STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

STAINLESS STEEL IN FIRE (SSIF) - Steel-stainless.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

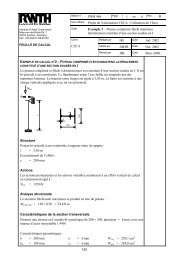

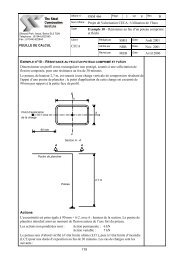

ϕ a,θ and ϕ c,θare reduction coefficients due to the differential effects of thermal stresses.ϕ a,θ depends on the fire rating only and ϕ c,θ is defined by six parameters depending on the cross-sectionsize, column buckling length, reinforcing ratio and fire rating. ϕ c,θ ranges from 0 to 1; when it is 0 thefire resistance of the column is provided by the hollow section only, and when it is 1, the column acts asa composite element with significant interaction between steel and concrete.Appendix A gives the reduction coefficients ϕ a,θ and ϕ c,θ and the Final Work Package Report gives acomplete set of expressions for the buckling resistance under eccentric loading.Comparisons between the proposed design method and the numerical model show that in the majorityof cases, the proposed design method is conservative. A comparison between the proposed designmethod and fire test results show that the difference does not exceed 15%. Moreover, the unsafe resultscorrespond to columns which failed after 60 minutes, the maximum fire rating for which the proposeddesign method is valid. For the tests in the range of application of the proposed method, all thepredictions were conservative.4.3.4 Parametric studies for composite beams2D thermal analyses were carried out to establish simplified temperature distributions for exposure tothe standard fire curve for 120 minutes for eight integrated floor beams (IF beam no. 1 in Figure 4.3)and seven slim floor beams (SF beam no. 2 in Figure 4.3). Figure 4.5 shows the results for the IFbeams. In all cases there is a large temperature gradient in the cross section due to the encasement ofconcrete. After 30 minutes, the carbon steel remains below 400°C (full strength). After 60 minutes, upto 25% of the depth of the web is above 400°C. After 120 minutes, about 50% of the carbon steelsection is above 400°C. The unexposed side remains at a temperature lower than 100°C after 120minutes of fire exposure. This means that the insulation criterion is always satisfied with this type ofstructural member.<strong>Steel</strong> temperature (°C)10009008007006001/2 IPE400-380x10 1/2 IPE400-380x10 1/2 IPE400-380x101/2 IPE400-380x10 1/2 HEB300-500x15 1/2 HEB300-500x151/2 HEB300-500x15 1/2 HEB300-500x15 1/2 IPE500-400x121/2 IPE500-400x12 1/2 IPE500-400x12 1/2 IPE500-400x121/2 HE500-500x20 1/2 HE500-500x20 1/2 HE500-500x201/2 HEB600 500x20 1/2 HEB600 500x20 1/2 HEB600 500x201/2 HEB600 500x20 1/2 HEB600 500x20 1/2 HEA450 500x151/2 HEA450 500x15 1/2 HEA450 500x15 1/2 HEA450 500x15500400300200100R60R30R120R900-25 0 25 50 75 100 125 150 175 200 225 250 275 300Depth on the beam (mm)Stainless steelplateCarbon steel profileFigure 4.5 Temperature distribution along the depth of IF beams from 30 to 120minutes of standard fire exposure35