STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

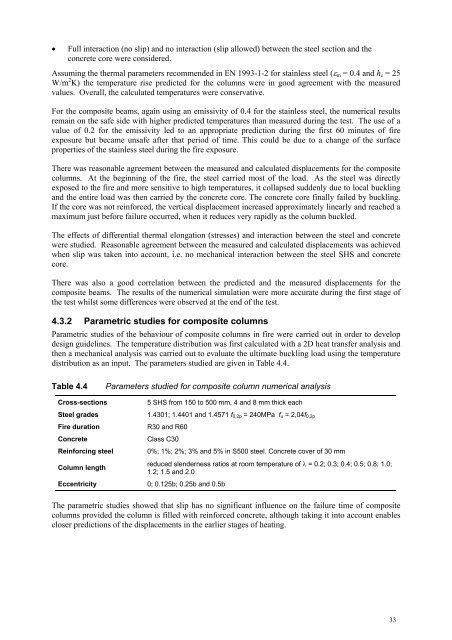

• Full interaction (no slip) and no interaction (slip allowed) between the steel section and theconcrete core were considered.Assuming the thermal parameters recommended in EN 1993-1-2 for <strong>stainless</strong> steel (ε m = 0.4 and h c = 25W/m 2 K) the temperature rise predicted for the columns were in good agreement with the measuredvalues. Overall, the calculated temperatures were conservative.For the composite beams, again using an emissivity of 0.4 for the <strong>stainless</strong> steel, the numerical resultsremain on the safe side with higher predicted temperatures than measured during the test. The use of avalue of 0.2 for the emissivity led to an appropriate prediction during the first 60 minutes of fireexposure but became unsafe after that period of time. This could be due to a change of the surfaceproperties of the <strong>stainless</strong> steel during the fire exposure.There was reasonable agreement between the measured and calculated displacements for the compositecolumns. At the beginning of the fire, the steel carried most of the load. As the steel was directlyexposed to the fire and more sensitive to high temperatures, it collapsed suddenly due to local bucklingand the entire load was then carried by the concrete core. The concrete core finally failed by buckling.If the core was not reinforced, the vertical displacement increased approximately linearly and reached amaximum just before failure occurred, when it reduces very rapidly as the column buckled.The effects of differential thermal elongation (stresses) and interaction between the steel and concretewere studied. Reasonable agreement between the measured and calculated displacements was achievedwhen slip was taken into account, i.e. no mechanical interaction between the steel SHS and concretecore.There was also a good correlation between the predicted and the measured displacements for thecomposite beams. The results of the numerical simulation were more accurate during the first stage ofthe test whilst some differences were observed at the end of the test.4.3.2 Parametric studies for composite columnsParametric studies of the behaviour of composite columns in fire were carried out in order to developdesign guidelines. The temperature distribution was first calculated with a 2D heat transfer analysis andthen a mechanical analysis was carried out to evaluate the ultimate buckling load using the temperaturedistribution as an input. The parameters studied are given in Table 4.4.Table 4.4Parameters studied for composite column numerical analysisCross-sections5 SHS from 150 to 500 mm, 4 and 8 mm thick each<strong>Steel</strong> grades 1.4301; 1.4401 and 1.4571 f 0,2p = 240MPa f u = 2,04f 0,2pFire durationR30 and R60ConcreteClass C30Reinforcing steel 0%; 1%; 2%; 3% and 5% in S500 steel. Concrete cover of 30 mmColumn lengthreduced slenderness ratios at room temperature of λ = 0.2; 0.3; 0.4; 0.5; 0.8; 1.0;1.2; 1.5 and 2.0Eccentricity 0; 0.125b; 0.25b and 0.5bThe parametric studies showed that slip has no significant influence on the failure time of compositecolumns provided the column is filled with reinforced concrete, although taking it into account enablescloser predictions of the displacements in the earlier stages of heating.33