Autotrol Performa Valve - Pentair Residential Filtration

Autotrol Performa Valve - Pentair Residential Filtration

Autotrol Performa Valve - Pentair Residential Filtration

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

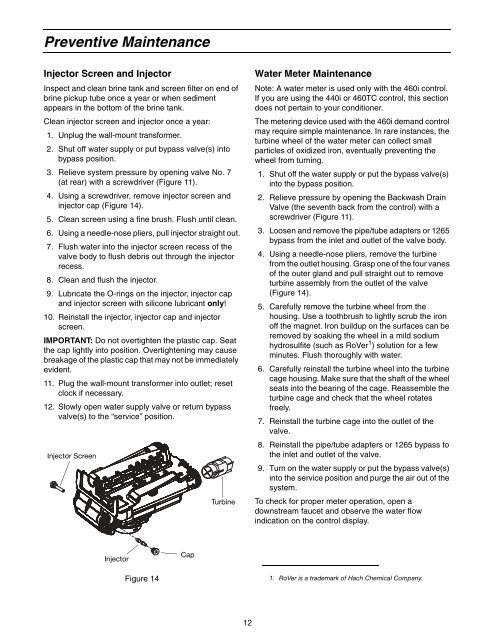

Preventive MaintenanceInjector Screen and InjectorInspect and clean brine tank and screen filter on end ofbrine pickup tube once a year or when sedimentappears in the bottom of the brine tank.Clean injector screen and injector once a year:1. Unplug the wall-mount transformer.2. Shut off water supply or put bypass valve(s) intobypass position.3. Relieve system pressure by opening valve No. 7(at rear) with a screwdriver (Figure 11).4. Using a screwdriver, remove injector screen andinjector cap (Figure 14).5. Clean screen using a fine brush. Flush until clean.6. Using a needle-nose pliers, pull injector straight out.7. Flush water into the injector screen recess of thevalve body to flush debris out through the injectorrecess.8. Clean and flush the injector.9. Lubricate the O-rings on the injector, injector capand injector screen with silicone lubricant only!10. Reinstall the injector, injector cap and injectorscreen.IMPORTANT: Do not overtighten the plastic cap. Seatthe cap lightly into position. Overtightening may causebreakage of the plastic cap that may not be immediatelyevident.11. Plug the wall-mount transformer into outlet; resetclock if necessary.12. Slowly open water supply valve or return bypassvalve(s) to the “service” position.Injector ScreenTurbineWater Meter MaintenanceNote: A water meter is used only with the 460i control.If you are using the 440i or 460TC control, this sectiondoes not pertain to your conditioner.The metering device used with the 460i demand controlmay require simple maintenance. In rare instances, theturbine wheel of the water meter can collect smallparticles of oxidized iron, eventually preventing thewheel from turning.1. Shut off the water supply or put the bypass valve(s)into the bypass position.2. Relieve pressure by opening the Backwash Drain<strong>Valve</strong> (the seventh back from the control) with ascrewdriver (Figure 11).3. Loosen and remove the pipe/tube adapters or 1265bypass from the inlet and outlet of the valve body.4. Using a needle-nose pliers, remove the turbinefrom the outlet housing. Grasp one of the four vanesof the outer gland and pull straight out to removeturbine assembly from the outlet of the valve(Figure 14).5. Carefully remove the turbine wheel from thehousing. Use a toothbrush to lightly scrub the ironoff the magnet. Iron buildup on the surfaces can beremoved by soaking the wheel in a mild sodiumhydrosulfite (such as RoVer 1 ) solution for a fewminutes. Flush thoroughly with water.6. Carefully reinstall the turbine wheel into the turbinecage housing. Make sure that the shaft of the wheelseats into the bearing of the cage. Reassemble theturbine cage and check that the wheel rotatesfreely.7. Reinstall the turbine cage into the outlet of thevalve.8. Reinstall the pipe/tube adapters or 1265 bypass tothe inlet and outlet of the valve.9. Turn on the water supply or put the bypass valve(s)into the service position and purge the air out of thesystem.To check for proper meter operation, open adownstream faucet and observe the water flowindication on the control display.InjectorCapFigure 141. RoVer is a trademark of Hach Chemical Company.12