Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

Determination of Creep Compliance and Tensile Strength of Hot-Mix ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

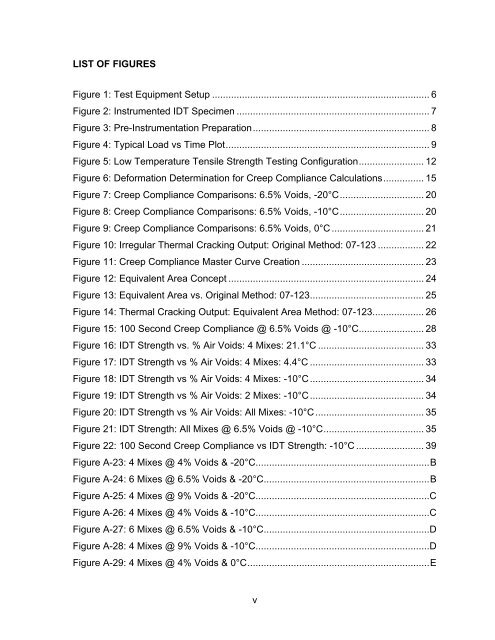

LIST OF FIGURESFigure 1: Test Equipment Setup ................................................................................ 6Figure 2: Instrumented IDT Specimen ....................................................................... 7Figure 3: Pre-Instrumentation Preparation................................................................. 8Figure 4: Typical Load vs Time Plot........................................................................... 9Figure 5: Low Temperature <strong>Tensile</strong> <strong>Strength</strong> Testing Configuration........................ 12Figure 6: Deformation <strong>Determination</strong> for <strong>Creep</strong> <strong>Compliance</strong> Calculations............... 15Figure 7: <strong>Creep</strong> <strong>Compliance</strong> Comparisons: 6.5% Voids, -20°C............................... 20Figure 8: <strong>Creep</strong> <strong>Compliance</strong> Comparisons: 6.5% Voids, -10°C............................... 20Figure 9: <strong>Creep</strong> <strong>Compliance</strong> Comparisons: 6.5% Voids, 0°C .................................. 21Figure 10: Irregular Thermal Cracking Output: Original Method: 07-123 ................. 22Figure 11: <strong>Creep</strong> <strong>Compliance</strong> Master Curve Creation ............................................. 23Figure 12: Equivalent Area Concept ........................................................................ 24Figure 13: Equivalent Area vs. Original Method: 07-123.......................................... 25Figure 14: Thermal Cracking Output: Equivalent Area Method: 07-123................... 26Figure 15: 100 Second <strong>Creep</strong> <strong>Compliance</strong> @ 6.5% Voids @ -10°C........................ 28Figure 16: IDT <strong>Strength</strong> vs. % Air Voids: 4 <strong>Mix</strong>es: 21.1°C ....................................... 33Figure 17: IDT <strong>Strength</strong> vs % Air Voids: 4 <strong>Mix</strong>es: 4.4°C .......................................... 33Figure 18: IDT <strong>Strength</strong> vs % Air Voids: 4 <strong>Mix</strong>es: -10°C.......................................... 34Figure 19: IDT <strong>Strength</strong> vs % Air Voids: 2 <strong>Mix</strong>es: -10°C.......................................... 34Figure 20: IDT <strong>Strength</strong> vs % Air Voids: All <strong>Mix</strong>es: -10°C........................................ 35Figure 21: IDT <strong>Strength</strong>: All <strong>Mix</strong>es @ 6.5% Voids @ -10°C..................................... 35Figure 22: 100 Second <strong>Creep</strong> <strong>Compliance</strong> vs IDT <strong>Strength</strong>: -10°C ......................... 39Figure A-23: 4 <strong>Mix</strong>es @ 4% Voids & -20°C................................................................BFigure A-24: 6 <strong>Mix</strong>es @ 6.5% Voids & -20°C.............................................................BFigure A-25: 4 <strong>Mix</strong>es @ 9% Voids & -20°C................................................................CFigure A-26: 4 <strong>Mix</strong>es @ 4% Voids & -10°C................................................................CFigure A-27: 6 <strong>Mix</strong>es @ 6.5% Voids & -10°C.............................................................DFigure A-28: 4 <strong>Mix</strong>es @ 9% Voids & -10°C................................................................DFigure A-29: 4 <strong>Mix</strong>es @ 4% Voids & 0°C...................................................................Ev