Safety Standard Certified Ceramic Capacitors/High Voltage ... - Murata

Safety Standard Certified Ceramic Capacitors/High Voltage ... - Murata

Safety Standard Certified Ceramic Capacitors/High Voltage ... - Murata

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

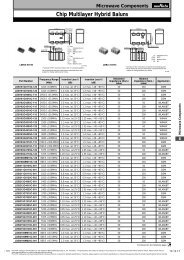

!Note • Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.• This catalog has only typical specifications. Therefore, please approve our product specifi cations or transact the approval sheet for product specifi cations before ordering.C85E.pdfApr.7,2014DEJ Series Specifications and Test MethodsContinued from the preceding page.No.ItemSpecificationsTest MethodAppearanceNo marked defect16 HumidityLoadingCapacitanceChangeD.F.I.R.Char.EFChar.EF1000MΩ min.Capacitance ChangeWithin ±20%Within ±30%SpecificationsD.F.V5.0%D.F.V7.5%Apply the rated voltage for 500±12 hrs. at 40±2°C in 90 to 95%relative humidity.Pre-treatment:Capacitor should be stored at 85±2°C for 1 hr., then placed atroom condition* 1 for 24±2 hrs. before initial measurements.Post-treatment:Capacitor should be stored for 1 to 2 hrs. at room condition.* 1DielectricStrengthPer Item 6517 LifeAppearanceCapacitanceChangeI.R.DielectricStrengthNo marked defectChar.EF1000MΩ min.Per Item 6Capacitance ChangeWithin ±20%Within ±30%Apply a voltage from Table 2 for 1500 hrs. at 85±2°C, relativehumidity 50% max.Applied <strong>Voltage</strong>AC500V(r.m.s.), except that once each hour the voltageis increased to AC1000V(r.m.s.) for 0.1 sec.Pre-treatment:Capacitor should be stored at 85±2°C for 1 hr., then placed atroom condition* 1 for 24±2 hrs. before initial measurements.Post-treatment:Capacitor should be stored for 4 to 24 hrs. at room condition.* 118 Flame TestThe capacitor flame discontinued as follows.Cycle1 to 23Time (sec.)15 max.60 max.The capacitor should be subjectedto applied flame for 15 sec. and thenremoved for 15 sec. until 3 cyclesare completed.Gas Burner: Inside Dia. 9.520°7638CapacitorFlame127(in mm)1920RobustnessofTerminationsTemperatureandImmersionCycleTensileBendingAppearanceCapacitanceChangeD.F.I.R.DielectricStrengthLead wire should not be cut off. Capacitor shouldnot be broken.No marked defectChar.EFChar.EF1000MΩ min.Per Item 6Capacitance ChangeWithin ±20%Within ±30%SpecificationsD.F.V5.0%D.F.V7.5%Step1234* 1 "Room condition" Temperature: 15 to 35°C, Relative humidity: 45 to 75%, Atmospheric pressure: 86 to 106kPaAs shown in the figure at right, fix the body of thecapacitor, apply a tensile weight gradually toeach lead wire in the radial direction of thecapacitor up to 10N and keep it for 10±1 sec.Each lead wire should be subjected to 5N of weight and bent90° at the point of egress, in one direction, then returned to itsoriginal position and bent 90° in the opposite direction at therate of one bend in 2 to 3 sec.The capacitor should be subjected to 5 temperature cycles,then consecutively to 2 immersion cycles.Step12Temperature (ºC)-25+0/-3Room temp.85+3/-0Room temp.TimeTemperature (ºC)(min)65+5/-00±31515Time (min)303303Cycle time: 5 cyclesImmersionWaterCleanwaterSaltwaterCycle time: 2 cyclesPre-treatment:Capacitor should be stored at 85±2˚C for 1 hr., then placed atroom condition* 1 for 24±2 hrs.Post-treatment:Capacitor should be stored for 4 to 24 hrs. at room condition.* 1W22