Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

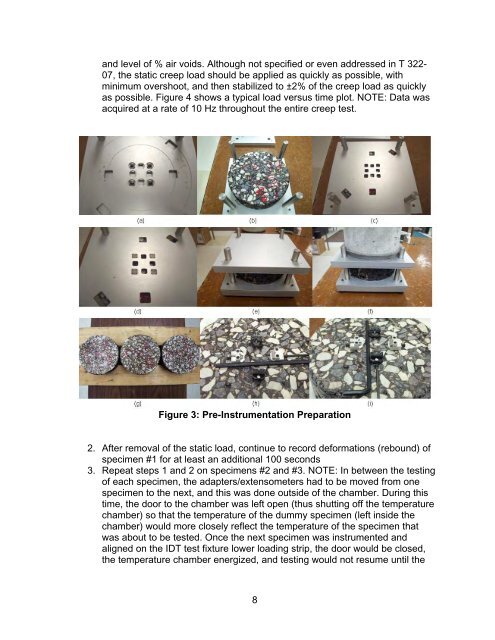

<strong>and</strong> level <strong>of</strong> % air voids. Although not specified or even addressed in T 322-07, the static creep load should be applied as quickly as possible, withminimum overshoot, <strong>and</strong> then stabilized to ±2% <strong>of</strong> the creep load as quicklyas possible. Figure 4 shows a typical load versus time plot. NOTE: Data wasacquired at a rate <strong>of</strong> 10 Hz throughout the entire creep test.Figure 3: Pre-Instrumentation Preparation2. After removal <strong>of</strong> the static load, continue to record deformations (rebound) <strong>of</strong>specimen #1 for at least an additional 100 seconds3. Repeat steps 1 <strong>and</strong> 2 on specimens #2 <strong>and</strong> #3. NOTE: In between the testing<strong>of</strong> each specimen, the adapters/extensometers had to be moved from onespecimen to the next, <strong>and</strong> this was done outside <strong>of</strong> the chamber. During thistime, the door to the chamber was left open (thus shutting <strong>of</strong>f the temperaturechamber) so that the temperature <strong>of</strong> the dummy specimen (left inside thechamber) would more closely reflect the temperature <strong>of</strong> the specimen thatwas about to be tested. Once the next specimen was instrumented <strong>and</strong>aligned on the IDT test fixture lower loading strip, the door would be closed,the temperature chamber energized, <strong>and</strong> testing would not resume until the8