CONSTRUCTION - VINCI Construction Grands Projets

CONSTRUCTION - VINCI Construction Grands Projets

CONSTRUCTION - VINCI Construction Grands Projets

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>CONSTRUCTION</strong>

<strong>VINCI</strong> <strong>Construction</strong><strong>Grands</strong> <strong>Projets</strong>Our values make it happenAround the world, <strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong>designs and builds large civil engineering structures andbuildings. Its high level of expertise and strong engineeringand management capabilities, combined with a responsiveorganisational structure and a policy of forging partnershipswith local companies, enable it to provide solutions thatare both global and modular to meet the wide-rangingneeds of public and private sector clients, from technicalsupport to the provision of turnkey projects and maintenance.<strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong> is a subsidiary of <strong>VINCI</strong>, theworld leader in concessions, construction and related services.Our visionThe men and women of <strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong>,exemplary inheritors of the great tradition ofthe master builders, execute throughout the worldthe major infrastructure projects of tomorrow.Our values- Excellence- Employee recognition- Safety- Individual responsibility- Innovation- ProfitSafetySAFETY FIRST puts people firstProtecting the people in our teams is our over-ridingconcern, and it also protects our know-how, experienceand skills. It is part and parcel of our management approach,and a source of progress. It fosters high quality work.It is an essential factor in ensuring our personnel are happyin their company and it contributes to customer satisfaction.Our “zero accident” policy and the resulting statisticshave been repeatedly acclaimed by our clients.The company has been awarded numerous certificatesin recognition of its efforts towards safety, such asthe certificate for the 3 million job hours workedwithout any lost time accident on the Idku project.

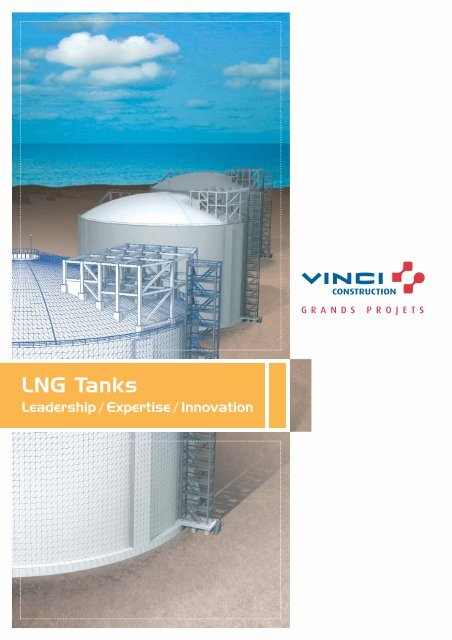

Our expertiseWith over twenty years of experience in LNG tanks,<strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong> applies its expert skillsand ingenuity to the design and construction phases,pooling the knowledge of its teams to efficientlyexecute both civil and mechanical aspects of a project.With its unparalleled know-how, ongoing search for themost innovative and cost-effective solutions, andexcellent guarantees, <strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong>is a key player in the LNG tank market.Committed to innovationEvery project is unique, which is why we harness ourcreativity, using cutting-edge technology and modelingsoftware developed in our laboratories to elaboratecustomized solutions that meet even the most complexrequirements.Our projectexecution approach- Safety first- Use of local resources as a top priority- Successful training of local management andmanpower to international standards- Continuous improvement focus, including integratedfeedback, to enhance design in the post-project phase- Close coordination with clients throughout theproject’s execution towards early completion- Tight project schedules met through internationalprocurement experience

An international track record<strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong>can rely on branches and worksitesworldwide to respond flexibly and speedily toclients needs and to adapt to verydifferent configurations with the mobilityrequired by constantly changing markets.<strong>VINCI</strong> <strong>Construction</strong><strong>Grands</strong> <strong>Projets</strong>LocationsLNG TanksSince completing its first tank inFos-sur-Mer in southern France in 1978,<strong>VINCI</strong> <strong>Construction</strong> <strong>Grands</strong> <strong>Projets</strong> hascontinued to expand its operations in thissteadily growing market.FOS-SUR-MER,FRANCE1976-1978This 80,000 m 3 reservoir, owned byGaz de France, was the first tank everbuilt to include a seismic isolator.HUELVA,SPAIN1987-1988 and 1990-1991ENAGAS commissioned a firstcryogenic reservoir of 60,000 m 3 in1987. This was followed by a secondproject, in 1990, for a second tank, thisone 100,000 m 3 .RAS LAFFAN,QATAR1995-2000 and 2004-2007The first contract involved theconstruction of three 140,000 m 3 tanksfor Ras Laffan LNG Co. Ltd.The second project, currently underway,will provide Qatar with its first reservoir(tank n°6) incorporating an inventivefoundation system. This tank, which isalso being built for RasGas, will hold acapacity of 140,000 m 3 .

RUWAIS,UNITED ARAB EMIRATES1979-1981TERNEUZEN,NETHERLANDS1980-1982MONTOIR,FRANCE1981-1983DAS ISLAND,UNITED ARAB EMIRATES1981-1985This contract for the Abu DhabiNational Oil Company involvedthe construction of four 60,000 m 3LPG tanks.This project involved engineering oftwo LPG tanks, 50,000 m 3 each, forDow Chemical.This tank, built for Gaz de France overa three-year period, can contain120,000 m 3 .This project, comprising seven tanks,included both LNG (3 X 80,000 m 3 )and LPG (4 X 50,000 m 3 ) tanks.The units, developed for the Abu DhabiNational Oil Co., were completed in 1985.BONNY ISLAND,NIGERIA1996-1999IDKU,EGYPT2002-2005COSTA AZUL,MEXICO2005-2007BRINDISI,ITALY2005-2008This project involved the constructionof two tanks, commissioned by NNPC,with a capacity of 84,000 m 3 each.The two Idku tanks, 140,000 m 3 each,were delivered to ELNG three monthsahead of schedule, after a mere35 months of construction.This project, located in an area ofsevere seismic activity, comprises twoLNG full containment tanks of 160,000 m 3each and an unloading dock. Built forSempra Energy, the tanks will be the firstones completed within a 33-month period.This regazification terminal project,including two full containment LNGtanks of 160,000 m 3 each, will bebuilt on reclaimed land from the sea.

<strong>CONSTRUCTION</strong>LNG DepartmentFirst floor, Al Omran Tower, T.C.A.P.O. Box 32369Abu DhabiUnited Arab EmiratesTel: +971 2 676 4401Fax: +971 2 676 4402E-mail: lng@vinci-construction.comHead Office5, cours Ferdinand-de-Lesseps92851 Rueil-Malmaison CedexFranceTel: +33 1 47 16 30 41Fax: +33 1 47 16 32 49www.vinci-construction.com/projets11/2005 - 1,000 copies - Photos: photo libraries of <strong>VINCI</strong> and subsidiaries.