STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

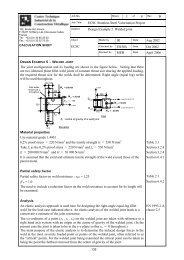

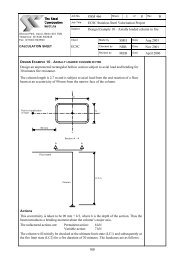

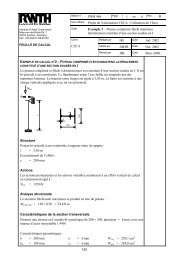

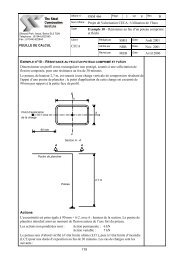

ForceFGage 3Gage 2Gage 4Gage 1Deflection 6Deflection 5Figure 5.1Test arrangementTable 5.2Test results at room temperatureProfileFailure load (kN)RHS 200 × 200 × 5 1129RHS 200 × 200 × 5 1118RHS 150 × 150 × 3 398RHS 150 × 150 × 3 393Tests at elevated temperaturesSix unprotected columns were loaded concentrically at elevated temperatures. The columns were RHSwith the same cross-sectional dimensions (200x200x5 and 150x150x3) and length as the roomtemperature tests. The test set-up was also equivalent. The columns were fixed at both ends.The steel columns were heated in a model furnace consisting of a furnace chamber located within asteel framework. The chamber was 1500 mm wide, 1300 mm high and 1500 mm deep. It was linedwith fire resistant bricks and it had four oil burners inside, two in each of the two walls. The transientstate test procedure was applied, meaning that the axial load was kept constant and the furnacetemperature was raised in a controlled way, at the rate of 10°C/min. The columns were tested at threedifferent load levels.The load was applied with a hydraulic jack of 2MN capacity located above the furnace chamber(Figure 5.2). Axial deformation of the specimen was determined by measuring the displacement of thetop of the water–cooled steel unit, using transducers. The load was controlled and measured usingpressure transducers.42