F4E Annual Report 2009 - Fusion For Energy - Europa

F4E Annual Report 2009 - Fusion For Energy - Europa

F4E Annual Report 2009 - Fusion For Energy - Europa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

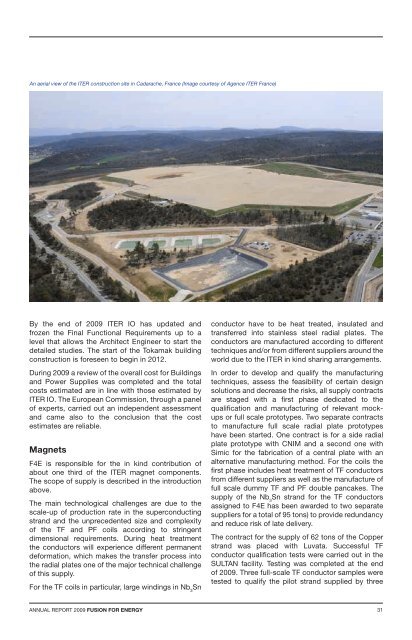

An aerial view of the ITER construction site in Cadarache, France (Image courtesy of Agence ITER France)By the end of <strong>2009</strong> ITER IO has updated andfrozen the Final Functional Requirements up to alevel that allows the Architect Engineer to start thedetailed studies. The start of the Tokamak buildingconstruction is foreseen to begin in 2012.During <strong>2009</strong> a review of the overall cost for Buildingsand Power Supplies was completed and the totalcosts estimated are in line with those estimated byITER IO. The European Commission, through a panelof experts, carried out an independent assessmentand came also to the conclusion that the costestimates are reliable.Magnets<strong>F4E</strong> is responsible for the in kind contribution ofabout one third of the ITER magnet components.The scope of supply is described in the introductionabove.The main technological challenges are due to thescale-up of production rate in the superconductingstrand and the unprecedented size and complexityof the TF and PF coils according to stringentdimensional requirements. During heat treatmentthe conductors will experience different permanentdeformation, which makes the transfer process intothe radial plates one of the major technical challengeof this supply.<strong>For</strong> the TF coils in particular, large windings in Nb 3Snconductor have to be heat treated, insulated andtransferred into stainless steel radial plates. Theconductors are manufactured according to differenttechniques and/or from different suppliers around theworld due to the ITER in kind sharing arrangements.In order to develop and qualify the manufacturingtechniques, assess the feasibility of certain designsolutions and decrease the risks, all supply contractsare staged with a first phase dedicated to thequalification and manufacturing of relevant mockupsor full scale prototypes. Two separate contractsto manufacture full scale radial plate prototypeshave been started. One contract is for a side radialplate prototype with CNIM and a second one withSimic for the fabrication of a central plate with analternative manufacturing method. <strong>For</strong> the coils thefirst phase includes heat treatment of TF conductorsfrom different suppliers as well as the manufacture offull scale dummy TF and PF double pancakes. Thesupply of the Nb 3Sn strand for the TF conductorsassigned to <strong>F4E</strong> has been awarded to two separatesuppliers for a total of 95 tons) to provide redundancyand reduce risk of late delivery.The contract for the supply of 62 tons of the Copperstrand was placed with Luvata. Successful TFconductor qualification tests were carried out in theSULTAN facility. Testing was completed at the endof <strong>2009</strong>. Three full-scale TF conductor samples weretested to qualify the pilot strand supplied by threeANNUAL REPORT <strong>2009</strong> FUSION FOR ENERGY31