatively, the pre-impregnatedmaterials can be made into tubes. In the last stage of the value added chain, <strong>Von</strong> <strong>Roll</strong> machines thematerials to meet customer requirements. Fire-resistant cables are made by laminating mica paperwith a carrier material and wrapping them in a wire – making these special cables resistant to temperaturesof up to 1,200°. Mica tape can also be made into cable tape pads or winding coils to suitspecific client requirements. The starting point for the manufacture of moulded parts is to combineglass fibres and resins to form a resinous mass. The mass is then pressed into the required mouldedparts using specially created tools.