MP 1, SQE-NE, SPA-NE, SP-NE - SCL Water

MP 1, SQE-NE, SPA-NE, SP-NE - SCL Water

MP 1, SQE-NE, SPA-NE, SP-NE - SCL Water

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

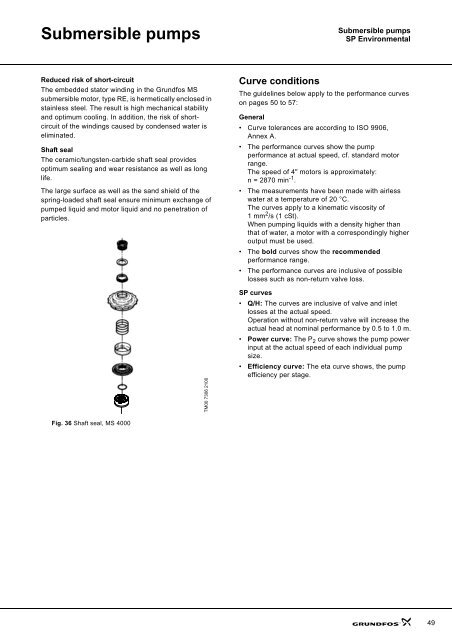

Submersible pumpsSubmersible pumps<strong>SP</strong> EnvironmentalReduced risk of short-circuitThe embedded stator winding in the Grundfos MSsubmersible motor, type RE, is hermetically enclosed instainless steel. The result is high mechanical stabilityand optimum cooling. In addition, the risk of shortcircuitof the windings caused by condensed water iseliminated.Shaft sealThe ceramic/tungsten-carbide shaft seal providesoptimum sealing and wear resistance as well as longlife.The large surface as well as the sand shield of thespring-loaded shaft seal ensure minimum exchange ofpumped liquid and motor liquid and no penetration ofparticles.TM00 7306 2100Curve conditionsThe guidelines below apply to the performance curveson pages 50 to 57:General• Curve tolerances are according to ISO 9906,Annex A.• The performance curves show the pumpperformance at actual speed, cf. standard motorrange.The speed of 4" motors is approximately:n = 2870 min -1 .• The measurements have been made with airlesswater at a temperature of 20 °C.The curves apply to a kinematic viscosity of1mm 2 /s (1 cSt).When pumping liquids with a density higher thanthat of water, a motor with a correspondingly higheroutput must be used.• The bold curves show the recommendedperformance range.• The performance curves are inclusive of possiblelosses such as non-return valve loss.<strong>SP</strong> curves• Q/H: The curves are inclusive of valve and inletlosses at the actual speed.Operation without non-return valve will increase theactual head at nominal performance by 0.5 to 1.0 m.• Power curve: The P 2 curve shows the pump powerinput at the actual speed of each individual pumpsize.• Efficiency curve: The eta curve shows, the pumpefficiency per stage.Fig. 36 Shaft seal, MS 400049