STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

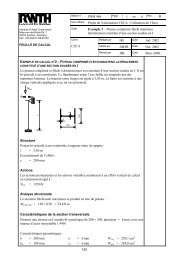

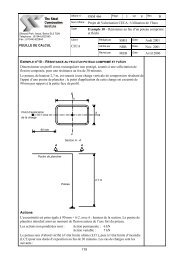

Although a very good estimate of the maximum temperatures can be obtained for the unexposed side,the temperatures midway between the profiles are overestimated due to the inaccuracy of the mineralwool data and the idealisation of full continuity between surfaces, which leads to a higher temperaturefrom the numerical analysis.In order to satisfy the insulation criteria given in EN 1363-1 (average temperature not greater than140°C and a temperature increase with respect to the initial of no more than 180°C) parametric studieswere carried out in order to determine the depth of the wall which could achieve 60 minutes fireresistance. The parameter varied was the height of the Z profile and thickness of the insulation from60 mm to 80, 100 and 120 mm. Figure 3.13 shows the results for the unexposed face of the flange ofthe Z-section. For each wall thickness, two curves are shown corresponding to different insulationdensities giving upper and lower bounds for the temperatures reached at the unexposed face. Assumingthat the actual temperature rise is the average of the temperature increases obtained for the two mineralwool densities, it was concluded that only the 120 mm thick wall was sufficient to satisfy the criteria.The 100 mm thick wall might be sufficient provided the mineral wool density approximated to 140kg/m 3 .Unexposed side temperatures in wall test (at webs)Temperature (oC)4003503002502001501005000 10 20 30 40 50 60Time (min)60 mm Unexp at webwool30 h = 1060 mm Unexp at webwool140 h = 1080 mm Unexp at webwool3080 mm Unexp at webwool140100 mm Unexp atweb wool30100 mm Unexp atweb wool140120 mm Unexp atweb wool30120 mm Unexp atweb wool140Figure 3.13Calculated temperatures at the unexposed face of the flange of the Z-profilewith heights 60 mm (black), 80 mm (green), 100 mm (red) and 120 mm (blue)and different insulation densities.Floor elementIn order to determine the load displacement curve of the floor element subject to the standard fire curve,a thermal analysis was first carried out. The thermal analysis was performed as a two-dimensionalfinite element analysis using ABAQUS. Direct heat transfer was assumed between <strong>stainless</strong> steel andthe insulation material. The thermal action was applied according to the standard temperature-timecurve. The coefficient of heat transfer due to convection was applied according to EN 1991-1-2 [9] . Thesurface emissivity of the member was taken as 0.2 (fire exposed side). To reduce the size of the model,only half the rib was modelled. The geometry, mesh and boundary conditions are illustrated inFigure 3.1425