Guidelines for Best Practice and Quality Checking of Ortho Imagery

Guidelines for Best Practice and Quality Checking of Ortho Imagery

Guidelines for Best Practice and Quality Checking of Ortho Imagery

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

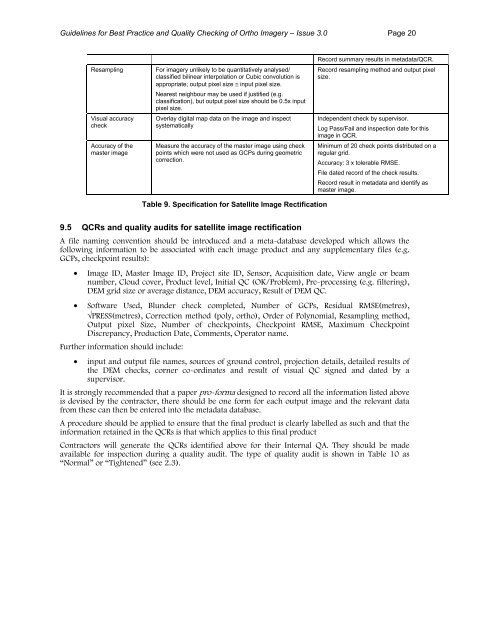

<strong>Guidelines</strong> <strong>for</strong> <strong>Best</strong> <strong>Practice</strong> <strong>and</strong> <strong>Quality</strong> <strong>Checking</strong> <strong>of</strong> <strong>Ortho</strong> <strong>Imagery</strong> – Issue 3.0 Page 20ResamplingVisual accuracycheckAccuracy <strong>of</strong> themaster imageFor imagery unlikely to be quantitatively analysed/classified bilinear interpolation or Cubic convolution isappropriate; output pixel size ≅ input pixel size.Nearest neighbour may be used if justified (e.g.classification), but output pixel size should be 0.5x inputpixel size.Overlay digital map data on the image <strong>and</strong> inspectsystematicallyMeasure the accuracy <strong>of</strong> the master image using checkpoints which were not used as GCPs during geometriccorrection.Record summary results in metadata/QCR.Record resampling method <strong>and</strong> output pixelsize.Independent check by supervisor.Log Pass/Fail <strong>and</strong> inspection date <strong>for</strong> thisimage in QCR.Minimum <strong>of</strong> 20 check points distributed on aregular grid.Accuracy: 3 x tolerable RMSE.File dated record <strong>of</strong> the check results.Record result in metadata <strong>and</strong> identify asmaster image.Table 9. Specification <strong>for</strong> Satellite Image Rectification9.5 QCRs <strong>and</strong> quality audits <strong>for</strong> satellite image rectificationA file naming convention should be introduced <strong>and</strong> a meta-database developed which allows thefollowing in<strong>for</strong>mation to be associated with each image product <strong>and</strong> any supplementary files (e.g.GCPs, checkpoint results):• Image ID, Master Image ID, Project site ID, Sensor, Acquisition date, View angle or beamnumber, Cloud cover, Product level, Initial QC (OK/Problem), Pre-processing (e.g. filtering),DEM grid size or average distance, DEM accuracy, Result <strong>of</strong> DEM QC.• S<strong>of</strong>tware Used, Blunder check completed, Number <strong>of</strong> GCPs, Residual RMSE(metres),√PRESS(metres), Correction method (poly, ortho), Order <strong>of</strong> Polynomial, Resampling method,Output pixel Size, Number <strong>of</strong> checkpoints, Checkpoint RMSE, Maximum CheckpointDiscrepancy, Production Date, Comments, Operator name.Further in<strong>for</strong>mation should include:• input <strong>and</strong> output file names, sources <strong>of</strong> ground control, projection details, detailed results <strong>of</strong>the DEM checks, corner co-ordinates <strong>and</strong> result <strong>of</strong> visual QC signed <strong>and</strong> dated by asupervisor.It is strongly recommended that a paper pro-<strong>for</strong>ma designed to record all the in<strong>for</strong>mation listed aboveis devised by the contractor, there should be one <strong>for</strong>m <strong>for</strong> each output image <strong>and</strong> the relevant datafrom these can then be entered into the metadata database.A procedure should be applied to ensure that the final product is clearly labelled as such <strong>and</strong> that thein<strong>for</strong>mation retained in the QCRs is that which applies to this final productContractors will generate the QCRs identified above <strong>for</strong> their Internal QA. They should be madeavailable <strong>for</strong> inspection during a quality audit. The type <strong>of</strong> quality audit is shown in Table 10 as“Normal” or “Tightened” (see 2.3).