P1V-M Robust Air Motors - Duncan Rogers

P1V-M Robust Air Motors - Duncan Rogers

P1V-M Robust Air Motors - Duncan Rogers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

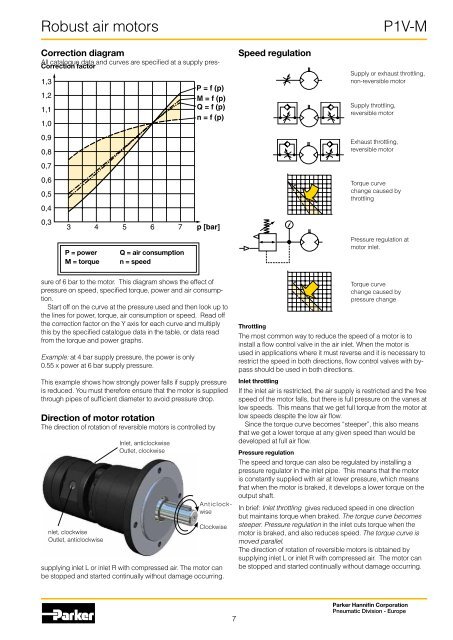

<strong>Robust</strong> air motorsCorrection diagram1,31,21,11,00,90,80,70,60,50,40,33 4 5 6 7P = powerM = torqueQ = air consumptionn = speedP = f (p)M = f (p)Q = f (p)n = f (p)p [bar]Speed regulationM<strong>P1V</strong>-MSupply or exhaust throttling,non-reversible motorSupply throttling,reversible motorExhaust throttling,reversible motorTorque curvechange caused bythrottlingPressure regulation atmotor inlet.All catalogue data and curves are specified at a supply pres-Correction factorsure of 6 bar to the motor. This diagram shows the effect ofpressure on speed, specified torque, power and air consumption.Start off on the curve at the pressure used and then look up tothe lines for power, torque, air consumption or speed. Read offthe correction factor on the Y axis for each curve and multiplythis by the specified catalogue data in the table, or data readfrom the torque and power graphs.Example: at 4 bar supply pressure, the power is only0.55 x power at 6 bar supply pressure.This example shows how strongly power falls if supply pressureis reduced. You must therefore ensure that the motor is suppliedthrough pipes of sufficient diameter to avoid pressure drop.Direction of motor rotationThe direction of rotation of reversible motors is controlled bynlet, clockwiseOutlet, anticlockwiseInlet, anticlockwiseOutlet, clockwiseAnticlockwiseClockwisesupplying inlet L or inlet R with compressed air. The motor canbe stopped and started continually without damage occurring.MTorque curvechange caused bypressure changeThrottlingThe most common way to reduce the speed of a motor is toinstall a flow control valve in the air inlet. When the motor isused in applications where it must reverse and it is necessary torestrict the speed in both directions, flow control valves with bypassshould be used in both directions.Inlet throttlingIf the inlet air is restricted, the air supply is restricted and the freespeed of the motor falls, but there is full pressure on the vanes atlow speeds. This means that we get full torque from the motor atlow speeds despite the low air flow.Since the torque curve becomes “steeper”, this also meansthat we get a lower torque at any given speed than would bedeveloped at full air flow.Pressure regulationThe speed and torque can also be regulated by installing apressure regulator in the inlet pipe. This means that the motoris constantly supplied with air at lower pressure, which meansthat when the motor is braked, it develops a lower torque on theoutput shaft.In brief: Inlet throttling gives reduced speed in one directionbut maintains torque when braked. The torque curve becomessteeper. Pressure regulation in the inlet cuts torque when themotor is braked, and also reduces speed. The torque curve ismoved parallel.The direction of rotation of reversible motors is obtained bysupplying inlet L or inlet R with compressed air. The motor canbe stopped and started continually without damage occurring.7Parker Hannifin CorporationPneumatic Division - Europe