GM 3000AC - WAGNER-Group

GM 3000AC - WAGNER-Group

GM 3000AC - WAGNER-Group

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

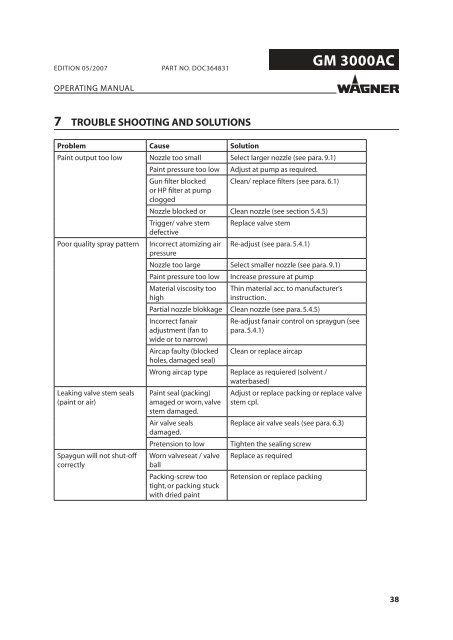

EDITION 05/2007OPERATING MANUALPART NO. DOC364831<strong>GM</strong> <strong>3000AC</strong>7 TROUBLE SHOOTING AND SOLUTIONSProblem Cause SolutionPaint output too low Nozzle too small Select larger nozzle (see para. 9.1)Poor quality spray patternLeaking valve stem seals(paint or air)Spaygun will not shut-offcorrectlyPaint pressure too low Adjust at pump as required.Gun filter blocked Clean/ replace filters (see para. 6.1)or HP filter at pumpcloggedNozzle blocked or Clean nozzle (see section 5.4.5)Trigger/ valve stem Replace valve stemdefectiveIncorrect atomizing air Re-adjust (see para. 5.4.1)pressureNozzle too large Select smaller nozzle (see para. 9.1)Paint pressure too low Increase pressure at pumpMaterial viscosity toohighThin material acc. to manufacturer‘sinstruction.Partial nozzle blokkage Clean nozzle (see para. 5.4.5)Incorrect fanairadjustment (fan towide or to narrow)Aircap faulty (blockedholes, damaged seal)Re-adjust fanair control on spraygun (seepara. 5.4.1)Clean or replace aircapWrong aircap type Replace as requiered (solvent /waterbased)Paint seal (packing)amaged or worn, valvestem damaged.Air valve sealsdamaged.Pretension to lowWorn valveseat / valveballPacking-screw tootight, or packing stuckwith dried paintAdjust or replace packing or replace valvestem cpl.Replace air valve seals (see para. 6.3)Tighten the sealing screwReplace as requiredRetension or replace packing38