Download LINK - Rieter

Download LINK - Rieter

Download LINK - Rieter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

26 <strong>LINK</strong> 58 . 2 /2011<br />

PARTS<br />

<strong>Rieter</strong> nippers<br />

<strong>Rieter</strong> combers have been developed to operate at high nip rates.<br />

Original spare parts from <strong>Rieter</strong> are essential to enable this advantage to<br />

be exploited throughout the machine’s life cycle. This is also true of the<br />

nippers. They feature the high precision of a Swiss watch movement and<br />

are as unique as a fingerprint.<br />

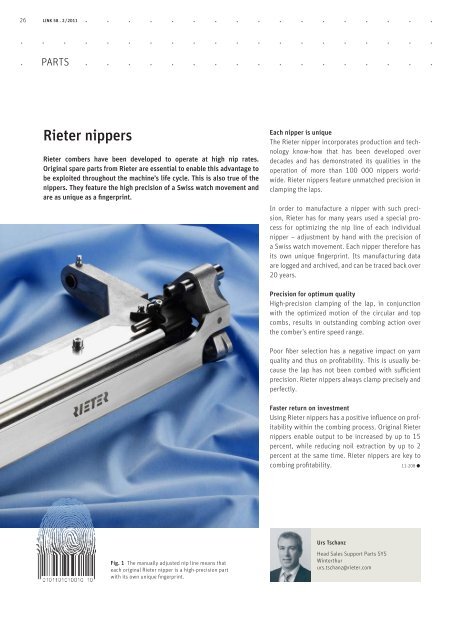

Fig. 1 The manually adjusted nip line means that<br />

each original <strong>Rieter</strong> nipper is a high-precision part<br />

with its own unique fingerprint.<br />

Each nipper is unique<br />

The <strong>Rieter</strong> nipper incorporates production and technology<br />

know-how that has been developed over<br />

decades and has demonstrated its qualities in the<br />

operation of more than 100 000 nippers worldwide.<br />

<strong>Rieter</strong> nippers feature unmatched precision in<br />

clamping the laps.<br />

In order to manufacture a nipper with such precision,<br />

<strong>Rieter</strong> has for many years used a special process<br />

for optimizing the nip line of each individual<br />

nipper – adjustment by hand with the precision of<br />

a Swiss watch movement. Each nipper therefore has<br />

its own unique fingerprint. Its manufacturing data<br />

are logged and archived, and can be traced back over<br />

20 years.<br />

Precision for optimum quality<br />

High-precision clamping of the lap, in conjunction<br />

with the optimized motion of the circular and top<br />

combs, results in outstanding combing action over<br />

the comber’s entire speed range.<br />

Poor fiber selection has a negative impact on yarn<br />

quality and thus on profitability. This is usually because<br />

the lap has not been combed with sufficient<br />

precision. <strong>Rieter</strong> nippers always clamp precisely and<br />

perfectly.<br />

Faster return on investment<br />

Using <strong>Rieter</strong> nippers has a positive influence on profitability<br />

within the combing process. Original <strong>Rieter</strong><br />

nippers enable output to be increased by up to 15<br />

percent, while reducing noil extraction by up to 2<br />

percent at the same time. <strong>Rieter</strong> nippers are key to<br />

combing profitability. 11-208 •<br />

Urs Tschanz<br />

Head Sales Support Parts SYS<br />

Winterthur<br />

urs.tschanz@rieter.com