Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

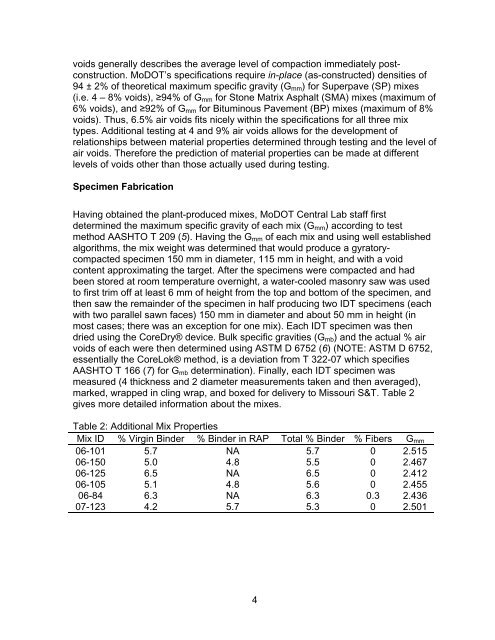

voids generally describes the average level <strong>of</strong> compaction immediately postconstruction.MoDOT’s specifications require in-place (as-constructed) densities <strong>of</strong>94 ± 2% <strong>of</strong> theoretical maximum specific gravity (G mm ) for Superpave (SP) mixes(i.e. 4 – 8% voids), ≥94% <strong>of</strong> G mm for Stone Matrix Asphalt (SMA) mixes (maximum <strong>of</strong>6% voids), <strong>and</strong> ≥92% <strong>of</strong> G mm for Bituminous Pavement (BP) mixes (maximum <strong>of</strong> 8%voids). Thus, 6.5% air voids fits nicely within the specifications for all three mixtypes. Additional testing at 4 <strong>and</strong> 9% air voids allows for the development <strong>of</strong>relationships between material properties determined through testing <strong>and</strong> the level <strong>of</strong>air voids. Therefore the prediction <strong>of</strong> material properties can be made at differentlevels <strong>of</strong> voids other than those actually used during testing.Specimen FabricationHaving obtained the plant-produced mixes, MoDOT Central Lab staff firstdetermined the maximum specific gravity <strong>of</strong> each mix (G mm ) according to testmethod AASHTO T 209 (5). Having the G mm <strong>of</strong> each mix <strong>and</strong> using well establishedalgorithms, the mix weight was determined that would produce a gyratorycompactedspecimen 150 mm in diameter, 115 mm in height, <strong>and</strong> with a voidcontent approximating the target. After the specimens were compacted <strong>and</strong> hadbeen stored at room temperature overnight, a water-cooled masonry saw was usedto first trim <strong>of</strong>f at least 6 mm <strong>of</strong> height from the top <strong>and</strong> bottom <strong>of</strong> the specimen, <strong>and</strong>then saw the remainder <strong>of</strong> the specimen in half producing two IDT specimens (eachwith two parallel sawn faces) 150 mm in diameter <strong>and</strong> about 50 mm in height (inmost cases; there was an exception for one mix). Each IDT specimen was thendried using the CoreDry® device. Bulk specific gravities (G mb ) <strong>and</strong> the actual % airvoids <strong>of</strong> each were then determined using ASTM D 6752 (6) (NOTE: ASTM D 6752,essentially the CoreLok® method, is a deviation from T 322-07 which specifiesAASHTO T 166 (7) for G mb determination). Finally, each IDT specimen wasmeasured (4 thickness <strong>and</strong> 2 diameter measurements taken <strong>and</strong> then averaged),marked, wrapped in cling wrap, <strong>and</strong> boxed for delivery to Missouri S&T. Table 2gives more detailed information about the mixes.Table 2: Additional <strong>Mix</strong> Properties<strong>Mix</strong> ID % Virgin Binder % Binder in RAP Total % Binder % Fibers G mm06-101 5.7 NA 5.7 0 2.51506-150 5.0 4.8 5.5 0 2.46706-125 6.5 NA 6.5 0 2.41206-105 5.1 4.8 5.6 0 2.45506-84 6.3 NA 6.3 0.3 2.43607-123 4.2 5.7 5.3 0 2.5014