STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

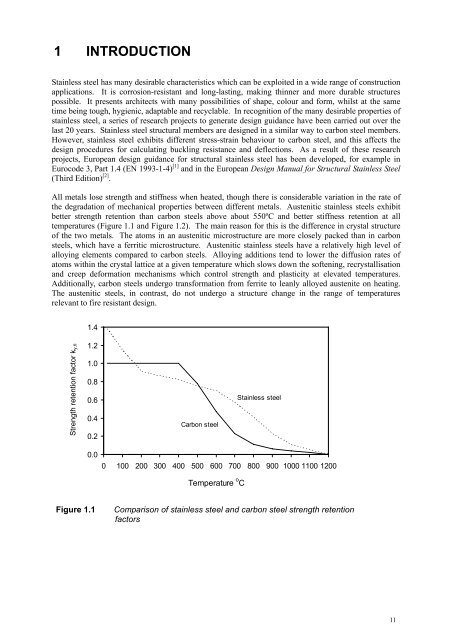

1 <strong>IN</strong>TRODUCTIONStainless steel has many desirable characteristics which can be exploited in a wide range of constructionapplications. It is corrosion-resistant and long-lasting, making thinner and more durable structurespossible. It presents architects with many possibilities of shape, colour and form, whilst at the sametime being tough, hygienic, adaptable and recyclable. In recognition of the many desirable properties of<strong>stainless</strong> steel, a series of research projects to generate design guidance have been carried out over thelast 20 years. Stainless steel structural members are designed in a similar way to carbon steel members.However, <strong>stainless</strong> steel exhibits different stress-strain behaviour to carbon steel, and this affects thedesign procedures for calculating buckling resistance and deflections. As a result of these researchprojects, European design guidance for structural <strong>stainless</strong> steel has been developed, for example inEurocode 3, Part 1.4 (EN 1993-1-4) [1] and in the European Design Manual for Structural Stainless <strong>Steel</strong>(Third Edition) [2] .All metals lose strength and stiffness when heated, though there is considerable variation in the rate ofthe degradation of mechanical properties between different metals. Austenitic <strong>stainless</strong> steels exhibitbetter strength retention than carbon steels above about 550ºC and better stiffness retention at alltemperatures (Figure 1.1 and Figure 1.2). The main reason for this is the difference in crystal structureof the two metals. The atoms in an austenitic microstructure are more closely packed than in carbonsteels, which have a ferritic microstructure. Austenitic <strong>stainless</strong> steels have a relatively high level ofalloying elements compared to carbon steels. Alloying additions tend to lower the diffusion rates ofatoms within the crystal lattice at a given temperature which slows down the softening, recrystallisationand creep deformation mechanisms which control strength and plasticity at elevated temperatures.Additionally, carbon steels undergo transformation from ferrite to leanly alloyed austenite on heating.The austenitic steels, in contrast, do not undergo a structure change in the range of temperaturesrelevant to fire resistant design.1.4Strength fy( retention ) / fy(20 o factor C) ky,θ1.21.00.80.60.40.2Carbon steelStainless steel0.00 100 200 300 400 500 600 700 800 900 1000 1100 1200Temperature o CFigure 1.1Comparison of <strong>stainless</strong> steel and carbon steel strength retentionfactors11