STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

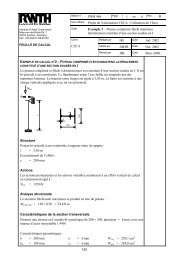

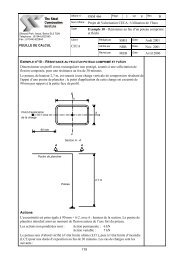

calculation of the neutral axis and corresponding moment resistance by taking into account thetemperature distribution through the cross-section and the corresponding reduction in material strength.To compare the performance of <strong>stainless</strong> and carbon steel composite beams, a numerical study wascarried out on different beam cross-sections. For the same fire rating, the bending moment resistance ofcarbon steel beams is always lower than the beam with the exposed lower flange from <strong>stainless</strong> steel.4. WP3: Class 4 cross sections in fireA programme of six fire tests on loaded RHS columns with slender (Class 4) cross-sections wasperformed. The length of the columns was 0.9 m. Numerical models were calibrated against testresults and then parametric studies carried out to develop more economic design guidance than iscurrently in existing guidance. The proposed model uses the room temperature buckling curve with theglobal, local and limiting slendernesses all being related to the temperature-dependent ratio of strengthto stiffness. The analysis of 3.1 m long pinned columns in a standard fire shows that it is possible forunprotected Class 4 <strong>stainless</strong> steel columns to achieve 30 minutes fire resistance if the load level doesnot exceed 0.3.5. WP4: Properties at elevated temperaturesStrength retention curves for two grades of <strong>stainless</strong> not previously studied were derived through aprogramme of transient state tests. The grades studied were the stabilised austenitic grade 1.4541 andSTR18, a low nickel, high manganese and nitrogen austenitic steel with high strength. Using the testresults, strength and stiffness parameters were derived for use with the numerical model in EN 1993-1-2.6. WP5: Bolts and welds at elevated temperaturesSteady state (isothermal) tests were carried out on butt welded joints in grades 1.4318 and 1.4571austenitic <strong>stainless</strong> steel. The strength retention factors for the butt welded joints for both the <strong>stainless</strong>steel grades were compared to factors for the base material given in the Design Manual for StructuralStainless <strong>Steel</strong>. It was concluded from the test results that the design strength of a full penetration buttweld, for temperatures up to 1000°C, could be taken as equal to the strength of the base material f<strong>org</strong>rades 1.4318 and 1.4571 in the annealed condition.Over forty isothermal tests from room temperature up to 900°C were performed on bolt assemblies intension and shear; two grades of bolt were tested, A2-70 and A4-80. The tests showed that <strong>stainless</strong>steel bolts act better than carbon steel bolts at high temperatures beyond 400 to 450°C. Grade A4-80bolts performed slightly better than grade A2-70. Based on the test results, strength retention factorswere derived for <strong>stainless</strong> steel bolts.7. WP6: Parametric fire designThe behaviour of external <strong>stainless</strong> steel columns and <strong>stainless</strong> steel columns in open car parks subjectto realistic fire loads was studied numerically. The temperature distribution in <strong>stainless</strong> steel columnslocated outside a building on fire was studied and the performance was compared to equivalent columnsfrom carbon steel grade S235. For the scenarios studied with a load level of 0.3, carbon steel columnsfailed after less than 30 minutes fire exposure, whereas the <strong>stainless</strong> steel columns remained stablethroughout the whole fire duration. A simplified design approach was developed for external <strong>stainless</strong>steel columns.The behaviour of <strong>stainless</strong> steel columns in open car parks of steel and concrete composite constructionwas studied using a fire safety engineering procedure developed in France and validated againstexperimental results. Numerical investigations enabled the maximum load level for unprotected<strong>stainless</strong> steel hollow columns to be determined.8